Dot Foods

Dot Foods implemented DELMIA Quintiq as a comprehensive planning solution to optimize its route planning, truck loading and warehouse operations.

DELMIA Quintiq plays a vital role in helping us maximize the efficiency of these resources, optimizing transportation and logistics to keep everything running smoothly.

Mastering a complex food supply chain

In Mt. Sterling, Illinois, Dot Foods’ warehouse hums with activity as trucks laden with meat, dairy, snacks and beverages roll in and out, bound for destinations across the US and beyond. The scale of Dot Foods’ food supply chain operation is vast: the company stocks over 120,000 food and non-food product SKUs and transports them hundreds of miles across states to distributors, retailers and restaurants. Inside its two million square-foot warehouse, everything needs to be meticulously planned – from product storage to logistics – to guarantee on-time delivery to its customers.

Tackling this logistical conundrum requires more than human effort. Dot Foods relies on Dassault Systèmes’ advanced planning solution, DELMIA Quintiq, to help coordinate and optimize every part of its supply chain operation, getting food and non-food products where it’s needed, fast and efficiently.

“We deliver over 3.5 billion pounds of food annually, supported by 1,800 trucks and drivers,” said Brian LeDuc, CIO of Dot Foods. “We have around 6,500 employees, most of whom work in warehouses or on the road to distribute food and food-related products to anyone, anywhere, throughout the US. DELMIA Quintiq plays a vital role in helping us maximize the efficiency of these resources, optimizing transportation and logistics to keep everything running smoothly.”

Optimized and sustainable logistics

At Dot Foods, the journey from warehouse to customer hinges on logistical precision. DELMIA Quintiq addresses this by tackling two critical areas: optimizing truck routes to ensure timely arrivals and keep mileage to a minimum; and coordinating the movement of products within the warehouse.

Dot Transportation Incorporated (DTI), the logistics affiliate of Dot Foods, handles the complexities of route planning and load management across the company’s distribution network. It coordinates thousands of deliveries and transports all products to customers via a fleet of 2,500 trucks. To support the logistics, DELMIA Quintiq enables effective route planning, making sure that products reach customers on time, at a competitive price and in the most sustainable manner.

“The scale of our operations, the sheer number of products and trucks, and the numerous variables involved meant we needed the best solution to manage all this complexity,” LeDuc said. “DELMIA Quintiq helps us plan truck routes efficiently, ensuring timely deliveries and keeping mileage down.”

The environmental impact of logistics operations is a growing concern and Dot Foods is committed to reducing its carbon footprint across its supply chain. By optimizing routes and avoiding unnecessary miles, DELMIA Quintiq plays a direct role in lowering emissions from DTI’s fleet.

“Effective route planning not only saves money, but also helps reduce emissions,” LeDuc said. “The more miles we save by planning better routes, the less pollution our trucks emit, which is critical to our sustainability goals.”

Real-time adaptability for better service

One of the standout features of DELMIA Quintiq is its ability to automatically adapt to changes in real time. This revolutionizes how DTI manages different customer orders – making best use of every truck and journey without compromising on service quality.

