WSAudiology

WSAudiology (WSA) is one of the world's largest manufacturers of hearing instruments. Their highly advanced audiology technology is compact, reliable, and affordable. WSA uses SIMULIA's CST Studio Suite to optimize designs to the limits of physics. Faster and more precise simulations help WSA speed up product development cycles and allow them to maximize innovation.

WSAUDIOLOGY DEVELOPS LEADING-EDGE HEARING AIDS WITH SIMULIA SIMULATION

In the early days of hearing care, hearing aids were basically sound amplifiers with few features and very limited means for adjustment to individual hearing loss. While those devices back then could restore some degree of audibility and speech understanding, sound quality was poor and sound artifacts, such as whistling or clicks, were common. However, the significant demand for hearing aids warranted considerable corporate investment through the years into the research and development of hearing aid technologies.

Over five percent of the world’s population—430 million people—require rehabilitation to address their disabling hearing loss. The World Health Organization estimates that by 2050 over 700 million people—or one in every ten people—will have disabling hearing loss. [Disabling hearing loss is greater than 35 decibels, as defined by the World Health Organization.] Over 1 billion young adults are at risk of permanent, avoidable hearing loss due to unsafe listening practices.

Concern is growing about the rising exposure to loud sounds in recreational settings such as nightclubs, discotheques, pubs, bars, cinemas, concerts, sporting events and even fitness classes. With the popularization of technology, devices such as music players are often listened to at unsafe volumes and for prolonged periods of time. Regular participation in such activities poses a serious threat of irreversible hearing loss.

