Airbus Helicopters

From design to certification, Airbus Helicopters uses the connected 3DEXPERIENCE platform to develop, test and refine every helicopter with advanced simulation and data management.

(Photo © AIRBUS)

Bringing Digital Continuity to Simulation Process and Data Management

In helicopter development, every design choice has critical implications. Engineers must balance performance, safety and reliability in machines that operate in the most challenging environments, from confined urban airspaces to rugged mountain terrains. Then comes certification, a process so demanding it costs tens to hundreds of millions of euros, pushing the total close to €1 billion (US$1 billion) across a commercial flight test program, according to a 2021 report from NASA (NASA/CR-20210015404 - “A Guide for Aircraft Certification by Analysis”). NASA research indicates that replacing a portion of physical flight tests with validated simulations through certification by analysis could reduce costs by around 50%.

Airbus, the leading manufacturer of civil and military rotorcraft, has more than 12,000 helicopters in service across 150 countries, performing missions ranging from emergency medical response to national defense. Each helicopter development program involves thousands of interdependent decisions and strict certification demands, requiring extensive testing and traceability. In a competitive environment, the company needs better simulation management to speed up development and certification without compromising safety and reliability. To this end, the company is moving away from isolated simulation tests to a connected, traceable approach that captures the results but also the reasoning and workflow behind each simulation.

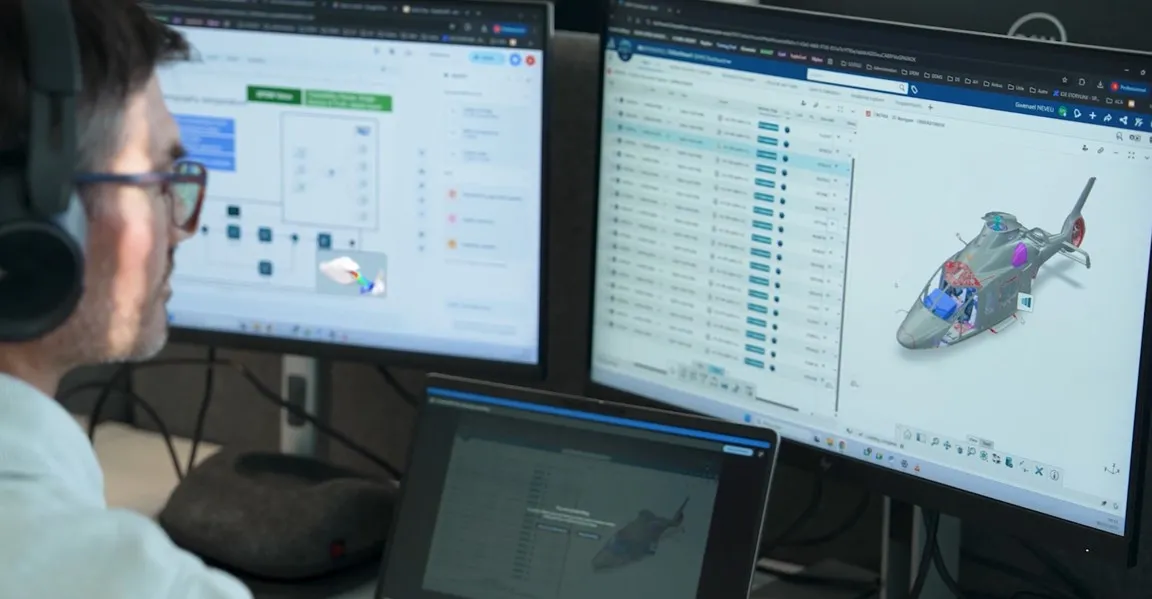

“Airbus Helicopters develops complex products and we need simulation to design and develop them,” said Gwenaël Neveu, methods and tools engineer at Airbus Helicopters. “We study many different simulations: thermal, aerodynamic, mechanical and electromagnetic. It means we have an enormous amount of data to handle. Our challenge is to perform all of these simulations and to successfully manage all of this data.”

