Marcopolo

Marcopolo uses Dassault Systèmes' 3DEXPERIENCE platform to centralize product data in a single environment and further master the complexity of bus development.

Custom-built Transport Solutions on a Global Scale

Brazilian mobility company Marcopolo has an unwavering commitment to excellence. Step inside its impressive headquarters in Caxias do Sul and you’ll find a team of more than 750 engineers designing bespoke transport solutions – including hybrid and electric buses, trains, trams and motorhomes. These products then are manufactured in one of the company’s 11 manufacturing facilities before being distributed to private and public sector customers in more than 140 countries.

“We are protagonists in mobility and are known for our innovative design capabilities,” Tiago Mendes da Silva, Marcopolo’s engineering coordinator, explains. “What sets us apart is our high production capacity, flexibility and ability to customize products according to the needs of our customers. If they want a bus with three bedrooms, we can make that happen. If they want their branding embroidered on every seat, we can do that, too. And we will do it while complying with the regulations that govern the markets in which they operate.”

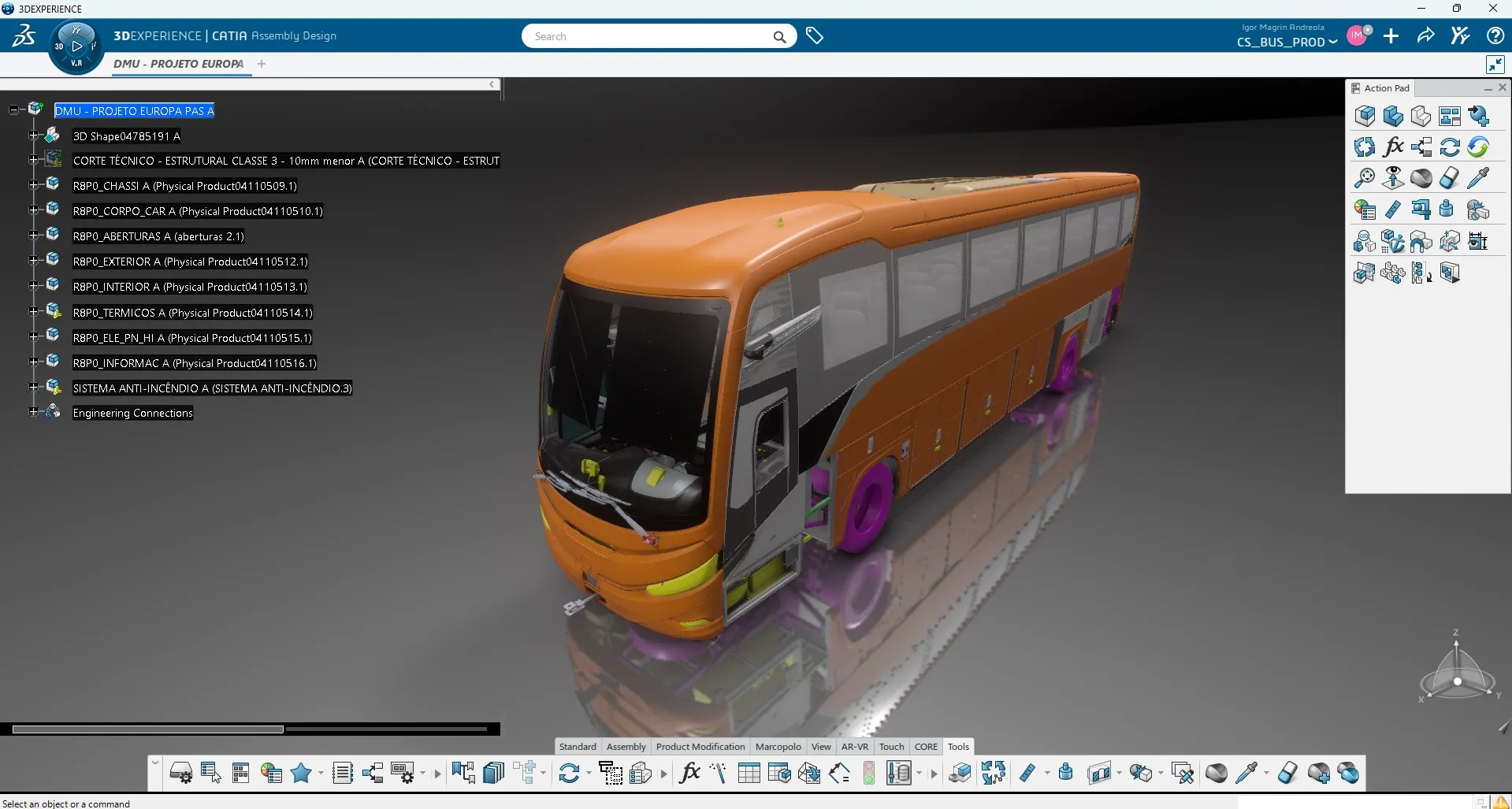

To say it’s a complex operation is an understatement. A single double-decker bus, for example, is made up of 5,000 components – each carefully designed by Marcopolo’s engineers. With tens of thousands of buses rolling off Marcopolo’s production lines every year, it’s easy to see how the company amassed a data repository of more than two million unique parts.

“On average, we create around 600 new parts every day,” da Silva said. “Designing these parts and then managing the data related to them across multiple departments, including finance, logistics and manufacturing, requires a single integrated solution. That’s why we chose Dassault Systèmes’ 3DEXPERIENCE platform.”

A single double-decker bus is made up of 5,000 components – each carefully designed by Marcopolo’s engineers. To design the parts and manage that data, Marcopolo chose Dassault Systèmes’ 3DEXPERIENCE platform.

