Equal

Equal was able to collaborate from design to engineering with the 3DEXPERIENCE platform on Cloud. The Korean startup could speed up their prototype design processes and bring their electric vehicle to market in record time.

Accelerating designing speed

A fast and efficient process minimized the chance of errors, and enabled Equal to refine two prototypes before launching the third prototype as their core product, the LOFI III.

- 3 months

LOFI I

- 5 months

LOFI II

- 9 months

LOFI III

The electric vehicle race to net zero

To achieve carbon neutrality by 2050, Korea – like every nation across the globe – needs to take major action around sustainability. Transport and logistics are key areas of focus, since the logistics industry currently accounts for almost a quarter (24%) of global CO2 emissions, a number that is expected to rise to 40% over the next three decades if not addressed.

Recognizing this, Equal – a start-up company incubated at Korea University’s Maker’s Space – is delivering on a game-changer in the logistics industry.

“Our goal is to get a head start in the mobility and logistics market amid the escalating need for sustainability,” said Noh Youngjo, CEO at Equal. “We have developed a low-floor, lightweight and compact electric truck designed for the transportation of freight in factories and, eventually, in urban areas too.”

Whereas the lorry concept was created for the transportation of larger loads, the LOFI III is aimed at independent contractors and freelancers who need to transport small loads. “Our electric truck will not only be sustainable, but also affordable to rent,” Youngjo said. “It’s designed to solve many user pain points as well, such as being able to run on steep slopes and narrow alleys without any problems. It’s these features that set us apart from the competition.”

Breaking the mould in this way, however, is no easy feat. Youngjo and his team quickly realized that they needed better design capabilities if they were going to succeed.

“Because this product is so original, we had to design and engineer every component from scratch,” Youngjo said. “Our previous solution couldn’t facilitate this, resulting in far too much manual work. We needed a technology platform that was powerful enough to match our needs.”

The greatest strength of the 3DEXPERIENCE platform is its ability to enable true collaboration. We’ve been able to minimize time-consuming manual work and make the design process more efficient and faster by connecting design, engineering and system engineering using digital threads.

The power of a platform

Youngjo and his colleagues began looking for a cloud-based 3D modelling platform that their design team could pick up quickly. It had to enable multiple, geographically dispersed designers to work simultaneously, and also facilitate file sharing between suppliers and external stakeholders – most of which would be using different systems.

These weren’t the only stipulations. “As well as being comprehensive, the solution had to be affordable,” Youngjo said. “As a start-up, we could not afford to build our own infrastructure, such as servers, data management and security, because of space and budget constraints. We needed an enterprise-grade solution that could bring our designs to life, but without a huge outlay.”

It was a big ask, but Equal concluded that the 3DEXPERIENCE platform on Cloud was the perfect fit to fulfil its requirements. “We didn’t hesitate in our choice of platform,” said La Jongshin, Equal’s design director. “It was available via the cloud, meaning that we could easily share 3D design models and design data. We could even integrate the components we are getting from third parties – such as electrics and batteries – into the design.”

