Cavo Otomotiv

Turkey-based automotive safety systems supplier Cavo implemented the Bid to Win industry solution on the 3DEXPERIENCE platform for continuous product development as well as data and document management. Improving its productivity and collaboration, Cavo has shortened its product development process and has now the time it needs to focus on its business growth.

Building resilience with digitalization

Success in the automotive industry requires a high level of resiliency, not only to adapt to the unprecedented speed and volume of change, but also to achieve optimized and profitable outcomes. In this context, Turkey-based supplier Cavo Otomotiv wanted to improve the way it operates to provide a better service to its customers. Founded in 1984, the multinational company designs and manufactures safety products, mechanisms and operating cables, supplying major global automotive companies – each of which has different expectations.

“They all have their own data management system, design rules and procedures,” said Mustafa Yılmaz, product design responsible at Cavo. “At the same time, OEMs are always looking for cost and weight reductions but with the same quality and durability, which was getting difficult to keep up.”

To stay one step ahead of the competition, Cavo was looking for a new technology platform that could help it become more efficient and productive. The company needed a data management system that could help it to meet customer expectations and work in a more organized way to free up time to think about the ongoing development of its business.

The 3DEXPERIENCE platform is an attractive option because of its ability to bring all stakeholders together into a common environment and to create a single source of truth where all data revisions are up to date.

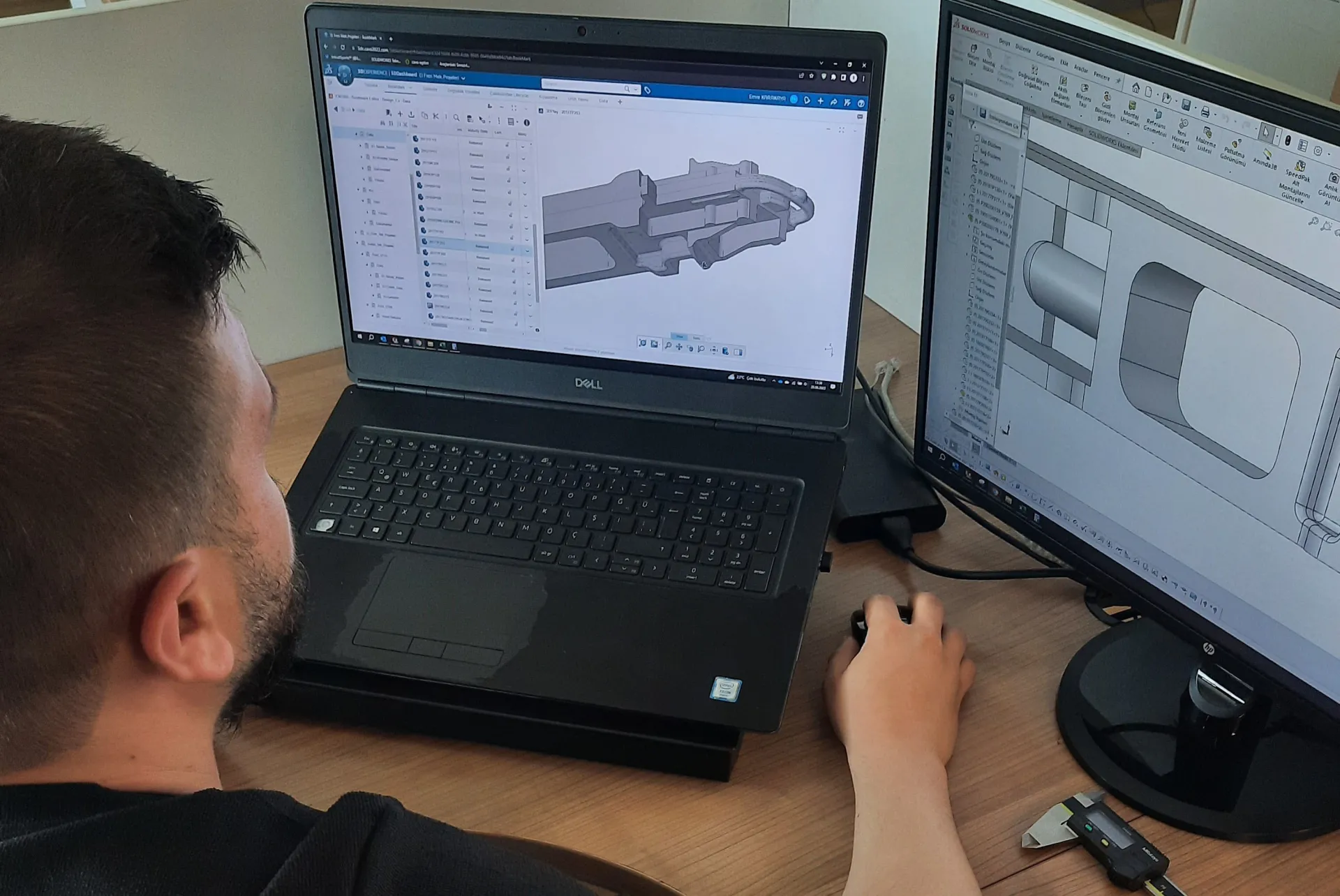

Historically, engineers at Cavo have been designing with Dassault Systèmes’ CATIA and SOLIDWORKS applications. With that in mind, adopting the 3DEXPERIENCE® platform was the logical next step.

