Enhance the Structural Integrity of Submarines with a Virtual Twin

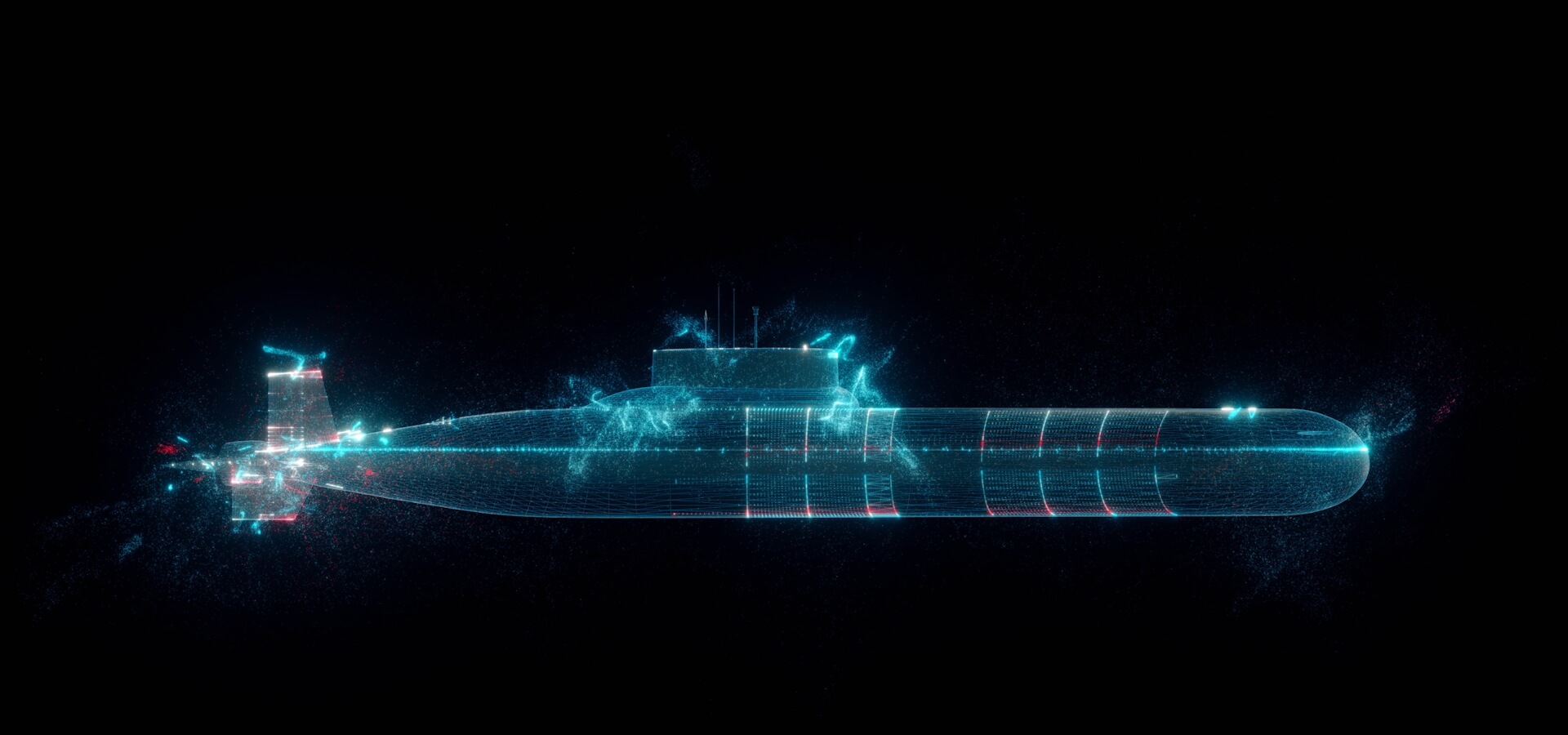

Using the virtual twin experience approach on the 3DEXPERIENCE platform, discover the the applications of structural simulation to submarine engineering.

The deep ocean is one of the most challenging environments known to humanity, and one of the most difficult aspects of surviving underwater is managing water pressure. The pressure hundreds of meters below the surface is measured in megapascals, many tens of times greater than atmospheric pressure. Most submarine vessels are military in nature, and in addition to static pressure, they also must withstand the sudden shockwaves of underwater explosions.

In this article, we demonstrate the applications of structural simulation to submarine engineering, using the virtual twin experience approach on the 3DEXPERIENCE platform from Dassault Systèmes. The virtual twin experience is a complete model of the submarine and its systems that replicates its real-world performance accurately.

Using structural simulation on a virtual twin experience, marine engineers can analyze the structural integrity of the submarine in static conditions, during pressurization and depressurization cycles, or even when exposed to an explosion. Simulation reveals how a submarine will behave in real-world scenarios before prototype testing and sea trials. This reduces the risk of problems being discovered after manufacturing, which would require costly and time-consuming rework.

