Bouygues-Thai

When Bouygues-Thai needed to design a prefabricated wall structure within a tight deadline, it took advantage of the 3DEXPERIENCE® platform on Cloud and the integration-ready module design capability in CATIA to deliver the prefabricated wall design on time, while saving costs and reducing waste.

Thanks to the 3DEXPERIENCE platform, we could work 80% faster compared to how we would have usually worked on a project like this.

Shaping Thailand's smart construction industry

Imagine a construction site where prefabricated and precut walls arrive on site at just the right time, built to the precise dimensions and shapes to fit exactly where they’re meant to go. There is no guesswork, no excess material on site, and no waste – workers have all the information they need to install the walls correctly and ensure the smooth running of the project. Without any cutting required on site, worker safety is also improved. It sounds like a construction company’s utopia, but this is the kind of reality Bouygues-Thai has worked towards with the 3DEXPERIENCE platform on Cloud.

A subsidiary of Bouygues Construction, Bouygues-Thai has made its mark on the local industry since it began shaping the development of a new city, Muang Thong Thani, over 30 years ago. Since then, it has continually embraced cutting-edge construction methodologies and technologies, both to bring efficiencies to its projects and to improve worker health and safety.

“The construction business here has evolved fast, in all directions, but especially in terms of safety,” said Patrice Bard, managing director of Bouygues-Thai. “What was once an overlooked issue has become a real priority. Working hours are now regulated and as a company we must strive to do more with the skilled workforce that we have. That involves using advanced machinery and equipment, embracing digital technology and introducing new approaches to become more socially responsible while reducing our environmental impact.”

Embedding construction knowhow into 3D models

When Bouygues-Thai was tasked with improving the design process for a prefabricated concrete wall structure, it didn’t hesitate to use the latest software to meet the brief. The company needed a design application that could turn design rules from its subcontractor, Texca Wall, into detailed 3D models and generate the associated work instructions. Bard had seen the 3DEXPERIENCE platform in action at an industry event in Bangkok and recognized the value it could bring to his company. This was the perfect opportunity for Bouygues-Thai to use Bouygues Construction’s existing 3DEXPERIENCE platform on Cloud licenses to access the design tools it needed.

“I discovered what solutions Dassault Systèmes had for the marine industry and in many ways, we share the same kinds of challenges when it comes to integrating and coordinating multiple disciplines within a single structure,” Bard said. “Once I’d seen how CATIA on the 3DEXPERIENCE platform had been used to handle a similar dry wall partition project, I knew it could help us solve our own design challenge.”