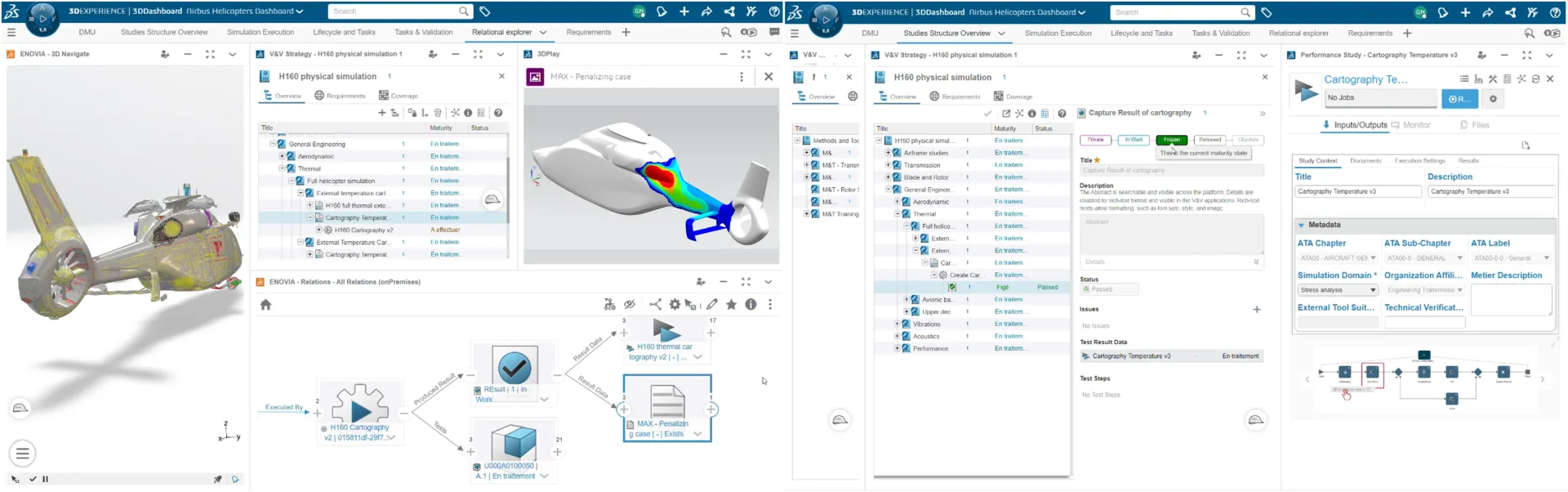

In response, Airbus Helicopters adopted Dassault Systèmes’ simulation process and data management (SPDM) solution to capture and organize information, automate workflows and achieve end-to-end traceability from simulation input conditions to final results. This makes sure that engineers aren’t starting from scratch every time and that decisions are backed by clear, documented evidence.

“The goal of SPDM is to industrialize our way of conducting simulations and meet our certification objectives,” Neveu said. “This means we will have better productivity because we will be able to eliminate unnecessary and time-consuming tasks such as data searching.”

Supporting Airbus's DDMS Program

Airbus Helicopters’ SPDM initiative is part of Airbus Group’s wider Digital Design, Manufacturing and Services (DDMS) program that maintains a continuous digital flow across all stages of aircraft development and product lifecycle management.

On the 3DEXPERIENCE, CATIA handles advanced design and engineering, shaping complex parts like rotor blades and fuselages. Coupled with SIMULIA, integrated modeling and simulation (MODSIM) capabilities allow engineers to virtually define loads, test and refine aerodynamics and other key factors. MODSIM also allows engineers to compare simulation results from different manufacturing processes in advance. They can then take the requirements of the chosen process into account from the start of the design.

ENOVIA supports teams around the world to access and share information in a single, organized system. And DELMIA connects digital design to manufacturing, integrating planning, scheduling and quality control to deliver real-time visibility, digital instructions and optimized processes. DELMIA also helps Airbus Helicopters embed a culture of continuous improvement. By capturing and analyzing operational data from the shop floor, the company can identify inefficiencies, reduce waste and standardize best practices across its global sites.

Together, these capabilities lead to faster development cycles, stronger cross-functional collaboration, richer knowledge and intellectual property, and the ability to anticipate issues before they occur on the factory floor and throughout an aircraft’s lifetime.

“Using the 3DEXPERIENCE platform to implement our SPDM solution was a no-brainer,” Neveu said. “We needed a single source of data that is accessible and shareable, where we can easily find and reuse the information we need. Also, when we execute simulations, we need to capitalize on them activity by activity, reuse them and be able to trace all inputs.”

Through SPDM, Airbus Helicopters has a single source of truth for simulation data and a structured way to run simulation workflows from start to finish. Each analysis follows the same steps and conditions, so results can be trusted, compared and reused. This creates a reliable digital thread that links design, testing, certification and manufacturing,supporting the company to bring new helicopters to market with full confidence in their safety and performance.

Towards Full Simulation Product Development Traceability

Alongside this clearly defined approach, Airbus Helicopters is building a comprehensive knowledge base that captures the full context of every study in every product development process. Simulation activities and analyses can be organized and tagged, allowing engineers to learn from past work and apply proven methods to new projects. ENOVIA records each step of the process, so teams can draw on accumulated knowledge to make faster, more informed decisions.

“Simulation plays a role throughout the helicopter’s lifecycle, from the conceptual phase to development, and then to support and service, to study operational conditions that may arise for our clients,” Neveu said. “Each simulation study must be structured with context so that it can be retrieved, reused and tracked.”

A key benefit is seeing how design changes affect the entire project. Engineers can trace how a modification in one area, such as an updated material property or new load condition, influences related simulations downstream. This gives them the confidence to decide whether further analysis is needed or if existing results remain valid.

“If there’s an impact on a design or input data, we can quickly identify the affected simulations,” Neveu explained. “The engineer can then decide whether to rerun the simulation with the existing design or adjust the design first and then redo it. This reproducibility will improve quality because we will always be able to use the right data at the right time.”