The Path to Integration

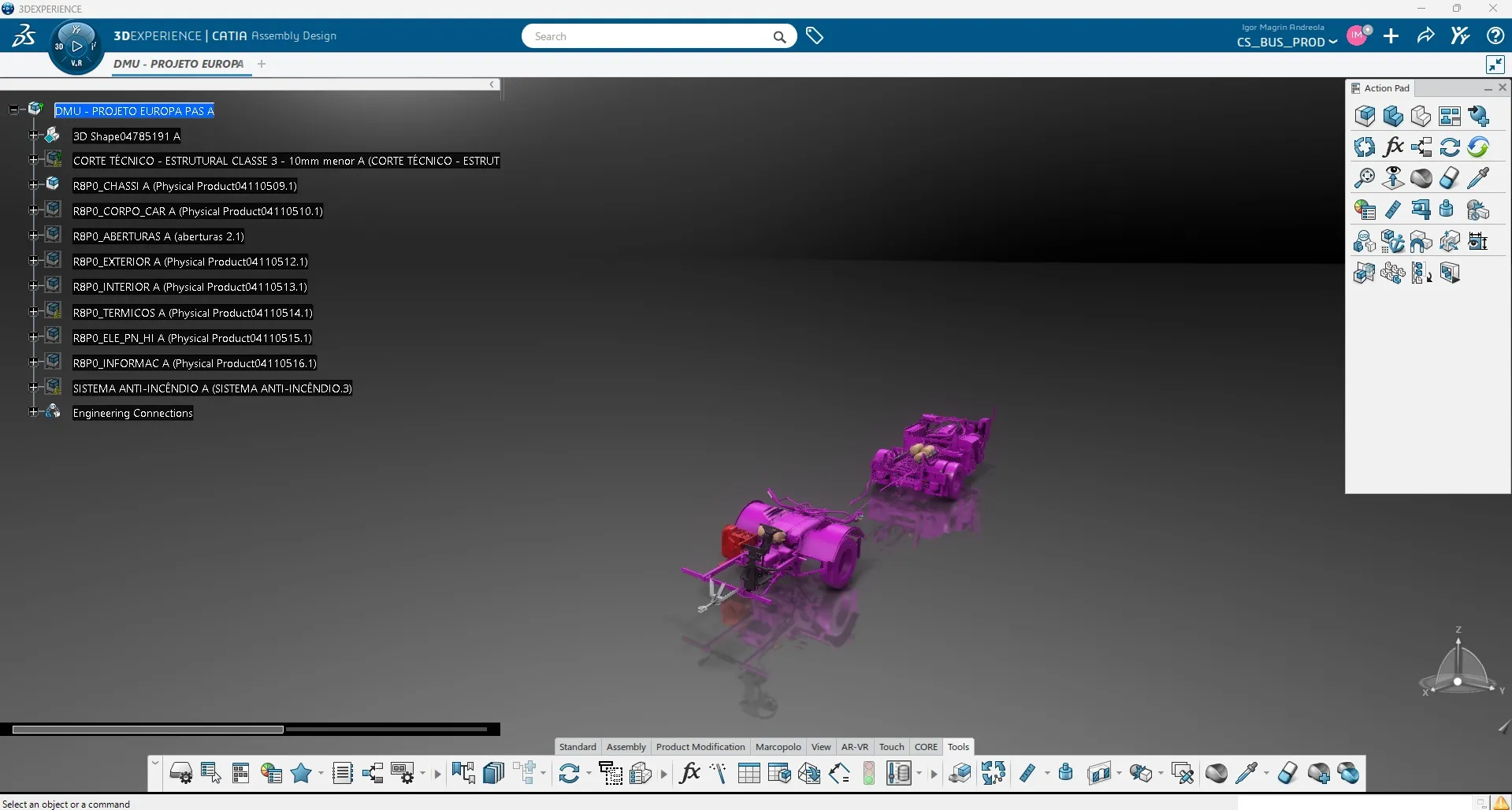

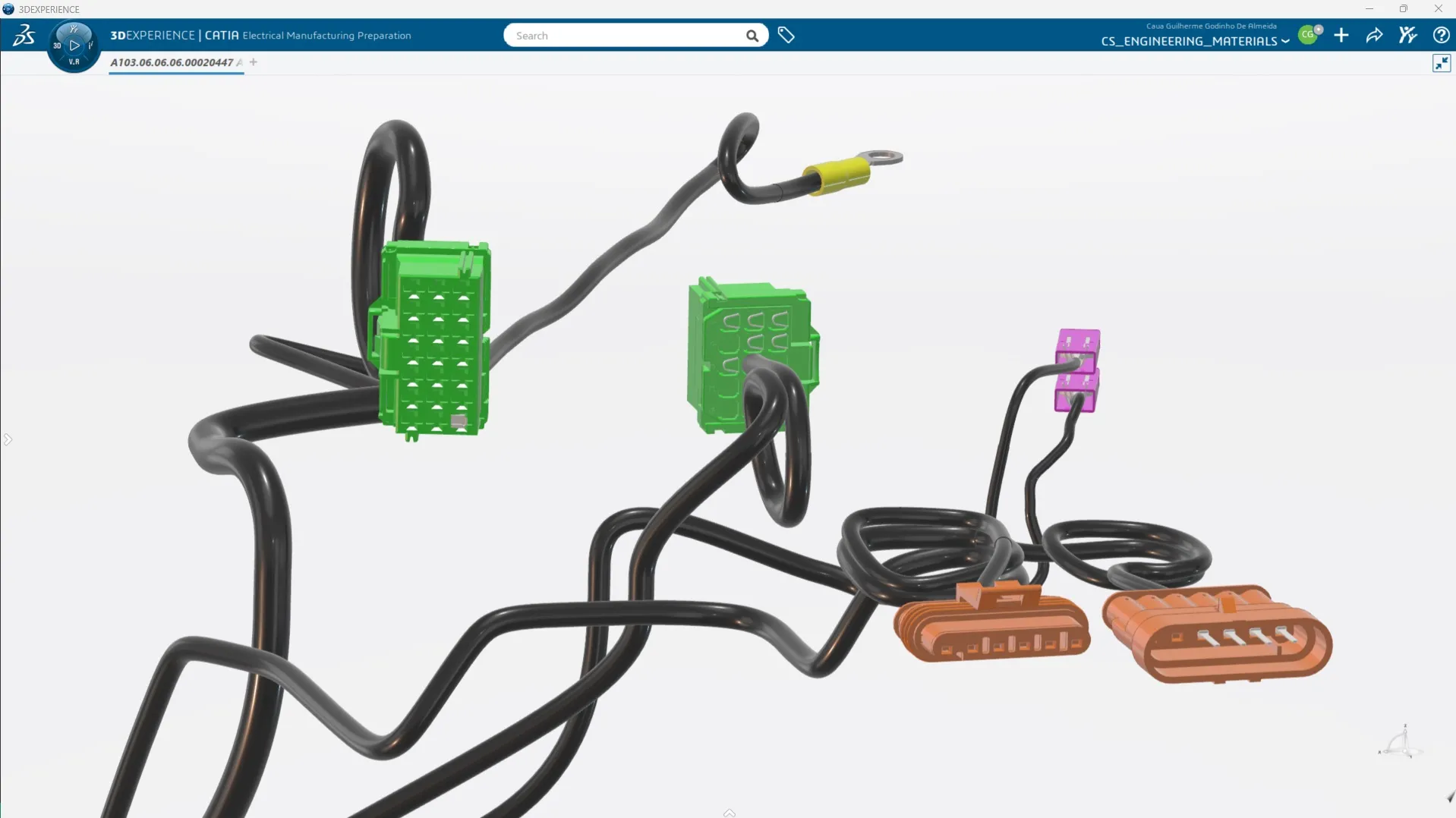

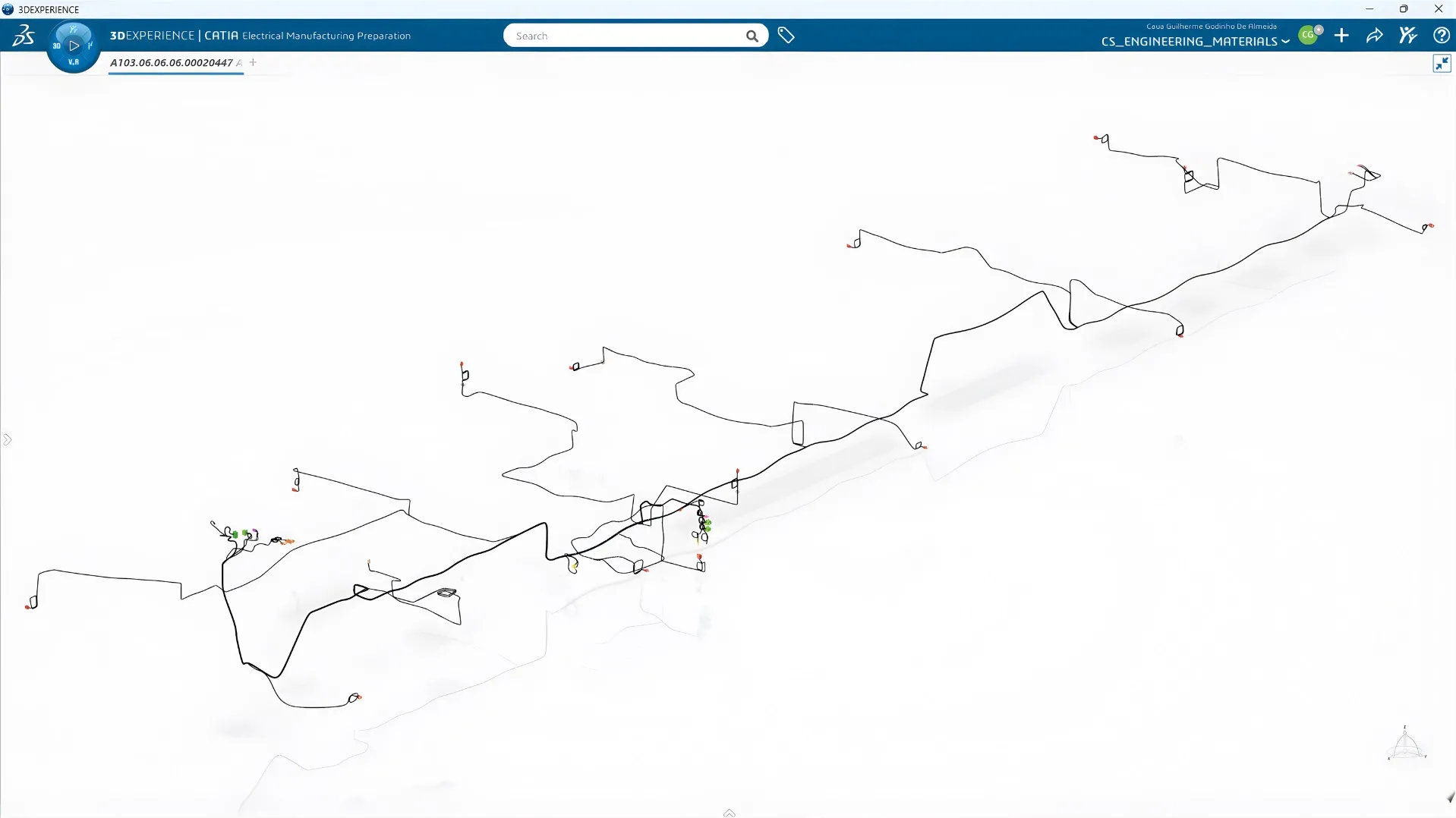

Before adopting the 3DEXPERIENCE platform, separate teams of Marcopolo’s engineers were designing individual components of its buses and other transport solutions using alternative design software. “One team would work on the body, one on the moving parts, another on the electrical parts, and so on,” da Silva said.

This siloed way of working was inefficient and costly. “The various teams weren’t able to visualize how their individual parts came together until the physical prototype stage,” da Silva said. “This could mean months of costly development work, only to realize that two parts didn’t fit together properly, resulting in rework.”

While design data from its former design software automatically synced with Marcopolo’s separate enterprise resource planning (ERP) solution, the process to move data into the company’s custom-built product lifecycle management (PLM) software was manual. From a data management perspective, having