Suzlon Energy

The wind turbine blade design company overhauls its quality management system to retain its ISO 9001 recertification and gains 80% productivity in design.

Setting new standards in wind turbine blade design

A skilled engineering team in the Netherlands develops state-of-the-art composite wind turbine blades for renewable energy solutions provider Suzlon Energy. It’s part of the Indian company’s blade division and delivers a complete design service, covering material, structural, aerodynamic and process design.

Most of the team have honed their skills in blade design over many years, evolving how they work to keep up with the latest digital advances. To help them work even more productively, they use the 3DEXPERIENCE® platform on the cloud for all design, and product data and project management.

“When I heard about the 3DEXPERIENCE platform, I knew it would completely transform our approach to design,” said Florens Wolters, manager of system automation and integration at Suzlon Energy. “It’s a new environment and philosophy of bringing things together on one platform, from design to project management. It presented an exciting opportunity for us to transform how we work for the better.”

What began as a project to overhaul the company’s existing quality management system for an ISO 9001 audit quickly turned into a wider initiative to streamline the company’s product data and break down silos across its design disciplines. As demand for renewable energy continues to skyrocket, Suzlon wanted to enhance its rotor blade design capabilities and boost innovation. Moving to the 3DEXPERIENCE platform held the promise of freeing its skilled designers from manual data management and administrative tasks to concentrate on what they do best.

“The aim was to improve the quality of design and make it faster,” said Harald Bersee, VP of blade design and integration at Suzlon Energy. “We wanted to automate our blade design concept studies as well as support activities like quality and project management.”

“Switching from a very complex quality management system to the 3DEXPERIENCE platform on the cloud encouraged us to make wider changes across our organization – gaining full control of our product data and automating tasks so we could deliver the same output and boost our design quality with the same resources,” Wolters added. “The philosophy was totally new and refreshing.”

We rebuilt our entire quality management system in the 3DEXPERIENCE platform. The auditor was impressed that we used the platform in such a way. We have retained our ISO certification without any fines. Now, when we have an audit, nobody panics.

Embracing the cloud for the better

When evaluating product lifecycle management (PLM) and quality management solutions on the market, it became clear that a cloud implementation would make sense for the Suzlon division, from both a cost and maintenance perspective. The small in-house team needed technology that could be installed easily, without additional servers or support, and guarantee data safety.

“IT is not our core business,” Wolters said. “We wanted to be able to focus more on design. It was a big deal for us to move to the cloud, but all our concerns around data security were addressed and it ended up being a great decision. Today, we know that our data is safeguarded in the platform. In fact, 3DEXPERIENCE was the pilot to prove the value of the cloud and we’re now embracing cloud-based software in other areas of our business.”

Suzlon’s technology partner Visiativ Benelux continues to guide the company through its digital transformation, delivering the expertise and support it needs to get the most from the 3DEXPERIENCE platform.

“It’s been a really successful cooperation,” Wolters said. “Visiativ was instrumental in starting the process. We had an abstract vision and needed their help to bring it to life. They supported us with the deployment and training and regularly checked in to keep us aware of new trends/changes so we could stay ahead. Most importantly, they understand where we came from and our needs, so they could translate them into our current solution.”

Saving time and boosting quality

One of the key areas that Suzlon wanted to improve with the 3DEXPERIENCE platform was document control. Having a clear process for creating, maintaining and accessing documents is critical for compliance with international standards such as ISO 9001. To pass its audit, Suzlon needed a robust quality management system with clear, simple workflows for version control and managing approvals of its blade designs.