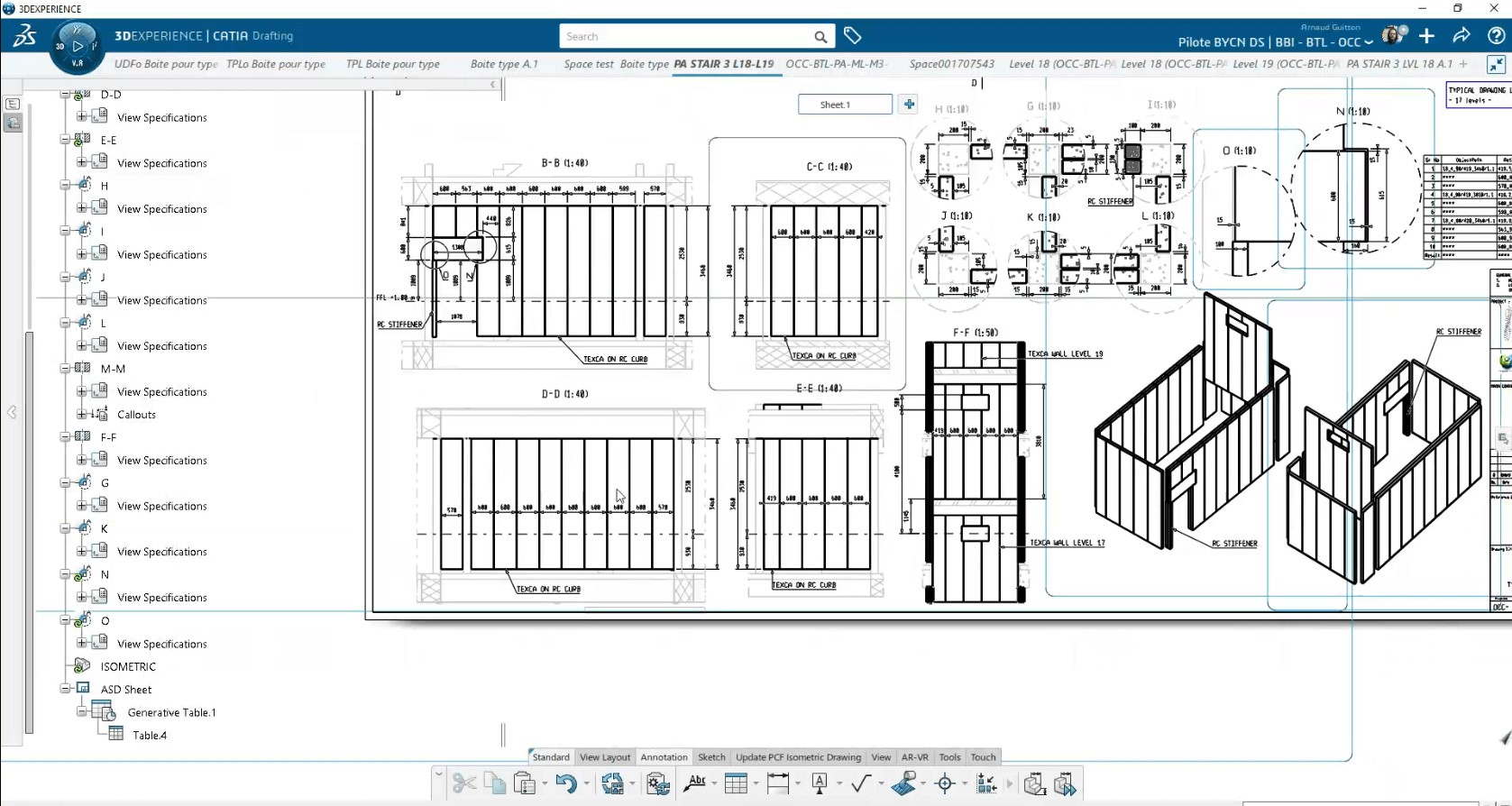

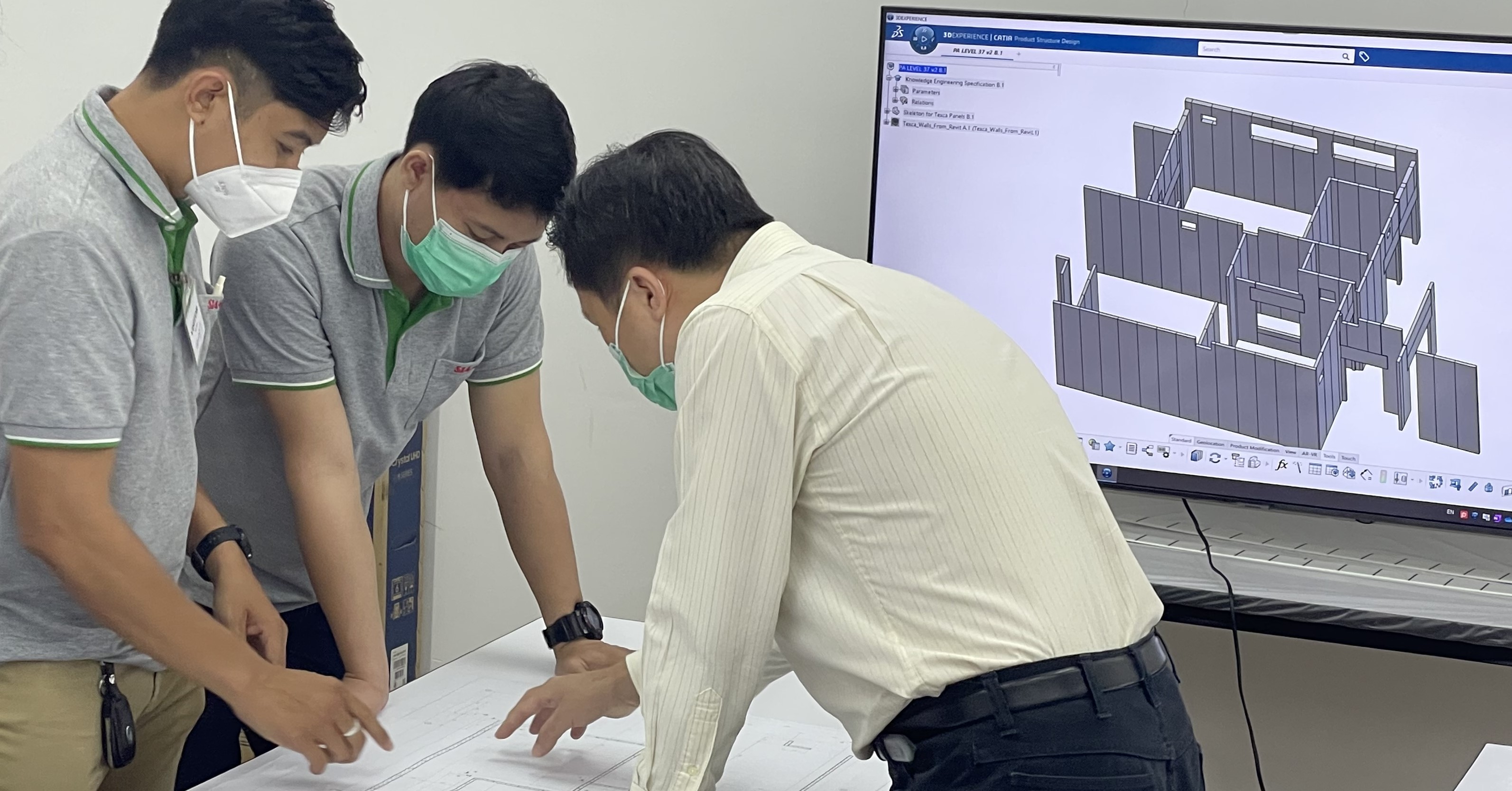

Bouygues Construction’s technology partner Impararia brought the expertise to complete the pressing project on time. It configured CATIA to automate the wall layout, and create the shop drawings and bill of materials. The approach was a step-change from the 2D drawings Bouygues-Thai and its subcontractor, Texca Wall, were used to dealing with. Thanks to CATIA, the process of designing the prefabricated walls was fast and straightforward.

“Impararia’s knowledge allowed us to transform the design rules we received from Texca Wall into software features we could use in CATIA to automatically generate the 3D models of the prefabricated wall panels,” said Jean-Francois Rouanet, design manager at Bouygues-Thai. “We were able to create the geometry within a few clicks.”

“Thanks to the 3DEXPERIENCE platform, we could work 80% faster compared to how we would have usually worked on a project like this. Texca Wall was impressed by what we’d been able to do.”

Benefits experienced from design to installation

- 80%

faster in wall design

- 50%

faster in wall installation

- 6%

reduction in material waste

Accurate design and bill of materials

Bouygues-Thai managed to not only design the wall layout for Texca Wall, but provide the quantity of panels for each floor, complete with dates for manufacturing and delivery, plan the process and virtualize assembly know-how. By having the concrete walls designed and fabricated offsite, Bouygues-Thai hoped to construct the building more quickly, efficiently and sustainably.

“CATIA allowed the team to determine exactly how much material they needed to produce each wall, ensuring they met specific technical requirements and reducing material waste by 6% by avoiding poor execution and optimizing consumption,” explained Frederic Gal, program director of business transformation at Bouygues Construction.

As a result of this preparation, combined with the perfectly designed prefabricated walls and the clear work instructions generated by CATIA, the construction stage progressed smoothly, minimizing the work required on site and shortening the construction timeline.

“The team was able to work 30% faster when installing the walls on the first floor and 50% faster on the following floors once they were up to speed,” Gal said.

“When I was working in my office on site, I saw two large wall panels arrive, already precut to precise dimensions,” Rouanet added. “They only delivered what they needed – everything was based on our designs, so no further adaptations were required.”

Being able to see the design come to life in a 3D model ahead of construction helped everyone to clearly visualize what they were working towards, both in the design reviews and the installation of walls on site.