to repeatedly move between separate software solutions was not ideal – and this problem was only set to worsen. “We discovered that the upcoming version of our ERP solution would not be compatible with our existing design software,” da Silva said. “We knew that, if we were to handle our growing complexity effectively, we needed to move to a modern, integrated environment – and fast.”

Having worked with Dassault Systèmes design tools for more than 30 years – first with SOLIDWORKS, and then CATIA V5 – da Silva was keen to continue using the brand his engineers knew. Transitioning to the 3DEXPERIENCE platform – including CATIA for design and ENOVIA for product data management – was a logical choice.

“By implementing the 3DEXPERIENCE platform – which is not only compatible with our current ERP system, but also future versions – we could centralize all of our product data,” da Silva said. “We could engineer parts using CATIA, a best-of-breed design tool, and manage part numbers using ENOVIA, so everything could be done within the same environment.”

Our Generation 8 buses, which were developed entirely in the 3DEXPERIENCE platform, went to market a whole year faster than previous models. I’ve been with Marcopolo for 22 years. In the past, our leadership couldn’t have even imagined this level of efficiency. But now, thanks to the 3DEXPERIENCE platform, we’re making it happen.

Embracing Modern Design Tools

Rolling out new design tools to hundreds of engineers requires preparation. Leaning on Dassault Systèmes and its local business partner SKA for help, Marcopolo began a carefully considered change management program.

“Many of our engineers had been using the same design solutions for over 20 years,” da Silva said. “Change is hard. Before we even looked at the software, we spent two full days focusing solely on people – ensuring that everyone was on board.”

Then came training. “To shift from our existing design software to CATIA, we developed tailored training materials focused specifically on bus development,” da Silva said. “We made a rule that any new designs must be done in CATIA.”

Da Silva believes the support he got from Dassault Systèmes and SKA during this time was critical to the success of the implementation. “I have direct lines of communication with my contacts at both Dassault Systèmes and SKA, and have built very strong, personal relationships,” he said. “We speak every day – this isn’t something I’ve experienced with other software vendors.”

Transitioning to the 3DEXPERIENCE platform – including CATIA for design and ENOVIA for product data management – was a logical choice. The platform, compatible with its current ERP system, centralizes all of its product data. Marcopolo engineers parts using CATIA and manages part numbers using ENOVIA, so everything is done within the same environment.

A Single Collaborative Environment

Since implementing the 3DEXPERIENCE platform, Marcopolo has realized significant improvements in design quality, collaboration and efficiency.

“CATIA is an incredibly powerful design tool,” da Silva said. “It can handle entire assemblies, which means our engineers can now work on parts in the context of the entire vehicle, something that they were unable to do in the past.”