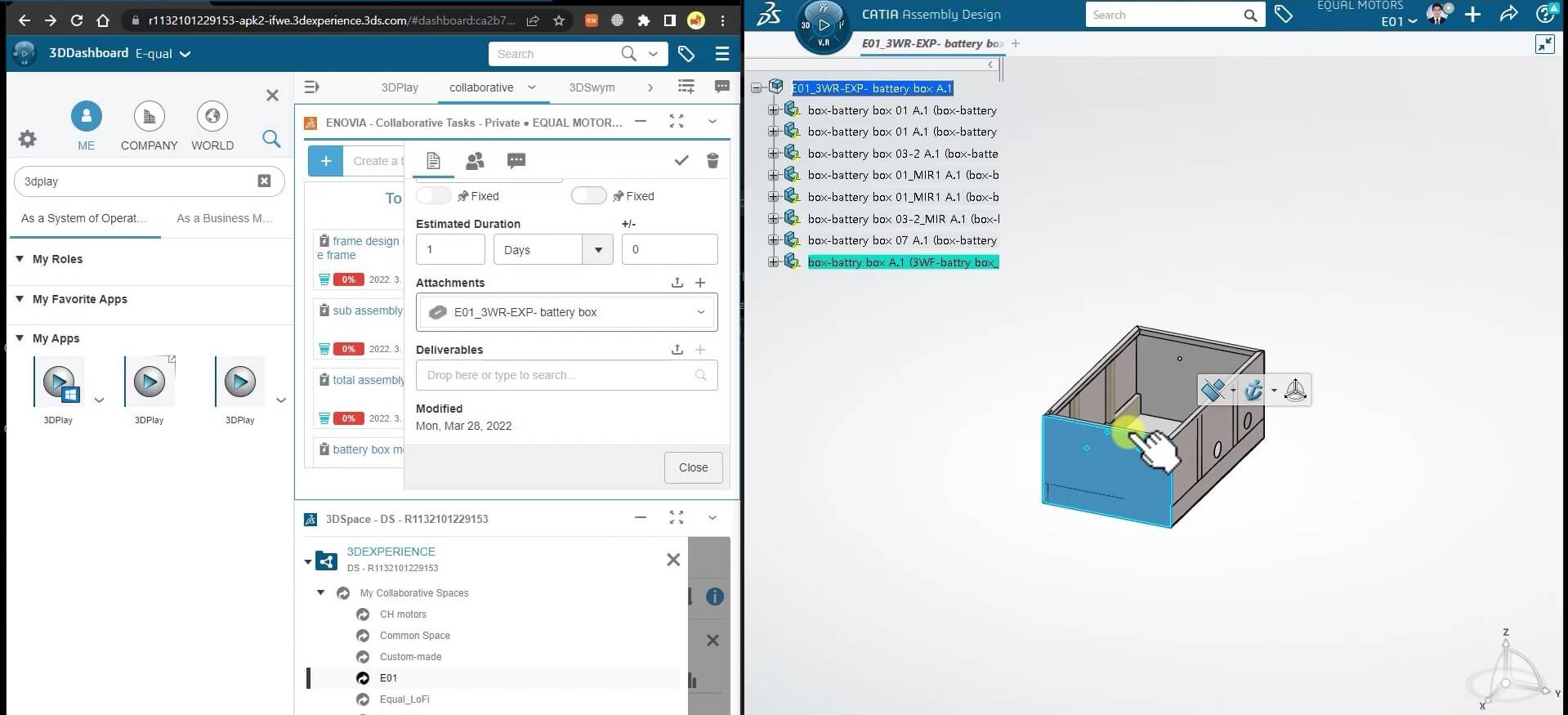

Implementation was fast and easy, so Equal began to realize the benefits of the 3DEXPERIENCE platform right away. Using CATIA, it was able to design many components of the LOFI III, including the motor housing, controller, brakes and chassis, and then assemble them into a single model. SIMULIA, meanwhile, is used for linear static simulation to validate the various parts’ strength.

“We performed part-by-part analysis, which allowed us to build a hardware platform with a stable reverse three-wheel structure. We managed to achieve a lower average height of 650mm in the loading box compared to a regular one-ton lorry,” Youngjo said. “We also managed to reduce weight with a simple drivetrain, rear wheel suspension and fiber-reinforced plastic, while increasing braking, turning and driving stability. The LOFI III’s center of gravity is further lowered by incorporating its battery at the bottom of its bodywork.”

Instead of going in and out of separate apps, you have direct access to all the tools you need, all within the same platform… Having an interface where I can proceed in a click gives me 10 to 20% higher productivity.

Teamwork made easy

The design team and design engineering team completed the design by exchanging 3D design models and related data in response to changing requirements. The team made full use of ENOVIA’s capabilities embedded in the 3DEXPERIENCE platform on Cloud, particularly its task management, maturity control and version control features. “The greatest strength of the 3DEXPERIENCE platform is its ability to enable true collaboration,” Youngjo said. “We’ve been able to improve the design process by connecting design, engineering and system engineering.”

