Designing & engineering next generation naval defense platforms

The key challenges for the next generation naval defense platforms are the evolving operational environment and the diversity of threats.

The geopolitical tension has led to a new cycle of development for ships with a stronger emphasis on detectability, survivability, perseverance and battle hardening. Naval shipyards are now involved in the development of the next generation naval platforms and their related systems.

Naval ships and submarines become more complex as they must face a very uncertain battlefield environment with more diversified threats (such as drones or cyber-attacks), congested and contested electromagnetic environment with new generations of sonars and radars and more operations diversity (humanitarian, asymmetric and conventional warfare). Adaptability to different mission profiles and upgradability by design as well as increased operational availability of naval assets are key demands from the operators.

To develop the next-generation naval platforms and their related systems, shipyards must tightly connect and synchronize a variety of engineering disciplines to find the optimum solutions and ensure that everything fits and work properly in a confined environment.

A flawless execution is necessary to meet the project requirement including good planning, perfect coordination and accurate information. By connecting the various department and disciplines around the virtual twin of the ships, shipbuilders ensure to meet technical requirements, schedules and budget. These are the main objectives of having a single source of truth with digital continuity and model-based engineering in shipbuilding.

Moving towards Model-Based acquisition

Addressing these challenges require a transformation in the acquisition process, with new and collaborative ways of working between defense agencies and their suppliers. Traditional document-centric approaches are moving in favor of connected and trusted models, providing a digital or Virtual Twin, an executable virtual representation of a physical system of systems that delivers unique capabilities. Many defense organizations are already adopting these principles and moving towards Model-Based acquisition. The upstream extension of MBSE (Model-Based Systems Engineering) is also an attractive value for shipyards to validate their concept and - thanks to CATIA - the concept and design of their systems avoids the most costly errors. To achieve this transformation and connect the dots between delivery partners, a collaborative platform is required.

In this ebook, go through the 4 key challenges in delivering such a successful program:

Integrating innovation

Bringing together expertise and enabling them to work as one enterprise

Optimizing capability

Once connected affording them the ability to decide on the best solution

Improving outcomes

Using the same connectivity to manage the complexity of execution

Maintaining capability

How to upgrade through-life maintaining a dominant capability

Model-Based acquisition and support

Digital enterprise enabling affordable and dominant naval defence capability.

Boost performance and innovation

Requirement management can also benefit from the model-based approach by running early simulation and forecast the platform performances to better define the project specifications. It gives the ability to manage requirement specifications and their evolution effectively with full traceability throughout an asset entire lifecycle and efficiently monitor the progress on different activities. By applying simulation to the earliest phase of design, it is possible to accurately predict, compare and simulate naval platforms behaviors to shorten the development cycles by minimizing extensive physical prototyping and testing.

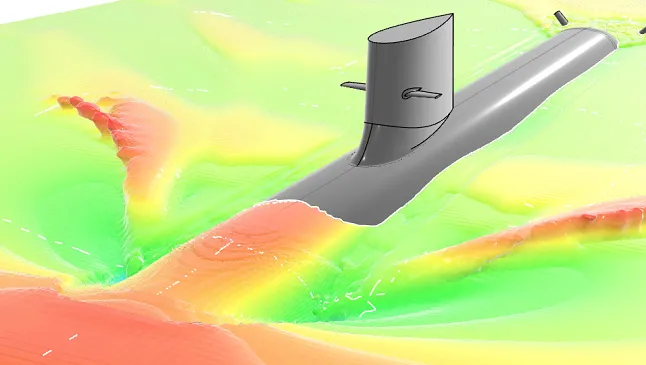

Designing a stealthier submarine with design-driven simulation tools

Submarine engineering is a challenge - there are few areas of engineering that require such precise control of as many different domains of physics. Discover how united modeling and simulation enables the development of modern Undersea Defense Technology, using stealth design as an example of the benefits of a MODSIM approach.

Improve work collaboration with one single source of truth

With the 3DEXPERIENCE Platform, shipyards can adopt a Model-Based approach to define the system architecture of the concept and to dimension the different onboard systems, using communities and conversations to share and innovate throughout the internal groups or entire ecosystem.

Using the 3DEXPERIENCE Platform, capture and manage customer requirements and industry regulations to ultimately ensure that the final asset be built to specification. Finally, they can transform their initial concept ideas in complete virtual twin of the ships for engineering and production validation. Coordinate collaboration with the Virtual Twin.

One unified Environment

The 3DEXPERIENCE platform provides a unified environment to imagine, create and deliver the next generation of products, services and experiences. It brings together multi-disciplinary teams and enables the continuity essential to develop complex and connected products faster. It acts as the single version of the truth required to transform ideas into innovative products and experiences.