FAST4AXES

A solution by: CENIT

Application domain: Manufacturing

Solution Overview

FAST4AXES

Software to Program and Simulate Wire EDM

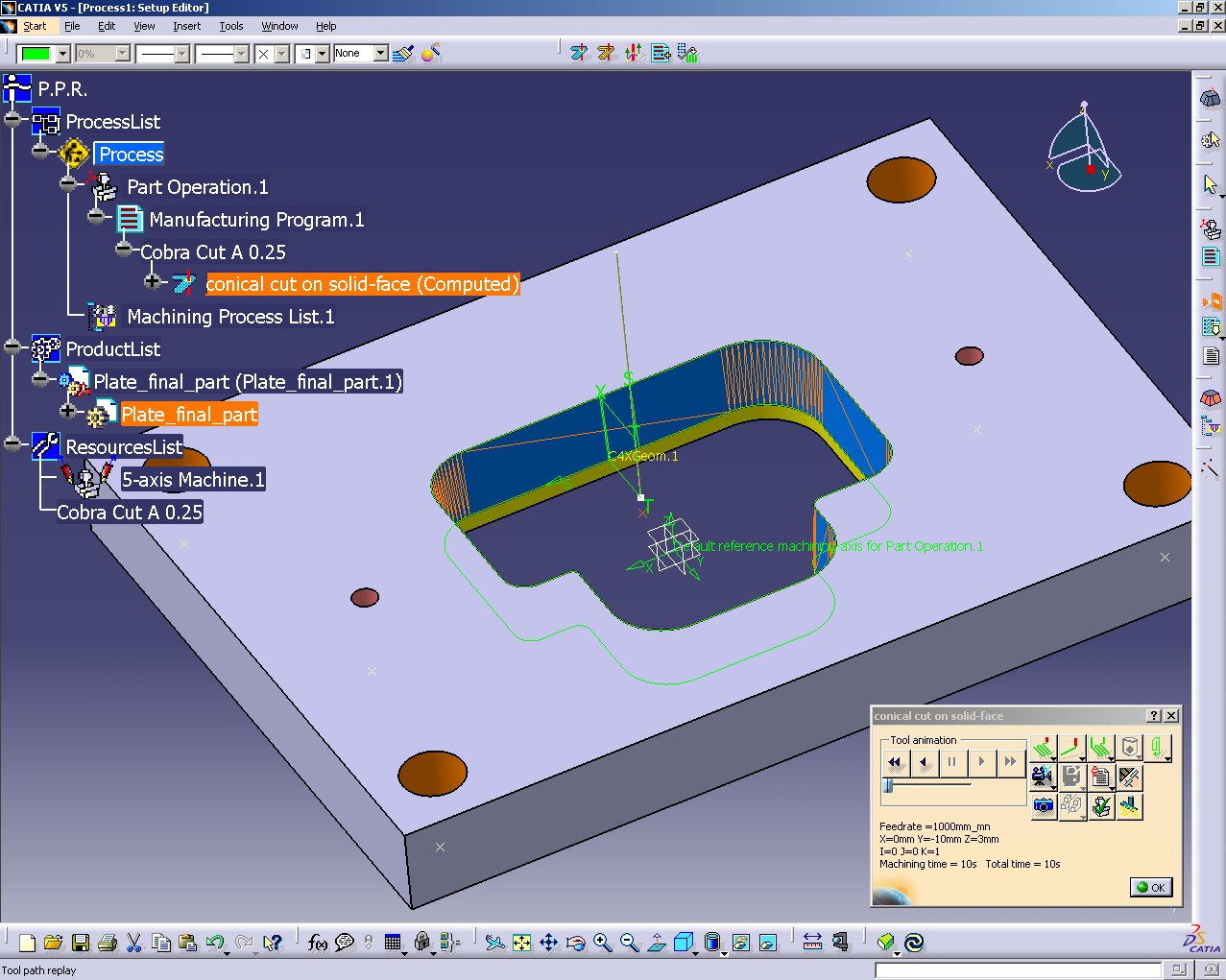

CENIT FAST4AXES allows NC users to benefit from advanced and easy-to-use Wire EDM manufacturing techniques. It provides a full set of pre-defined and re-usable machining strategies for 2 up to 4 axis Wire EDM machining. The software offers the user all the core functionalities of a NC system shared within CATIA V5 NC Manufacturing solutions: integrated tool path simulation , set-up and NC programs definition. It also provides integrated and dedicated post-processing facilities and also many Wire EDM strategies , such as: powerful contouring machining including drive curve interpolation into tangential arcs and lines, destruction cut operation (pocketing). Variable technological events can be set. 4-Axis machining includes synchronization of points as milestones and precise offset computation facilities. A very easy-to-use interface allows the user to benefit from Wire EDM techniques in a perfect interoperable way with all CATIA V5 NC Manufacturing solutions.

FAST4AXES - Functional Advantages

- Programming of 3D contours. Upper and lower contours with milestones and direct programming of ruled surfaces and solids.

- Support of geometrical features.

- Integration of machine tool specific technologies is optimal by powerful standard post-processors

- Available for Agie, Charmilles, Fanuc, Mitsubishi, Sodik...

- Adaptable on-site by PP generator software FASTPOST

- Machining Operations: contouring/pocketing/point strategies...

- VisualBasic support to create flexible machining strategies

- Direct simulation of each operation

Benefits

- Combines dedicated functions and ease-of-use of stand-alone programming tools with the benefits of an integrated CAM software with respect to an optimum geometry support and associativity to design changes.

- Identical user interface and infrastructure to V5 NC products like PMG, Programming of all CATIA elements (sketches, solids, upper/lower contour.)

- Integration of machine tool specific technologies is optimal by powerful standard post-processors.

- Automation by programming of knowledge-based scripts

- Low prerequisites to allow a CATIA based stand-alone system for wire cutting