3DCS Variation Analyst for 3DEXPERIENCE

V6 has revolutionized CAD. With it, come powerful new features and the 3DExperience, allowing collaboration and innovation like never before. Having...

A solution by: DIMENSIONAL CONTROL SYSTEMS

Application domain: Mechanical Design

Solution Overview

V6 has revolutionized CAD. With it, come powerful new features and the 3DExperience, allowing collaboration and innovation like never before.

Having been a Gold Level Software Partner with Dassault Systemes in their CATIA V5 software for more than ten years, DCS has the experience and expertise to develop new tools for CATIA products. As a result, 3DCS is now fully integrated into the 3DExperience and CATIA V6!

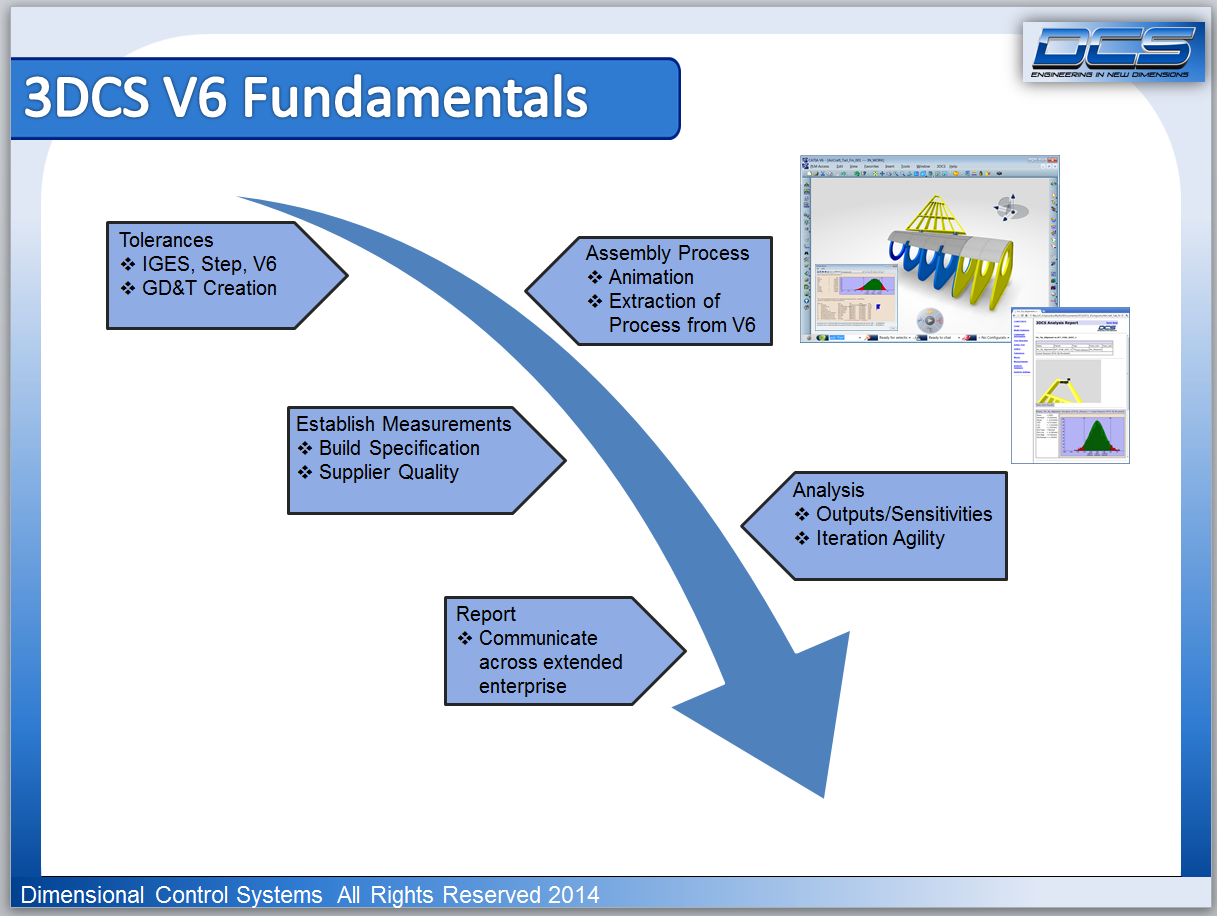

With 3DCS for V6, engineers can test manufacturing like never before utilizing CATIA V6's powerful features.

Create photo realistic tolerance, gap and flush studies, simulate assembly and analyze the design for fit and function, or teststrategies and processes like welding, clamping and thermal displacement.

All of this without leaving the 3DExperience. Collaborate, innovate and improve your designs with 3DCS for V6.

Benefits

Optimize Product Designs and Processes

3DCS V6 allows CATIA users the ability to evaluate design and assembly concepts up front, where problems can be identified early in the product development lifecycle. Optimizing for dimensional integrity improves the robustness of your design and process by maximizing part tolerances while maintaining the dimensional requirements of your final assembly.

Reduce Cycle Time and Rework Costs

Shorten development time, accelerate time to market, and reduce costs by utilizing the capabilities of 3DCS V6 for virtual prototyping.

Identify Key Contributors

Identify the source of variation and determine key characteristics in your design. By maximizing part tolerances while controlling dimensional requirements, manufacturing costs can be reduced with less rework to tools and gages, minimized scrap and reduced warranty defects. 3DCS CAA V5 Based helps your bottom line and significantly improves product quality by validating that parts fit and function together before design release and throughout production.