This article also explains how the power of simulation is enhanced by unified modeling and simulation (MODSIM), and how the SIMULIA Cloud can accelerate design and analysis.

Ensure Static Structural Integrity

Engineers must understand submarine and other marine structures at every stage of development, from the initial concept to the final design. Structural simulation evaluates the stresses and deformations experienced by a submarine during its mission – to be most useful for the designer, this simulation needs to be turned around quickly and flexibly.

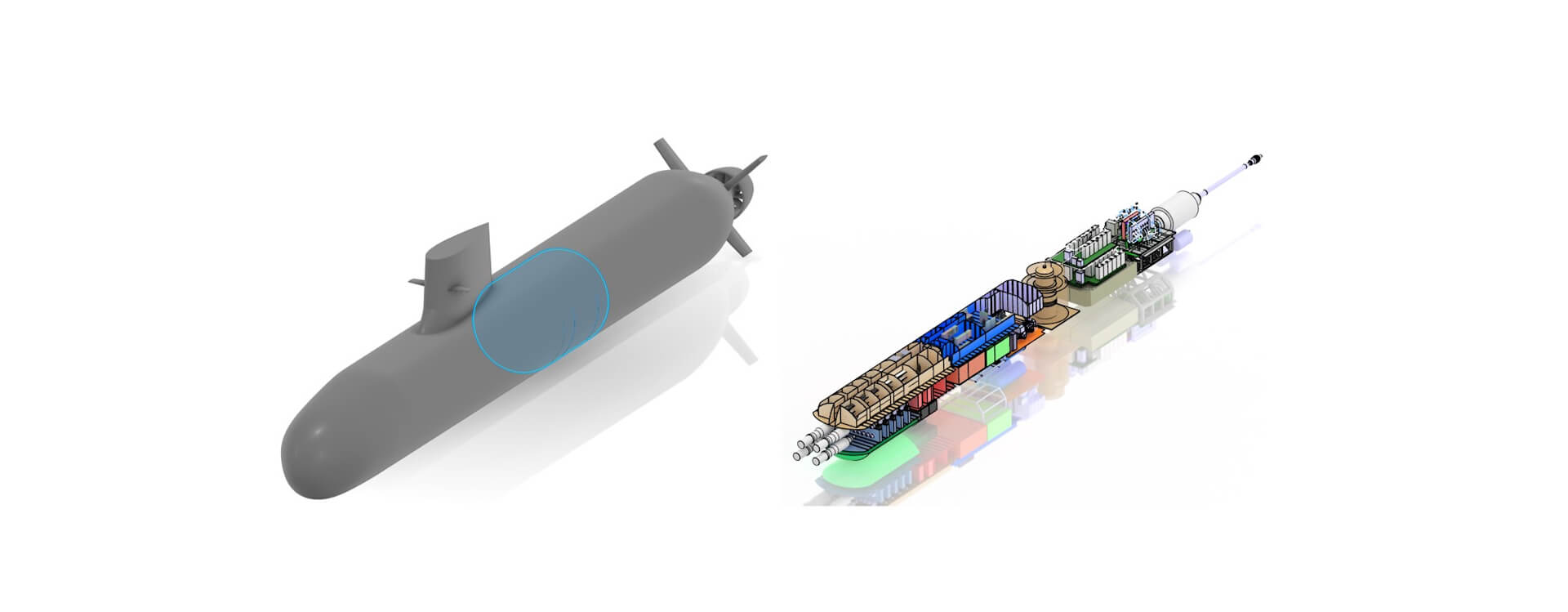

The MODSIM approach means that the geometry from the designer’s CAD tool – for example, CATIA – can be directly transferred to the simulation tool with minimal rework, and a simulation mesh is automatically constructed. The simulation analyst, using the Steel Structures Engineer role on the 3DEXPERIENCE platform, can quickly set up and run the simulation on the Cloud and be confident that the simulation model corresponds to the design. This ensures that the virtual twin experience is a true counterpart to the design and accurately reflects its behavior.