ENOVIA’s single source of truth means that instead of working largely independently, engineering teams now collaborate on the same, up-to-date version of a design in real time. This enabled the company to develop multiple complex products simultaneously, and with relative ease. “In the past, we’d work on only one or two major projects at a time,” Mario Veiga, manager of Product Engineering at Marcopolo, said. “Now, we can manage multiple projects simultaneously, with up to 70 people working on a single bus project.”

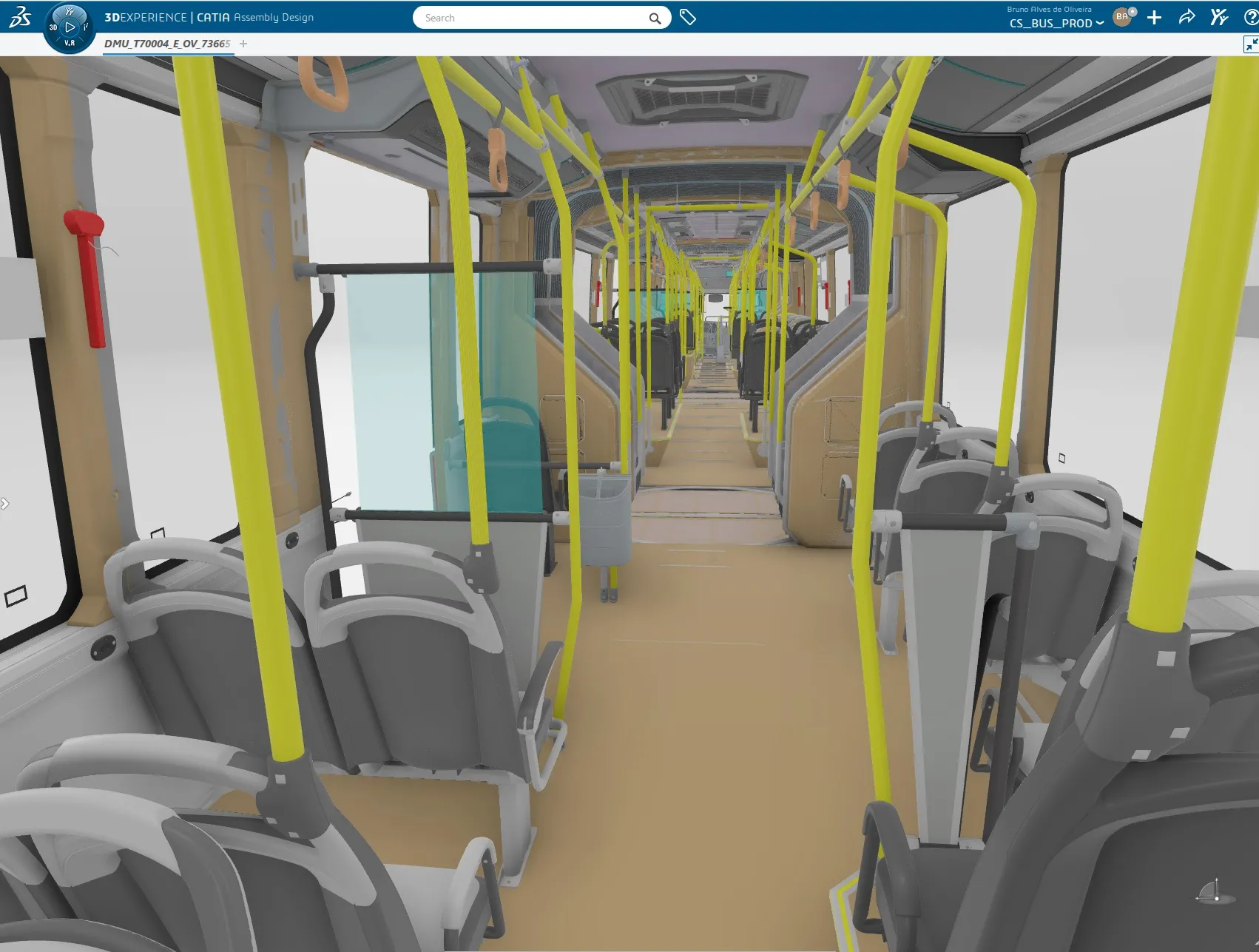

The validation process also is transformed. Change processes are handled by ENOVIA and synchronized in CATIA. Using the platform’s digital mockup (DMU) capabilities, engineers can then create an accurate 3D representation of a vehicle. And because the platform allows for real-time updates across teams, if one engineer changes a part, it’s automatically reflected in the DMU. Engineers and other stakeholders from across the business then can collaboratively review, analyze and validate the DMU before physical prototyping.