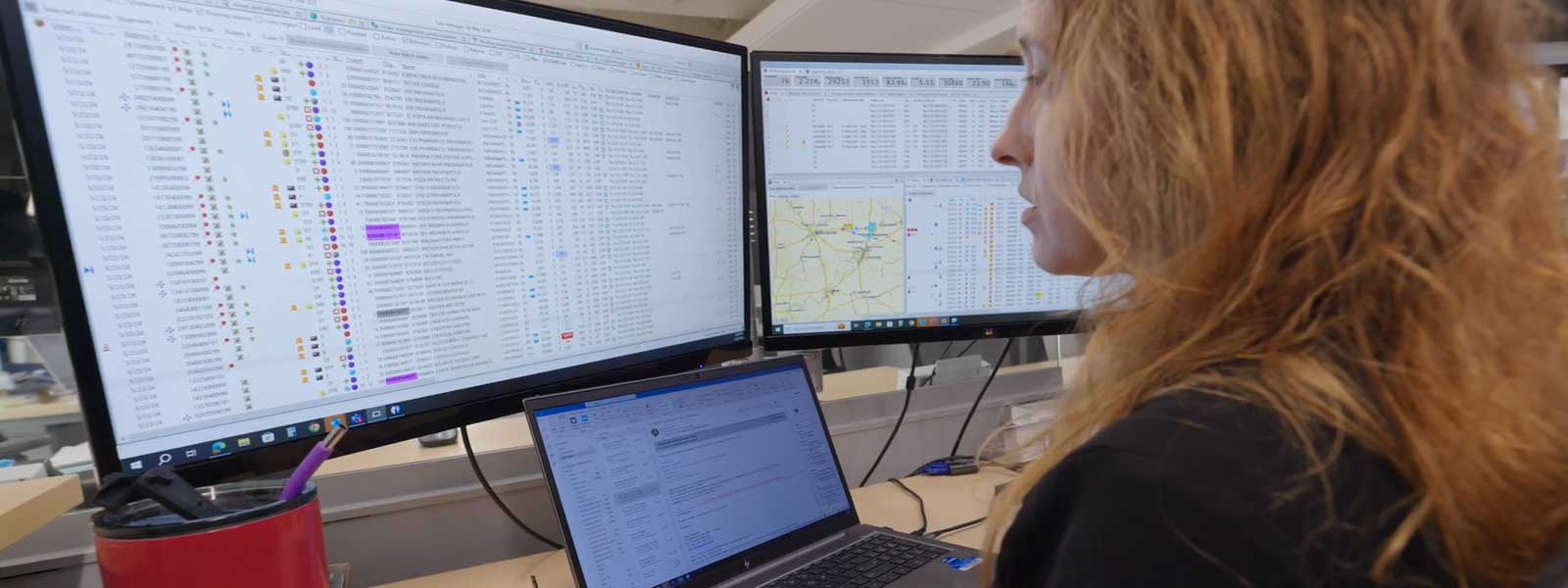

“DELMIA Quintiq’s route-building capabilities allow us to input all relevant variables and combine orders from different channels on the same truck while still meeting unique delivery requirements,” said John Ourth, director of planning at DTI. “We can add, modify or remove orders as they change in real time. Previously, batch uploads would quickly become outdated due to frequent adjustments, but DELMIA Quintiq has solved that challenge. Now, our planning is always accurate and up-to-date.”

Working with real-time data and visualizing the impact of any changes across the supply chain ahead of time is a breakthrough for DTI, especially in terms of problem solving. The system adapts automatically, improving route planning and trailer space utilization. DTI can make faster decisions and involve more people in the process.

“We’re operating at all-time highs,” said Chris Wisslead, director of logistics at DTI. “As far as trailer space utilization, we’ve been able to see a lot more of the variables that we can now incorporate and plan for. It’s been a game-changer in terms of both customer service and cost management. We’re getting the product there on time, but also managing costs and improving employee satisfaction – getting our drivers back home to their families faster.”

We’re operating at all-time highs. As far as trailer space utilization, we’ve been able to see a lot more of the variables that we can now incorporate and plan for. It’s been a game-changer in terms of both customer service and cost management. We’re getting the product there on time, but also managing costs and improving employee satisfaction – getting our drivers back home to their families faster.

Streamlining warehouse operations

Inside the warehouse, DELMIA Quintiq helps streamline the movement of goods – and people – within the two million square-foot space, organizing customer orders and quantities for quick and efficient picking and loading. Dot Foods applies the same strategic planning it uses for routing trucks on the road to orchestrate operations internally. This includes scheduling the transfer of pallets from automated to manual workflows and keeping unnecessary travel to a minimum.

“Today, at any given time, we have around a thousand employees in Mt. Sterling who could be traveling all over the warehouse,” said Chris Landrum, vice president of warehouse at Dot Foods. “We realized that we could optimize not only our transit routes but also the movement of products within the warehouse itself, which is crucial given its size. DELMIA Quintiq helps us reduce the amount of travel required to pick customer orders for each day and make the transition seamless between automated and manual processes.”

This connected approach allows Dot Foods to align workforce availability with operational needs – assigning tasks, adapting schedules in real-time and factoring in variables such as skill sets and workload balance.

“Our priority is to reduce lead times and have more flexibility in our work schedules,” said Troy Schenk, director of automation at Dot Foods. “Now, we evaluate the team members' availability, assign them the most appropriate tasks and plan their day accordingly.”

As Dot Foods adds new automation and continues to scale, so does the complexity of its operation. Even though its warehouses are more automated, manual processes will still play a significant role in making sure products are packed and shipped accurately. DELMIA Quintiq bridges the gap between the two and ties everything together.

“It serves as the critical software layer that integrates all these elements seamlessly, bringing our manual and automated processes into one cohesive system,” Schenk said.

Balancing customer service, cost and sustainability

Since partnering with Dassault Systèmes, Dot Foods has experienced significant improvements in its operational efficiency, cost management and environmental footprint. This allows the company to continually balance exceptional customer service with cost management and sustainability, and stay ahead in an increasingly competitive and environmentally conscious landscape.

Dot Foods’ culture of continuous improvement is central to its success. The company is always looking for ways to enhance its supply chain, whether it’s through better planning, optimized routes or more efficient warehouse processes. As Dot Foods continues to expand its network and operational scale, its partnership with Dassault Systèmes remains a cornerstone of its growth strategy.

“The team at DELMIA Quintiq has been wonderful to work with,” Ourth said. “They’re like family to us. Their support and understanding of our needs have been invaluable. Together, we’ve been able to overcome the complexities of our business and create a solution that drives efficiency and sustainability.”

Focus on Dot Foods

Founded in 1960 by Robert and Dorothy Tracy, Dot Foods is North America’s largest food industry redistributor and one of the nation’s largest private, family-owned businesses. With 13 US distribution centers and two locations in Canada, Dot serves all 50 states and over 50 countries. Built on a foundation of trusted values and innovative solutions, Dot Foods continues to focus on shared growth, integrating its founding principles into every aspect of its operations and partnerships.

For more information: www.dotfoods.com