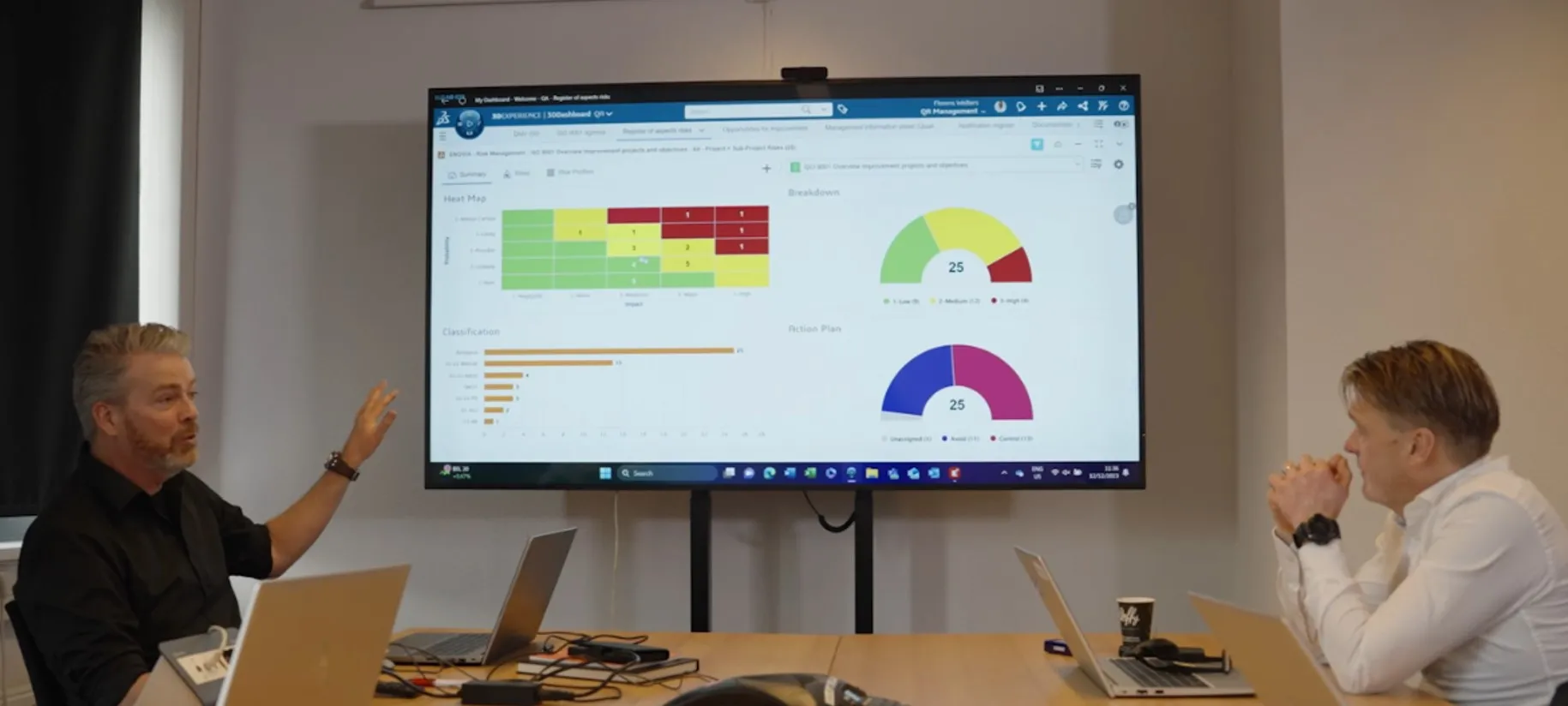

“We rebuilt our entire quality management system in the 3DEXPERIENCE platform,” Wolters said. “It made sense to tie it in with our PLM and the auditor was impressed that we used the platform in such a way. We have retained our ISO certification without any fines. Now, when we have an audit, nobody panics. We can open the dashboard and all the information we need is there.”

This new approach is also helping Wolters and his team work more productively. ENOVIA on the 3DEXPERIENCE platform delivers easy access to the information they need within a single dashboard.

“Switching to a new way of working and using the dashboards in the 3DEXPERIENCE platform save so much time; our output has really increased,” Bersee said. “If we need to calibrate machines, everything is now controlled better. It’s a really dynamic environment.”

Project management is far more efficient as well. Improved access to information means that the team spends less time in meetings and sending emails back and forth.

