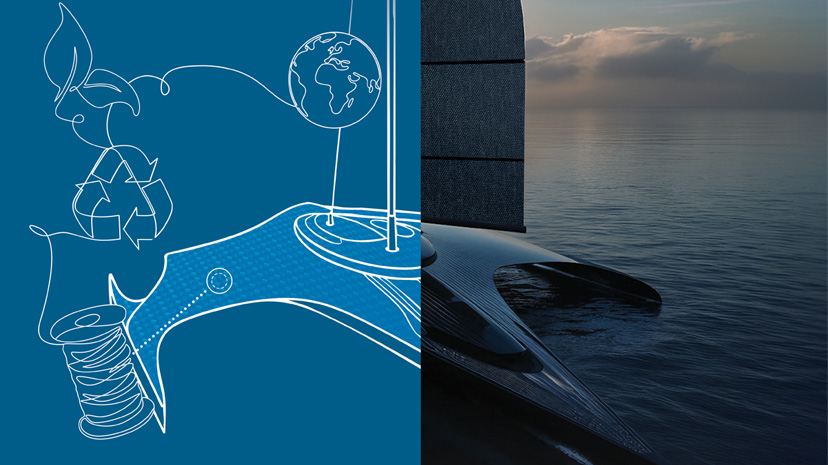

CGreen Bio-based Carbon Fiber

IF WE produce a local sustainable carbon fiber, CAN WE reduce the composite CO₂ carbon footprint and ensure EU’s sovereignty?

Challenge

Carbon fiber is a strategic material used across transportation, energy, and manufacturing for its strength and lightness. But today, it is entirely derived from petroleum and mainly produced outside Europe. This creates both environmental and sovereignty challenges, as demand is projected to exceed global production capacity by 2028 and prices continue to rise.

CGreen was founded to address this dual challenge: reducing the environmental footprint of carbon fiber while securing European independence in its production. By developing a sustainable, bio-based alternative made from recycled cellulose, CGreen combines innovation, circularity, and sovereignty to meet growing industrial needs responsibly.

Disruptive Innovation

The disruptive idea of CGreen is the creation of a carbon fiber made from cellulose (silos), sourced from recycled paper or recycled cotton, instead of petroleum-based materials.

Cellulose is the most abundant material on Earth, and their unique spinning and carbonization processes (entirely developed in-house) make it possible to significantly reduce the CO2 impact.

This innovation provides a sustainable alternative to petrol-based carbon fibers and a local, bio-based sourcing solution.

Impact

CGreen contributes to climate action (SDG13) by reducing the environmental impact of carbon composites and promotes responsible consumption (SDG 12) through local bio-based sourcing.

Using CGreen carbon fiber instead of petroleum-based carbon fiber will save the CO2 equivalent of:

- 110 round trips Paris–New York during the first three years,

- 164 cargo trips across the Atlantic per year from 2032.

The project also helps secure supplies and prices while strengthening European sovereignty in industry and innovation (SDG 9). By creating jobs in France, it supports economic growth (SDG 8), and with two women co-founders, it advances gender equality (SDG 5). Finally, its strong partnerships highlight the importance of collaboration for sustainability (SDG 17).

Leveraging the 3DEXPERIENCE Platform

CGreen considers the 3DEXPERIENCE platform a “fantastic opportunity” to better understand their materials, scale up processes, design, manage, and maintain their operations.

They plan to use several key components:

- CATIA: To design equipment, analyze their metaphysical approach, and improve life cycle assessment.

- BIOVIA: To understand molecular interactions and solvent-solvent impact, crucial for spinning.

- SIMULIA: To simulate carbonization and full composite structures.

- DELMIA: To optimize industrialization, scale-up, material flow, and logistics.

- ENOVIA: To manage their product life cycle and database

Collaborative & Collective Intelligence

CGreen benefits from a strong scientific partnerships and institutional sponsors, reflecting the use of collaborative intelligence through external expertise and support. But also from the founding team, Gaëlle Guyader and Céline Largeau, both engineers with 10+ years in the automotive industry, who lead the R&D project at the origin of the startup.This foundation demonstrates a reliance on shared expertise, external knowledge, and collective collaboration to advance their innovation.

CGreen

CGreen pioneers sustainable carbon fiber made from recycled cellulose sourced from paper or cotton. Its process cuts CO₂ impact by threefold, boosts Europe’s material sovereignty, and redefines composites with eco-efficient, high-performance fiber.

Meet the Team

Explore Our Portfolio

Submit Your Application

Interested? Take your chance to elevate your project to the next level.