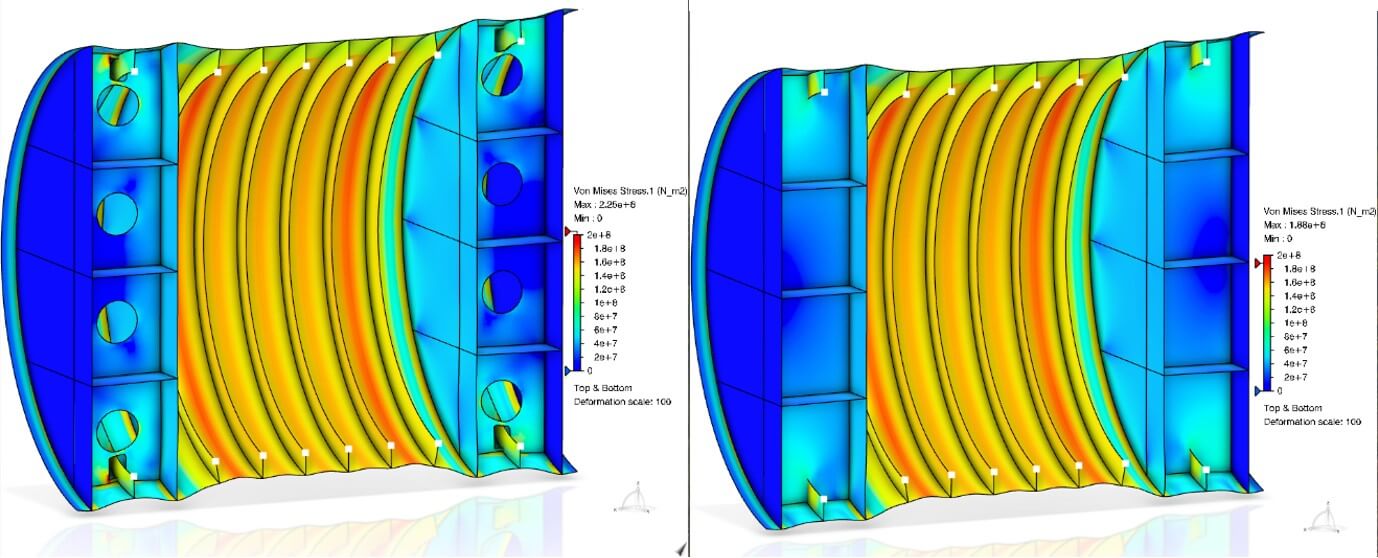

Simulation scenarios that can be studied with Finite Element Analysis (FEA) include static linear or non-linear analyses, buckling, thermal assessments, creep and fatigue. For this particular study, we simulate the structural integrity of an individual macro block within the submarine casing, where all the components are made from high-grade steel. This block is subjected to internal atmospheric pressure as well as external gravity and buoyancy loading for a test depth of 350 meters.

Two simulation meshes were considered: one with a fully detailed mesh across the structure and one using defeaturing to remove some seam details and openings. This significantly reduced the computational complexity of the simulation and therefore, the time taken. However, it also missed some areas of substantial stress where the stiffeners intersect with the bulkheads. This shows the importance of using a detailed virtual twin with a model that accurately represents the real geometry.

Simulate Hull Integrity Over Many Pressurization Cycles

High-profile submarine and submersible disasters in recent years have highlighted the dangers posed by the cyclical pressurization and depressurization of underwater vessels. Every time a submarine submerges, the strain across the structure varies, and over many cycles this can cause fatigue in and around components in the submarine structure. A submarine that initially withstood operating pressures may fail suddenly if a crack forms due to fatigue.

Simulation can model the behavior of a submarine component over hundreds of pressurization cycles. SIMULIA offers fatigue analysis tools that interface with FEA simulation in order to calculate fatigue life and cracking points. Using the Durability Performance Engineer role on the 3DEXPERIENCE platform, this submarine bulkhead was found to be likely to withstand around 700,000 cycles of pressurization and depressurization.

Designing & Engineering Next Generation Naval Defense Platforms

The key challenges for the next generation naval defense platforms are the evolving operational environment and the diversity of threats.

Analyze Underwater Explosion Survivability

Underwater explosion (UNDEX) represents one of the most important and unique challenges to submarines. The physics of an explosion underwater can be quite different to that of one in air, and massive pressure is exerted on nearby objects. Understanding these explosions requires a combination of structural simulation and fluid mechanics.

Acoustic finite element analysis captures fluid mass effects and the incident wave loading on structures interacting with the fluid. The simulation can use total wave or scattered wave formulations: the former combines incident and scattered waves, while the latter concentrates solely on scattered pressure, leveraging the linearity of the acoustic medium. In this instance, we use the total wave formulation and take cavitation into account. The simulation models a TNT charge of 200 kilograms (with a density of 1.5g/cm3) detonated 15 meters from the submarine.

The simulation results are shown below. The formation of the shockwave and subsequent cavitation bubble can be clearly seen over time. The stiffeners demonstrate sufficient structural integrity to protect the submarine (deformation is exaggerated for visibility), but the bulkheads show some lateral deformation. This shows the importance of considering the entire submarine structure when modeling structural integrity.

Conclusion

Underwater environments are particularly challenging due to the tremendous pressures involved. Submarine structures need to be engineered to be able to withstand massive forces over many pressurization cycles, and even underwater explosion.

By using simulation on a virtual twin of the submarine, engineers can analyze submarine structural integrity in real-world conditions before commencing prototyping or sea trials. The virtual twin provides an accurate and realistic representation of the behavior of the submarine itself, with unified modeling and simulation (MODSIM) providing a robust, traceable digital thread between the CAD design data and the simulation model.

By using simulation, submarine engineers can reduce development costs and accelerate design. Issues that are identified can be quickly resolved at their root, reducing the risk of expensive rework later.