“Reducing meetings made it worth the transition to the 3DEXPERIENCE platform alone,” Wolters said. “Imagine saving an hour a day and multiplying that by 20 employees over a year. That’s huge. All planned tasks are now automatically diverted through the organization to the owner of the task so they can make their own updates; the platform keeps track of everything, including lessons learned from previous projects. Resources are linked to where they’ll be useful, and we have full control over our intellectual property. Management recognizes that we’re improving our communication and making fewer errors.”

Designing high-performance blades

Rotor blades are becoming larger as demand for higher capacity turbines grows – so they can produce even more electricity. Following the latest industry trends, Suzlon’s design team must define new materials and balancing loads, as well as the procedures to manufacture the blades in a robust way while maintaining a keen sense of costs.

Suzlon uses CATIA on the 3DEXPERIENCE platform to develop all its blades, transforming point clouds from aerodynamics into smooth surfaces and eventually mold designs. Access to all the design capabilities it needs within the platform helps boost quality and significantly improves productivity.

“We also use CATIA’s composites module to analyze the materials we use and do bill of materials analysis on everything from weight, fit and output to ensuring all the patterns are consistent,” Wolters said. “We must deliver high-quality and detailed design specifications ready for production. With CATIA we can do exactly that. It helps us work faster and more consistently – we’ve reduced our time in design by around 80%.”

Just as Suzlon benefits from transparency across its project management, design reviews have become more efficient too. All stakeholders can easily view designs, helping to rectify issues early on and keep track of approvals.

“All design disciplines, documents, deliverables, planning and risk management is connected on the platform,” Wolters said. “Non-CATIA users can look at 3D models during the design phase and provide feedback much earlier. The interface makes it easy to access information, write notes and push the approve or continue button before it goes to the next station. There are no duplicates floating around; no loose ends.”

The team is considering using CATIA for parametric design to work even more efficiently.

“We want to build up the blade design so that we can manipulate the model by numbers directly from the source,” Wolters said. “It’s becoming harder to find the talent we need, and we need to automate tasks to mitigate that.”

In pursuit of greater efficiencies

Today, Suzlon designs its rotor blades faster than ever within its lean organization. The team no longer relies on paper documents, templates and endless forms. Instead, it has access to a single source of data within the 3DEXPERIENCE platform.

“Everybody is in control of our data and documents,” Wolters said. “We’re now stepping into making our own widgets, which we can tune to our specific needs and help us break down information into even more manageable pieces.”

Based on the success it has achieved so far, Suzlon Energy is exploring how else it might take advantage of the 3DEXPERIENCE platform across its manufacturing operations in India and beyond. In particular, the company hopes to continually enhance how it uses CATIA to provide even higher quality design data that can feed into production and beyond.

“Looking ahead, we’re seeing how we may digitalize our business further and bring our blade designs to production in a more cohesive and visual manner,” Wolters said. “Moving to the 3DEXPERIENCE platform drives us to think further about how we can be more productive, present information in a better way and become more connected to the outside world. In a nutshell, it’s about starting small and ending globally.”

Discover more about the Concurrent Equipment Engineering industry solution experience.

Focus on Suzlon Energy

Based in India, Suzlon is one of the top renewable energy solution providers. Over the past two decades, the company has installed over 20.3 gigawatts of wind energy in 17 countries across six continents. In India, Suzlon is a market leader with more than 111 wind farms and an installed capacity of over 14,330 megawatts. It has developed some of Asia’s largest operational onshore wind farms in nine states, serving power utilities and electricity producers. The Suzlon Group aims to make renewable energy both simple and cost effective for customers.

For more information: https://www.suzlon.com

Focus on Visiativ Benelux

A subsidiary of Visiativ Group with 25 years of customer experience, Visiativ Benelux enables industrial companies to drive innovation, increase efficiency, reduce costs and improve quality through the integration and resourceful use of innovative technology solutions. It delivers tailor-made support to businesses, helping to facilitate their digital transformation and build new experiences for their entire ecosystem.

For more information: https://www.visiativ.com/en