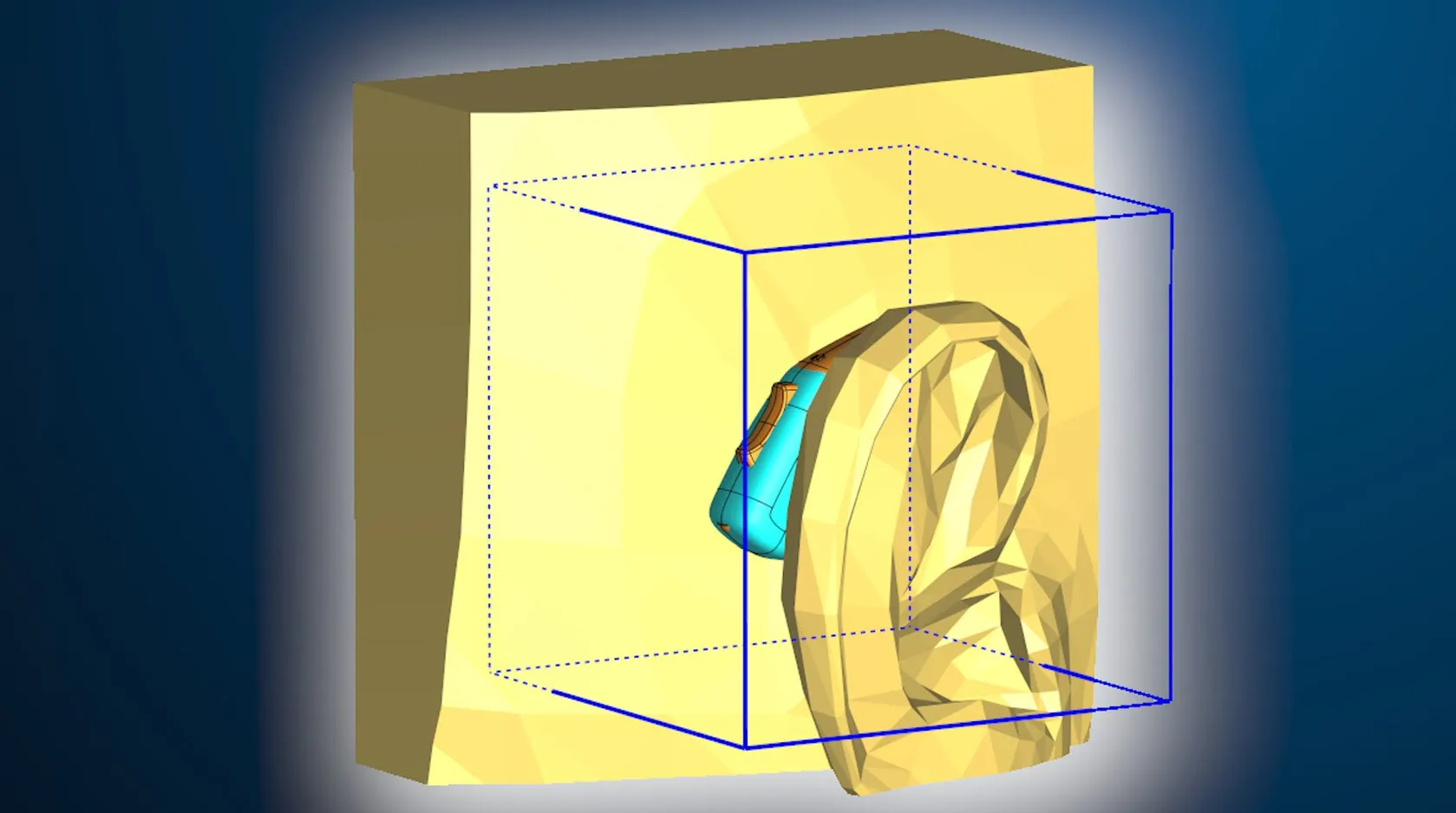

WSAudiology (WSA) is one of the world’s largest manufacturers of hearing instruments. Comprised of multiple brands, WSA has a mission to bring back wonderful sound to millions of people worldwide with small, technology-rich devices. While most technology innovations are proudly displayed and trumpeted among consumers, such as smartphones, electric cars, wearables, or home devices, hearing aids tend to be a source of embarrassment, making hearing aid design critical to success. WSA’s Signia Active Pro is one solution that is designed to look like an earbud instead of a hearing aid in an effort to relieve some of the stigma around hearing loss.

“We try to make our hearing aids as small as possible,” says WSA Chief R&D Officer Stefan Menzl. “Some of them are completely invisible. We try to hide them behind the ear or in the ear, so people don’t see them.” Hearing aids are highly complex devices that must meet a wide variety of needs in a highly competitive global market. WSA leverages state-of-the-art technologies and laboratories to meet the demands of hearing aid users worldwide.

BUILDING PRODUCTS THAT INTERACT WITH INVISIBLE FORCES

Hearing is essentially transforming sound vibrations from the air into nerve impulses going to the brain. The brain interprets these impulses as sound and does the whole process of selecting the right sound and suppressing any kind of interference. Hearing Impairment is not only affecting the transformation itself but also the suppression capability of the brain.

This leads to significant design challenges for hearing aid manufacturers. “We try to make louder what needs to be louder, but not to amplify sounds that do not need to be loud,” says Menzl. Think of dining in a restaurant where all kinds of conversations and random noises abound.

