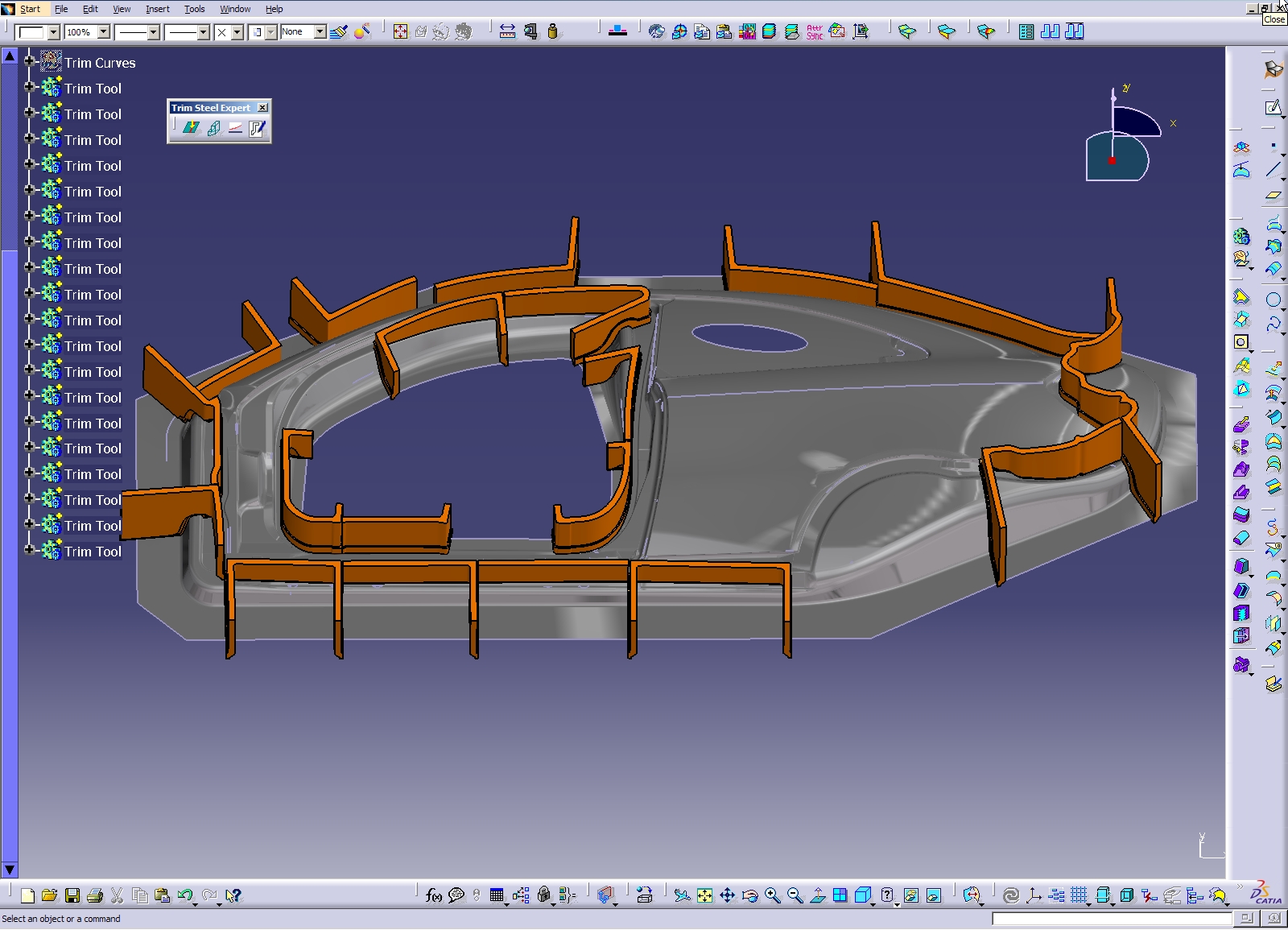

FASTTRIMSTEEL

A solution by: CENIT

Application domain: Mechanical Design

Solution Overview

Product Overview

FASTTRIMSTEEL is a completely integrated CATIA V5 solution to automate the design of trimming tools used in the sheet metal and plastics die forming industry. The solution creates the stock material (casting) and the tool surfaces as separate elements to fully support the engineering and manufacturing process. It furthermore will embed the specific parameters as known in the tool engineering industry. Trimming process parameters will be taken into account. Typical parameters such as shear and back spacing. Collision checks will ensure the trimming tool to actually cut the material instead of touching the material at undesirable places, causing material deformations or bad cutting operations.

Product advantages:

- Generation of the base geometry (cast body or stock material), the NC-prepared surfaces of the knife head and the final trimming tool body.

- Library of knife cross sections

- Definition of cast oversize dimensions

- Definition of trimming process parameters (intrusion and shear)

- Collision control

Benefits

- Dedicated solution for trim steel design with industry specific definitions and parameters

- Complete parameterization of the trim steels; all entries can be modified at any time.

- Evident time savings at trim steel design

- Uniform design process for all engineers

- Data consistency from design to manufacturing

- Associative and update compatible

- Process planner and tool engineer are involved in concurrent engineering process at an earlier stage.

- Seamlessly integrated into the CATIA V5 workflow, based on the CAA V5 architecture, operated with ease-of-use interfaces