Industrial Engineering: Resource Planning

Define and simulate the plant layout, flow, assets and resources needed to produce products efficiently and in a safe environment.

Using 3D virtual twin experience technology, rapidly validate normal production change requests, new product introductions, or quickly pivot operations to alternative products as the result of disruptive events.

Resource Planning in action

- Virtual Commissioning

- Simulate Machines and Ergonomics

- Simulate Factory Flow

- Define Plant Layout

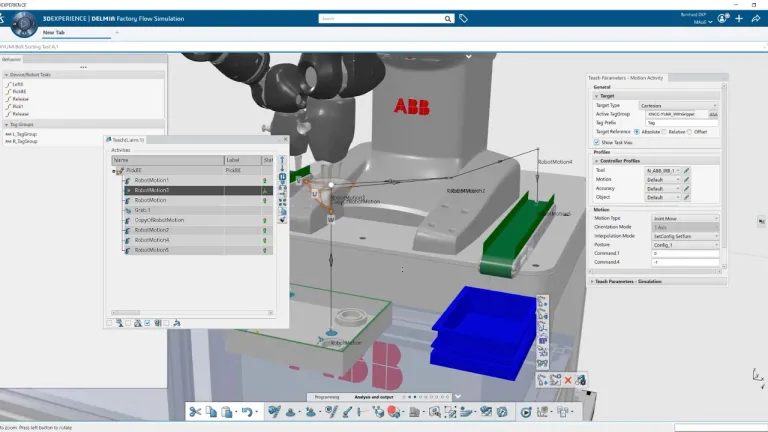

Virtual Commissioning

Robots and machines are tested virtually before sending them to real machines.

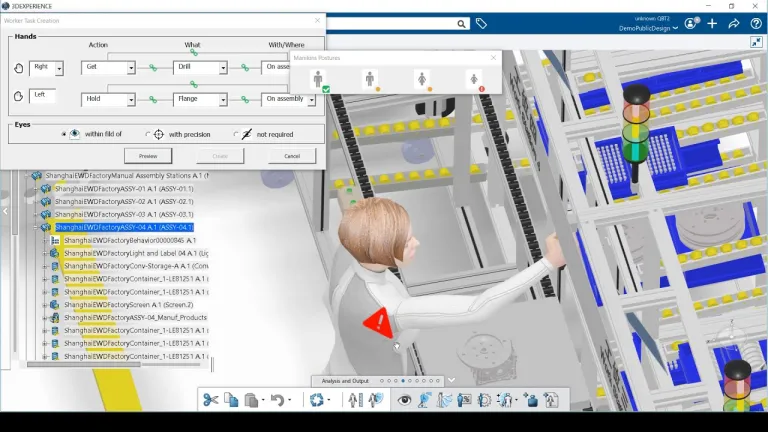

Simulate Machines and Ergonomics

As the factory flow is modeled, machines and the ergonomics that are associated with the line are simulated

Simulate Factory Flow

Once the production line is created in a virtual model, the flow of products can be simulated and the flow of work in those production lines, to have validation of manufacturing process plans.

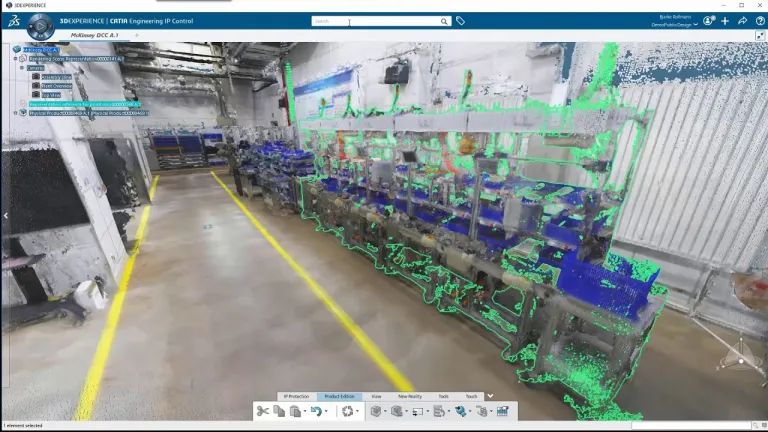

Define Plant Layout

Manage a full plant Layout in 3D including the ability to position and manipulate resources. With layout data accessible throughout the extended enterprise, it means that intellectual property can be leveraged.

Resources

Contact our sales team

Are you ready to take the next step in your Factory of the Future journey? We can help! Fill in the form to have a Dassault Systèmes Manufacturing expert contact you. Include questions and topics you would like to discuss to tailor the call to your needs.

Next: 02 Industrial Engineering: Manufacturing Planning

Enrich the product and resource definition; define and validate a process plan and create work instructions to meet production goals. Digital visualization of resource and process changes help accelerate time-to-production in any scenario, from any location, leveraging the cloud.