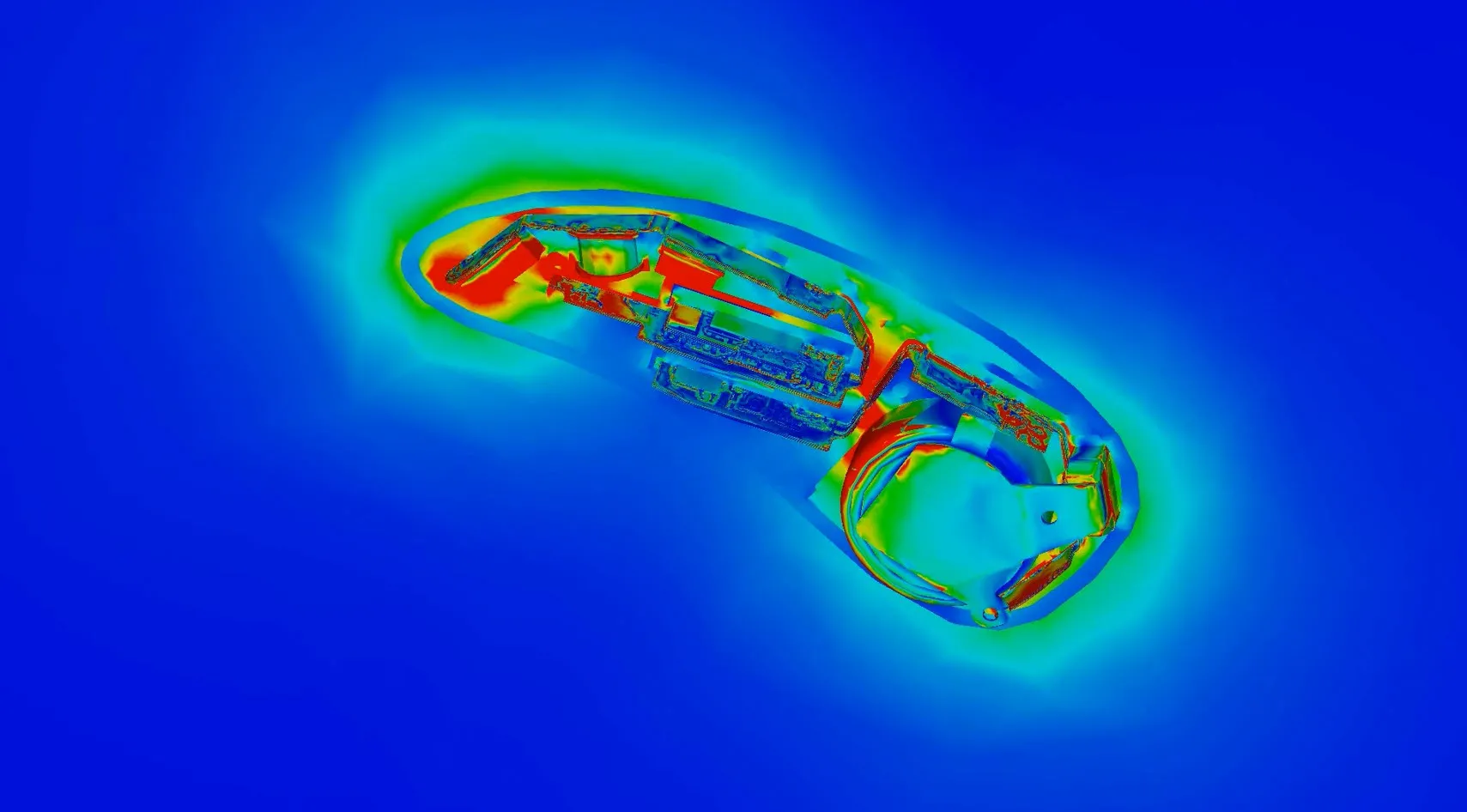

Hearing aid design also needs to consider unwanted electromagnetic waves that could introduce unwanted sound interference. For example, in the old days, a mobile phone next to your car radio would make a noise like dit-dit-dit-dit. “That’s one of the beauties of the simulation work we do,” continues Menzl. “We know whether a device works before we have completed the design, and that’s super important for us.”

Being able to digitally test the invisible physics that affect hearing aid devices using SIMULIA’s CST Studio Suite saves WSA time and money. “If you need to try everything in the real world, it will take forever before you develop something as complex as a small hearing aid. The better approach is that you try a lot of things in a simulation,” says Menzl. Different shapes of printed circuit boards (PCBs), different shapes of hearing aids, and different inlets for microphones all affect hearing aid design and performance. Because simulation and optimization are integral parts of its design process, WSA can confidently produce the final product. “That’s how we achieve our short development times,” states Menzl.

Moreover, invisible electromagnetic waves are also used for wireless communication. Hearing Aids are not only creating a wireless connection to exchange control and audio data among themselves but also Bluetooth technology is used nowadays to connect to the outer world. This type of radio frequency technology allows wireless audio streaming from a smartphone, tablet, or TV Streamer directly into hearing aids without using various accessories to facilitate the audio stream. This high-quality direct audio stream into both ears is hugely convenient and popular among hearing aid users. “The only way you can really predict how an antenna works is by simulation,” says WSA Head of Wireless Systems Thomas Fischer. “[Hearing aid] antennas are really cutting-edge technology–close to the head, close to the ear, and within a very tiny hearing aid.”

SIMULIA’s tools test hearing aid design in several scenarios, including PCB simulation, electromagnetic simulations with various material types, and even drop testing. “An important feature of our product is that you can drop it all the way from the ear to a hard concrete floor,” says Menzl. This simulation is essential because failures are common in drop testing. Only after all these tests (and more) are conducted digitally within SIMULIA and the appropriate design modifications are implemented and finalized does the product progress to physical testing in a lab.

High-quality sound can be elusive. “We do comprehensive simulations in terms of signal processing,” says Fischer. “We simulate our IC (integrated circuit) design because we need to know if and how a design works before we receive the first chip. And, of course, we do a lot of simulation to understand how the device is performing wirelessly, so in the electromagnetic domain.” Fischer continues: “In the next design cycle, you can benefit from the simulation because you can understand any negative effects and try to avoid them in future designs. The things you learn in the process become part of your regular workflow.”

Simulation enables us to push ahead. I love simulation because it enables faster development, more precise development, and lets us stretch to the limits of physics. It's really cool.

MINIMIZE PHYSICAL TESTING AND SPEED PRODUCT DEVELOPMENT WITH SIMULIA

During development, various design challenges and the above needs lead to several product tests, both digitally and physically. Hearing aid performance data of interest typically includes, but is not limited to, measurements of the amount of amplification, frequency response, distortion, internal noise, current drain, telecoil sensitivity, directionality, automatic gain control, antenna performance and electromagnetic compatibility.

WSA conducts numerous physical tests in their own laboratories. Drop-testing labs, high-speed cameras, acoustics labs, and more populate these facilities. “We can create a restaurant situation in a controlled way [within our labs] such that we can listen to different settings of the hearing aid,” explains Menzl. WSA also tests their products in varying humidity’s and temperatures in their environment labs. “We can go from –20 degrees Celsius to 40 degrees Celsius [–4 degrees Fahrenheit to 104 degrees Fahrenheit] and back in less than a minute.”

Menzl remembers well the early days of hearing aid design and testing before digital simulation was widely employed. “A lot of things we do today with simulation we had to test [physically]. And many, many, many iterations were done to make something work and especially to ensure all the electronics worked.” With SIMULIA’s simulation tools, WSA can speed design and testing with digital technologies.

“Because of simulation we can make these devices smaller, more reliable, and longer lasting—really design them to the limit,” says Menzl. “Simulation enables us to push ahead. I love simulation because it enables faster & more precise development, and lets us stretch to the limits of physics. It’s really cool.”