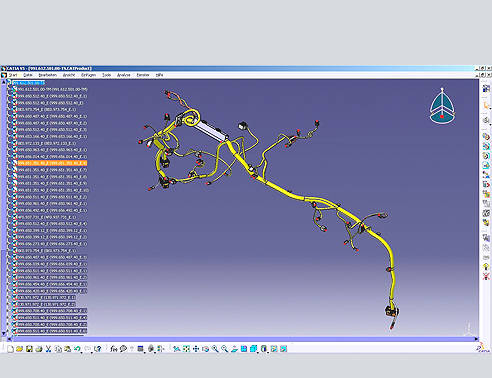

V5Harness 2D Suite

V5H (integrated in CATIA V5) offers functionality for design engineering, drawing generation and manufacturing documentation. Data consistency in the whole...

A solution by: SMARTCABLE

Application domain: Equipement & Systems Engineering

Solution Overview

V5H (integrated in CATIA V5) offers functionality for design engineering, drawing generation and manufacturing documentation. Data consistency in the whole design process and synchronization between the 3D model and created documentation is guaranteed.

- V5H BASE merges geometric information from the CATIA 3D model, electrical information (several interfaces are available) and configuration, and it creates a digital master model. Consistency and rule conformity of data are validated. V5H CONF allows the creation of any customer-specific configuration based on the master model. V5H CONF enables handling of geometric and electrical variants. V5H CALC simulates work planning. The production cost (material + manufacturing time) for each customer configuration can be calculated. V5H CHANGE guarantees complete and reliable change management throughout the product development process. It assures reliability and traceability. A reduction in processing time by up to 80% can be achieved.

Benefits

- Continuous data flow from design to manufacturing Embedded design knowledge to avoid design errors and reduce manual processing time Reduction of manual steps, of errors, and of time for harness creation and change process Simulation of manufacturing process, precise preview of production cost