Using the 3DEXPERIENCE platform to implement our SPDM solution was a no-brainer. We needed a single source of data that is accessible and shareable, where we can easily find and reuse the information we need.

Shifting to Certification by Analysis

Being able to trace every step is crucial for meeting safety and regulatory standards, giving everyone confidence that simulation results are accurate and reliable. Validated simulations can even be used as evidence for certification, reducing the need for costly physical prototypes and flight tests. Underlying all of this is the Airbus Group principle: “there is no digital certification without digital traceability.”

The approach, called certification by analysis, lets regulators treat simulation results like physical tests once the simulations are proven to be reliable. OEMs like Airbus demonstrate credibility through clear processes, accessible data and full traceability.

On the 3DEXPERIENCE platform, Airbus Helicopters uses a virtual plus real (V+R) test pyramid to progressively validate designs. Here, small component tests are used to validate simulation models and accurately predict real-world behavior. Once these component models are validated, they can be applied to predict how larger assemblies will behave. Each level builds confidence in virtual testing and gradually reduces the need for multiple full-scale prototypes and tests.

“It is imperative for us to be able to organize and track simulations for a given program,” Neveu said. “The 3DEXPERIENCE platform streamlines integration between design and simulation. This ensures traceability that improves collaboration among all simulation fields, whether thermal, aerodynamic, stress analysis, but also between simulation and design or support and service throughout the development cycle. Our ultimate goal is to bring digital continuity to the world of simulation within Airbus Helicopters.”

Enterprise-Wide High Quality Data Management

As Airbus Helicopters continues its digital transformation journey, the company sees enormous potential in making structured design, simulation and manufacturing data more widely available across the enterprise with ENOVIA.

“We have deployed the backbone of SPDM and are integrating our simulation fields into the platform,” Neveu said. “By having all this data stored centrally, we can better exploit it and make it accessible, democratizing it for other fields that may not be familiar with simulation but need the results to guide their own work.”

Airbus is fully committed to modernizing its workflows and has made the 3DEXPERIENCE platform an integral part of daily operations. Teams across the company actively use the platform, exploring its capabilities and applying it to real-world challenges. Their hands-on experience generates valuable insights, which Airbus shares with Dassault Systèmes to directly inform and influence the evolution of future technology solutions.

“There is a good dynamic between us,” Neveu said. “The valuable feedback from our teams helps us improve how we use the platform and strengthens our collaboration with Dassault Systèmes. Through the DDMS program and our strategic partnership, we are developing new features that will help us establish real digital continuity and allow us to fully leverage our data.”

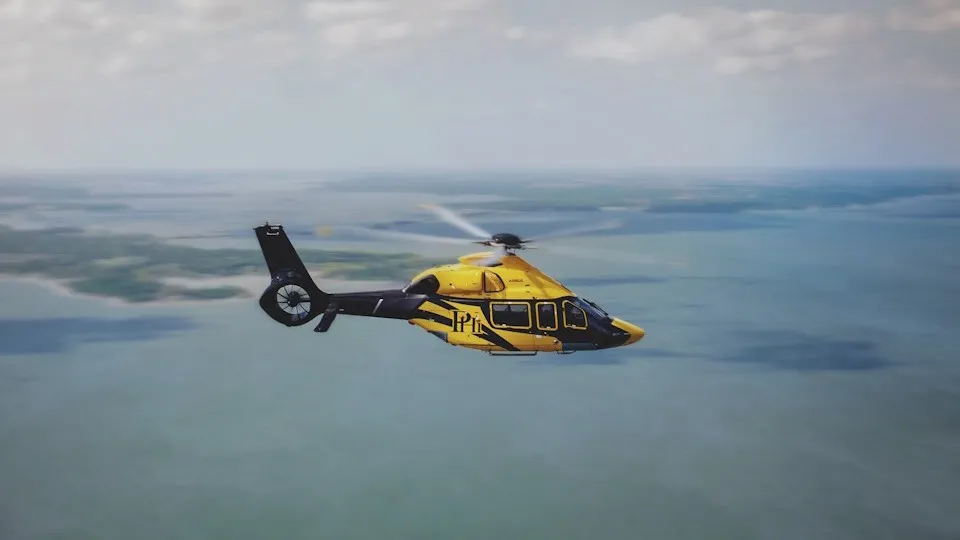

The H160 is designed to excel in every environment—from urban skylines to remote mountain regions—supporting a wide range of missions.

(Photos © AIRBUS)

Discover more about the Cleared to Operate industry solution experience.

Focus on Airbus Helicopters

Airbus is a leader in designing, manufacturing and delivering aerospace products, services and solutions to customers on a worldwide scale. Airbus strives to provide the most efficient helicopter solutions to its customers who serve, protect, save lives and safely carry passengers in demanding environments. Its helicopters are in service across more than 150 countries worldwide, performing nearly every type of vertical flight task imaginable. The company’s product line offers the full spectrum of rotary-wing aircraft solutions for civil, government, military, law enforcement and parapublic uses.

For more information: http://airbus.com/en/products-services/helicopters