“Engineers, project managers and business leaders can see what the vehicle will look like right at the start of the project instead of waiting until manufacturing,” da Silva said. “They can even use virtual reality glasses to walk around the vehicle and experience it in a realistic way. This is a huge shift from the past when we only realized an error had been made at the prototype stage.”

CATIA is an incredibly powerful design tool. It can handle entire assemblies, which means our engineers can now work on parts in the context of the entire vehicle, something that they were unable to do in the past.

Faster Time to Market

With the 3DEXPERIENCE platform at the core of its operation, Marcopolo gained new efficiencies at every stage of development. “We estimate that we are working four times faster because we have all of our data in one place,” da Silva said. “Meanwhile, because we can now validate our products using a 3D DMU in ENOVIA, we have reduced engineering errors by 30% and reduced the cost of physical prototyping at the same time.”

As a result, Marcopolo has dramatically reduced time to production, specifically a 50%-time reduction in its prototype production process. “Our Generation 8 buses, which were developed entirely in the 3DEXPERIENCE platform, went to market a whole year faster than previous models,” da Silva said. “I’ve been with Marcopolo for 22 years. In the past, our leadership couldn’t have even imagined this level of efficiency. But now, thanks to the 3DEXPERIENCE platform, we’re making it happen.”

Improving Production Processes and Beyond

Marcopolo is rolling out the 3DEXPERIENCE platform to its production facilities, with three of its plants in Brazil using it on the shop floor.

“Production workers can access the 3DEXPERIENCE platform via tablets,” da Silva said. “We’ve also set up large displays in strategic points throughout the plant to show information about key production process, such as the chassis assembly and the assembly prototypes. We plan to roll out the platform in our Mexico and Colombia plants next year.”

Once fully rolled out, Marcopolo will unlock even more of the platform’s capabilities on the shop floor. For example, it plans to use DELMIA to help it move from manual to automated processes. “We are currently developing around 80 robots for our plant,” da Silva said. “In the next six months, our process team will start using DELMIA to program and optimize these robots, and to simulate work cell design.”

This is just the start of things to come. Marcopolo now is leveraging the platform’s capabilities to create a first-of-its-kind product configurator that it believes will be transformational for the industry.

“Right now, our configuration process is complex, and it’s difficult for customers to fully understand the multitude of options and pricing available to them,” da Silva said. “With the 3DEXPERIENCE platform, we believe we can automate much of this process through an online solution that will allow our customers to choose from two million possible configurations. By enabling customers to configure their own vehicle online, we will not only simplify the purchasing process but accelerate product development even further. It will make life easier for everyone.”

With Dassault Systèmes as its strategic partner, Marcopolo will continue to innovate long into the future. “We are committed to being responsible leaders in the electric vehicle space, and we are excited about how the 3DEXPERIENCE platform will support our next-generation projects,” da Silva said. “Together with Dassault Systèmes, we’re building the future of Marcopolo, one step at a time.”

Discover more about the Global Modular Architecture industry solution experience.

Focus on Marcopolo

Founded in 1949, Marcopolo ranks among the largest manufacturers of buses in the world. The company is committed to the future of mobility and is attentive to the development of new modes of sustainable transport. It continuously invests in improvement, technology, design and expansion, producing solutions that contribute to the development of collective passenger transport. With factories on five continents, the company’s vehicles can be found on the roads of over one hundred countries.

For more information: https://www.marcopolo.com.br/en

Focus on SKA

As a Dassault Systèmes partner in Latin America, SKA delivers products and services that drive the digital transformation of businesses and people in Brazil. With a focus on more than just systems, the company delivers innovation and support, from implementation to continuous system optimization. In doing so, it puts its mission into practice: connecting people, processes and technologies. Today SKA serves more than 5,000 clients who operate across 20 different segments.

For more information: https://www.ska.com.br/