The team benefits from the fact that they can synchronize data in real time and simultaneously modify designs in CATIA, even if designers are working from different locations. Further efficiency benefits are achieved by working in a more centralized manner. “Instead of going in and out of separate apps, you have direct access to all the tools you need, all within the same platform,” Jongshin said. “Having an interface where I can proceed in a single click gives me 10 to 20% higher productivity.”

Youngjo is particularly impressed with the ability to easily assign and manage tasks, and provide full visibility during project management. Since CAD data can be added into a task, designers never get confused about which model to modify. “I think this feature can significantly increase job efficiency,” Youngjo said. “When we used to exchange files via emails, we’d need to manually check that the data was up to date and error-free. We don’t need to worry about this anymore – we have full version control.”

Additional collaboration benefits come in the form of 3DSwym – an online collaboration community that allows users to post ideas and interact with colleagues as projects progress from concept to reality. “When I write something in the community, the platform sends a notification and keeps a record of all work-related matters,” Yeong-jo said. “It’s also very useful to ask and get an answer that would otherwise take a long time to find using a search engine.”

Working collaboratively in the cloud, designers are also able to perform part-by-part analysis, data assembly, and driving tests right within the platform. “We can play around with ideas and innovate easier,” Jongshin said.

Strengthening stakeholder relations

Collaboration with external stakeholders is also seamless with the 3DEXPERIENCE platform. “CATIA is widely adopted in the industry,” Jongshin said. “It means our many partners can proceed with the design process more efficiently, and with a much better understanding since they can access 3D model views and a wealth of data in the platform. Conversely, the models from external design partners can easily be integrated into our 3D designs.”

The 3DPlay widget has also proved useful. Using this, Yeong-jo is able to check design progress in real-time at any time, but without opening the 3D models in a rich native app. “Using 3DPlay can save the time of running CAD, which in turn helps reduce review time by quite a lot,” he said. “I can make a mark where modification is needed and insert text. From my point of view, it’s one of the most easy-to-use features on the platform.”

The Equal team is also able to use 3DPlay to easily share their 3D models with researchers in the Department of Automotive Engineering at Kookmin University – a key partner offering technical advice. “We can even connect the app to a 3D printer so the researchers can review and validate our designs far more easily,” Youngjo said. “Overall, I’d say our use of Dassault Systèmes’ design tool has given external stakeholders greater trust in us.”

3DEXPERIENCE for Startups is a great opportunity to use reliable design tools such as CATIA.

The path to a sustainable future

Using the 3DEXPERIENCE platform on Cloud, the Equal team created an advanced prototype of an innovative three-wheel electric vehicle called the LOFI I in three months. Within five months, the second prototype – the LOFI II – was developed. And in just nine months their third and final prototype was unveiled – the LOFI III, a customizable electric truck that offers modular configurations. Customers can choose the length of the truck, whether it is open or closed – or even if they want a refrigeration compartment.

“We’ve only been able to achieve such accelerated R&D and commercialization because of our adoption of Dassault Systèmes’ software,” Youngjo said. “The 3DEXPERIENCE platform has transformed the way we operate. We now have a much more simplified design process, which is enabling us to work far more efficiently.”

In December 2022, the LOFI III will be completed. Performance testing and verification, as well as certification by the Ministry of Land, Transportation and Environment, will enable it to develop a mass production plan. While significant, this is just the first step in Equal’s vision for the future.

“We are currently building a solution that verifies design data in a virtual reality environment, and we plan to design for mass production with several external partners in the future,” Youngjo said. “By 2024, we will integrate robotics into our solutions, resulting in a partially autonomous vehicle that offers greater safety in logistics. All this has been made possible by the 3DEXPERIENCE platform. Without it, I honestly don’t know where we’d be.”

Focus on Equal

Established in 2020, Equal is a Korean startup on a mission to develop sustainable, lightweight and compact electric trucks to be used for workers in the gig economy. Based at Korea University’s Maker Space, the company has been recognized for its business competitiveness and attracted investment from Futureplay, a high-tech startup investment company, just six months into its establishment.

For more information: e-qual.kr/index_en.html