Turn Industry 4.0 Data into Insights for Successful Mass Customization

With the right platform, manufacturers can leverage data from Industry 4.0's connected ecosystems to become full-fledged product configurators and realize the benefits of mass customization.

The Challenging Era of Mass Customization

The era of mass customization is here, driven by customers who not only expect personalized products and experiences but are significantly more loyal to manufacturers that provide them. However, many manufacturers face the challenge of mass customization. They are still tied to legacy manufacturing systems and processes that lack the agility and connectivity of a modern, data-driven approach to tackle mass customization complexity.

Industry 4.0 and its innovations hold the solution. They connect valuable ecosystems for seamless collaboration across the value chain, allowing manufacturers to accelerate better mass customization results.

Data-Driven Strategy for Answering Customer Demands

Digitalization offers insights to address customer needs through mass customization. Learn more.

Massive Potential in Mass Customization

Becoming full-fledged product configurators requires manufacturers to first transform connected ecosystems’ wealth of data into actionable insights. These data-driven insights allow them to form closer relationships with customers, continuously improve processes and build agility.

“To unlock the full potential of mass customization, manufacturers need to deliver the right information at the right time from a common data model to the value chain contributors on a real-time basis,” said Fred Thomas, DELMIA Strategic Business Development and Marketing Director at Dassault Systèmes.

This is possible with a digitalization strategy that’s platform-centric. Only then can manufacturers derive significant value from their connected data and benefit in these game-changing ways:

- Authentic Insights

- Continuous Iteration

- Increased Agility

- Improved Productivity

Authentic Insights

In a connected production, customers gain the ability to co-create with manufacturers on products that answer and meet real market needs. More than that, the data flow of customer preferences helps manufacturers generate more accurate customer profiles, which in turn helps them better predict and deliver products that win customer loyalty.

Continuous Iteration

The data doesn’t stop after the product has left the factory. Some of the most valuable data come from how customers use the product and how the experience can be better. This behavioral data enables manufacturers to continuously improve their product offerings and, subsequently, optimize their operations to remain competitive in the market.

Increased Agility

A connected ecosystem offers end-to-end visibility and real-time information sharing for manufacturers to adapt quickly to evolving customer behavior and preferences. By including customer learnings early in the process of mass customization, manufacturers can reduce risks and avoid costly missteps of investing heavily in products that lack market demand.

Improved Productivity

Data insights shared across the value chain help manufacturers deliver the right product on time without overstocking inventory while reducing manufacturing waste. The data stream facilitates manufacturers to make informed decisions for productivity and cost containment improvements in key areas such as procurement, inventory management and transportation.

The Digital Thread That Connects

A lot of big data analytics solutions in the market provide good tools to analyze transactional data. But when it comes to mass customization, the data is not linear. It’s not just rows in a simple table. So performing big data analytics becomes much more complex.

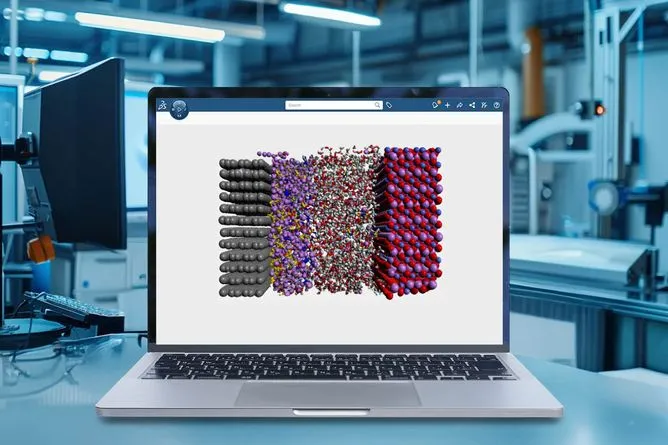

To deliver customized product offerings at scale, manufacturers need to turn to the 3DEXPERIENCE platform. It provides a digital thread from product design to distribution, integrating people and information in the manufacturer’s organization and value chain. It allows manufacturers to collect, analyze and transform data from Industry 4.0’s connected ecosystems into insights for continuous improvement of products and operations.

The platform powers a closed-loop environment to simulate processes, enabling manufacturers to respond quickly to market demand shifts and order patterns while minimizing risks. Performance metrics from manufacturing operations can be looped back to a virtual twin of the factory for analysis based on the aggregated information from each plant.

“Dassault Systèmes has taken the Industry 4.0 concept to the next level with the 3DEXPERIENCE platform that provides a connected, smart manufacturing experience for all stakeholders. Our platform delivers a real-time and data-driven approach to rapidly adapt to the peaks and troughs of day-to-day operations, especially changing customer demands. The result is optimized operations and agile delivery of products that always align to customer preferences,” Fred concluded.

Read more articles on Connected Industry

Explore our Industry Solution Experiences

Learn more about how our industry solutions can help you to achieve your professional ambition and business objectives

6 Steps to Smart, Efficient Tires

Ready to unlock speed and precision in tire development? Here’s how to achieve it with our integrated platform.

- Accelerate Materials Innovation

- Model and Simulate From the Start

- Maximize Production Efficiency

- Foster End-To-End Collaboration

- Ensure Digital Continuity

- Embrace Sustainability

80% of tire innovation stems from materials. Predict and optimize existing tire formulations through platform-driven simulation and collaborative material management to develop new, sustainable materials quickly and precisely.

Shorten design cycles by integrating multiple design factors into virtual prototypes from the start. Optimize the ‘Magic Triangle’ and reduce the need for check tires by up to 85% through modeling and simulation.

Streamline operations to improve plant availability and boost productivity. Integrate 3D design and simulation to optimize processes — reducing development and testing time by up to 25%.

Incorporate data from all stakeholders for a seamless and integrated tire development process. Real-time collaboration improves communication, reduces supply chain disruptions and optimizes manufacturing operations.

End-to-end digital continuity shortens the testing and evaluation process from weeks to hours. This single source of truth boosts right-first-time rates, speeds up time to market and aligns every development phase to business objectives and customer demands.

Embed sustainable practices throughout the tire development lifecycle. Optimize resource and energy use, minimize waste and reduce greenhouse gas emissions to meet regulatory standards for a sustainable future in tire development.