“3D models are visually appealing and easier to understand,” Rouanet said. “You can move the walls around to see them from different angles and orientations. We could clearly show the subcontractor and on-site workers what they had to build so this element of the project moved faster. It meant that when they arrived on site, they knew what was required and there weren’t any surprises.”

The 3DEXPERIENCE platform presents numerous advantages that lead to smoother operations on the construction site. As the pressure grows for us to work faster and keep our workforce safe, we need the capabilities to plan ahead and move to a productization approach.

Reusing construction best practices

Since virtualizing construction on the 3DEXPERIENCE platform on Cloud and seeing the value it brings, Bouygues-Thai hopes to use it again in future builds.

“The idea was always to use what we’d done with the 3DEXPERIENCE platform and apply it to other projects and even use it in other regions worldwide,” Rouanet said. “We can take what we’ve learned and make small adjustments to suit other projects, so we don’t have to reinvent the wheel every time.”

Bard agreed, adding that the 3DEXPERIENCE platform is particularly well suited to the construction industry as it continues to enhance its digital capabilities and do more with less.

“Digitalization is really beginning to transform construction,” Bard said. “For us, the 3DEXPERIENCE platform presents numerous advantages that lead to smoother operations on the construction site. As the pressure grows for us to work faster and keep our workforce safe, we need the capabilities to plan ahead and move to a productization approach. I believe that’s exactly what the 3DEXPERIENCE platform can help with.”

Discover more about the Integrated Built Environment industry solution experience.

Focus on Bouygues-Thai

Bouygues-Thai came to Thailand more than 30 years ago. Since then, the company has been involved in a range of landmark projects, playing a pivotal role in the creation of Bangkok’s skyline. Bouygues-Thai is recognized as a pioneer in its industry, spearheading new construction techniques and technologies. As part of a globally respected network of construction-related companies, Bouygues-Thai has the support, resources and technical knowhow to complete the most technically demanding projects.

For more information: www.bouyguesthai.com

About Impararia

With its roots in the aerospace and defense industries, Impararia is a key player in virtual design and construction, building information modeling and product lifecycle management for the architecture, engineering and construction industry. The company delivers innovative business processes and technologies to support companies in overcoming their utmost construction challenges and producing the finest version of their work.