“The 3DEXPERIENCE platform is an attractive option because of its ability to bring all stakeholders together into a common environment and to create a single source of truth where all data revisions are up to date,” Yılmaz said.

Having already worked with Dassault Systèmes’ local partner infoTRON on various projects, Cavo sought its expertise for this implementation also. Leveraging Dassault Systèmes’ Value Engagement model, infoTRON set about determining exactly what Cavo needed to achieve to make its business more agile, resilient and sustainable. At first, infoTRON carried out an on-site assessment to determine Cavo’s requirements. The partner understood the needs of both Cavo’s management and R&D teams. It then ran the definition phase and did a variety of proof-of-concepts to illustrate how Cavo’s main issues could be met with an out-of-the-box approach.

“It took around five months to complete the first phase of the project, which included the legacy data integration and release process,” Yılmaz said. “infoTRON provided us with training and also documented the key processes to be used in the 3DEXPERIENCE platform, sharing tangible and practical examples. Whenever we faced an issue, infoTRON responded quickly with a solution. After we went live, we have been supported both onsite and online to ensure that we are running the system without issues.”

A common platform for growth

Today, Cavo is experiencing a wide range of benefits as a direct result of implementing the 3DEXPERIENCE platform. It is using ENOVIA and CATIA apps for continuous product development as well as data and document management. Because Cavo is now leveraging a single solution, its design engineers are more aligned in their work.

“Thanks to ENOVIA, we can develop products collaboratively, with the same technical language, which helps us accelerate our design process,” Yılmaz said. “We are able to follow and manage our customer and R&D projects in parallel, backed by the collaboration space feature of the 3DEXPERIENCE platform.”

At the same time, having a single engineering definition and bill of materials (BOM) has delivered additional benefits, including improved data management.

“Using the platform, we monitor the progress of 3D models in real time,” Yılmaz said. “That means we can react quickly when changes are required. Thanks to the engineering BOM (e-BOM) we now have, we can manage 3D data in line with multi-CAD-based developments and revisions in a single web interface. This makes it easy to evaluate our designs as they progress. What’s more, since we started to use the e-BOM module in the 3DEXPERIENCE platform, the data sharing process among engineers is also much safer.”

Connectivity with existing SOLIDWORKS data is secure – and straightforward too.

“The Derived Format Converter tool enables us to generate derived formats, for example STEP or PDF, from SOLIDWORKS files,” Yılmaz said. “This means that non-CAD users can access technical drawings and data, speeding up collaboration.”

Since Cavo can now control, review and revise data instantly and as necessary using CATIA, the testing and revision process is faster. Additional 3D widget tools are helping employees take action quicker and make better decisions in the development process. As a result, Cavo is no longer using emails for tracking CAD data issues.

“Using the 3D widget tools, the engineering teams can inspect the data without CAD software,” Yılmaz said. “They can take notes on the data and share them in the system with the design engineer. It’s now possible to see what iterations have been made in the data history. There are also no more unnecessary conversations while trying to decide what to do. With all communication now managed as distributed tasks, designers are continuously updated. The platform enables clear communication and accelerates the testing process which means that every stakeholder can find more time to do their tasks.”

Freeing up more time, having instant access to real-time data has helped reduce miscommunication-based errors. Successful actions and process factors are captured within the platform and can be reused in future projects. And this is not the only way successes are shared.

“Thanks to the project communities created in the 3DEXPERIENCE platform, each member has instant access to information and can share ideas,” Yılmaz said. “This has made project members more productive and accelerated the project process.”

The path to a better future

These benefits directly contribute toward Cavo’s current and future business objectives, which include developing unique product catalogs and brands as a way to continually raise the company's position as a full-service supplier to automotive manufacturers.

“We are now more innovative as a company,” Yılmaz said. “By making decisions faster, we can take our new products to market faster. This new level of efficiency means we have more time to work on our future goals. We will be able to spend time developing new products including brake pedal boxes, seat recliner mechanisms and window lifters. We can also raise the profile of our business in new markets around the world.”

As Yılmaz and his team look to the future, they are confident that the 3DEXPERIENCE platform will grow with them.

“The solution is updated regularly by Dassault Systèmes, and infoTRON keeps us up to date on new enhancements and developments,” he said. “That means we are always using the latest version of the solution. Ultimately, we believe that every input that we make in the 3DEXPERIENCE platform will pave the way for smoother and more successful future projects. Every day, we are learning from our successes and creating a library of data we can reuse. This saves us a great deal of time and effort as we move forward, and ensure we are always one step ahead.”

Discover more about the Bid to Win industry solution experience.

Focus on Cavo Otomotiv

Founded in Turkey in 1984, Cavo is a multinational original equipment manufacturer operating in the automotive supply industry. It designs and manufactures a variety of safety products, mechanisms and operating cables, serving global automotive firms. Today the company has a 15,000 square meter production facility in Turkey’s Taysad Organized Industrial zone, alongside a new R&D center. It also has a production facility in Slovakia and an engineering office in Germany and Canada.

For more information: https://en.cavo.com.tr

Focus on infoTRON

Founded in Turkey in 1994, infoTRON is a provider of technology solutions and services and a certified Dassault Systèmes Platinum partner. With its vast industrial knowledge and innovative approach, infoTRON provides the latest technology products and solutions to its customers for the most effective business results. It provides added value to stakeholders, customers and the society through technologies that enable sustainable growth and 3D innovation.