Mitigate Supply Chain Risks with End-to-End Visibility

Recent disruptions served as a warning of what happens when manufacturers have a fragmented view of their supply chain. Here we discuss how resiliency starts with a control tower view.

In 2020, manufacturers without end-to-end visibility were in trouble. Their supply chains were battered by an unprecedented range of disruptions brought on by a global pandemic. Factories and borders were closed. Components were in short supply and companies struggled to keep operations going without putting their workers’ lives at risk. Few industries and fewer global supply chains were unaffected.

“One thing a lot of industries realized was that they didn’t have a control tower view of their operations,” explained Adrian Wood, DELMIA Strategic Business Development Director at Dassault Systèmes. “Their operations were broken into silos, so no one could identify the full impact of the pandemic and its larger scale disruptions on their end-to-end supply chain.”

The Dangers of Driving in the Dark

How useful would your GPS be if it knew your destination but not where you are right now? What if it only saw some of the available roads and no repair works at all? What if it could only roughly estimate distances?

Such a device would do a poor job of solving the problems you already have. More likely, it would add to your difficulties.

Now, on top of that, imagine that the dashboard of your vehicle is dark. You can’t see whether the tank is full or empty, whether the battery is in good health, or whether anything else is at the point of failure.

Finally, imagine that it is not just you, but multiple players who must reach the same destination - and everyone has their own idea of what that destination is.

If you don’t have real-time visibility into the state of your operations, company and industry, you are not developing a plan from a strong foundation. If you set a plan for tomorrow without knowing where you are today, you will introduce risk.

How to Get a Control Tower View of Your Operations, Company and Industry

Discover how to gain supply chain visibility and control to manage vulnerabilities for lower impact of future disruptions.

Looking at Supply Chains with New Eyes

Major disruptions are very good at highlighting blind spots in supply chains, and the Covid-19 crisis compelled leaders to take a closer look at their priorities. A recent study by IDC revealed that globally, improving resiliency was a key motivator for current and future supply chain changes. A good number of these resilience-building changes will be driven by technology. As one 2020 survey found, 75% of executives saw new urgency in pushing forward with digital transformation.

Tools and Capabilities That Enhance Supply Chain Visibility

- Data Centralization

- Shared Platform

- Virtual Simulation

- Machine Learning

Data Centralization

As we have seen, before you can confidently decide where you’re going, you need to know where you are. In manufacturing, this means that data from numerous internal and external sources must be gathered, aligned, enriched, and updated in real time to provide all stakeholders with a single source of truth. This gives a unified view of every process and operation along the supply chain.

Virtual Simulation

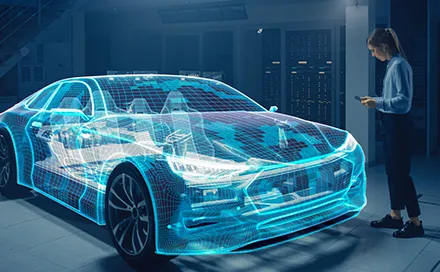

A virtual twin of your supply network provides an accurate and detailed end-to-end model of your entire operations. Updated in real time, the virtual twin changes to continuously mirror your actual network. This enables you not only to see things as they are, but also to test and optimize scenarios, measure impacts, and choose the best, most informed course of action for any situation.

Machine Learning

A cloud-based platform that comes pre-packaged with machine learning algorithms sifts intelligently through past and present data. Without requiring human intervention, it alerts you to any real or potential issues and shines a spotlight on opportunities hidden within your supply network.

Looking to the Future

At a time when inherent supply chain manufacturing risks are compounded by unprecedented disruptions, end-to-end visibility is more important than ever. It is the foundation of the agility you need to pivot with new circumstances, whatever these may be.

Read our top articles on Operational Optimization

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives