SULO

SULO digitalizes over 150 processes across 8 sites with ITEROP to turn waste into valuable resources.

SULO, a Leading Player in Responsible Transformation

Since its creation, SULO is a committed and innovative player in waste management, a field that is essential for protecting the environment and public health. Building on its past successes and recognized expertise, the group is now strengthening its commitment by modernizing its processes through digital transformation.

This evolution is not a disruption, but a natural progression: by optimizing collaboration, improving operational efficiency, and strengthening traceability, SULO is not only maintaining its high standards, it’s exceeding them. With smarter, more agile process management, SULO continues to enhance its impact and responsiveness, reaffirming its leadership in ever more efficient and responsible waste management.

Digitalizing Processes to Turn Waste Into Resources

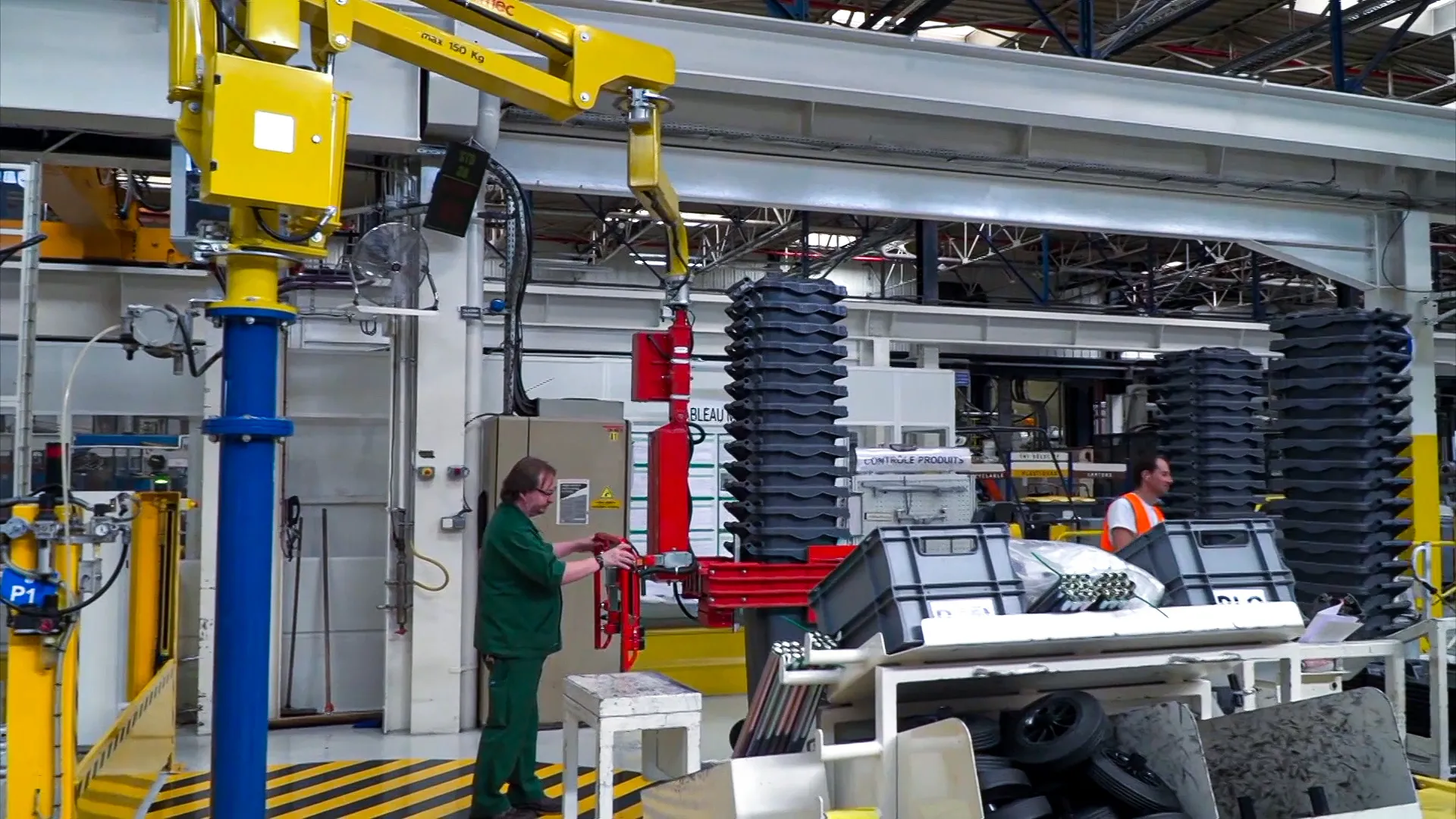

SULO is specialized in sustainable waste management and operates from eight production sites, employing more than 2,300 people.

As a pioneer in innovation and eco-design, SULO’s mission is to “turn today’s waste into tomorrow’s resources.” The group supports over 5,000 local authorities worldwide in their environmental transition by providing sustainable, value-driven, and meaningful solutions. It helps them improve collection, sorting, and recovery of waste, offering a wide range of products including collection bins, voluntary drop-off points, compactors, underground and semi-underground containers, street bins, and pre-sorting and biowaste solutions as well as innovative digital tools.

At the heart of SULO’s strategy, digital technology plays a key role in deeply transforming waste management practices and maximizing environmental performance. These solutions enable real-time monitoring of equipment levels and conditions, optimization of collection routes, easier maintenance, and improved operational efficiency for public services. Through an intuitive software platform, incentive-based pay-as-you-throw systems, and connected hardware components, SULO helps communities streamline operations, reduce costs, and enhance the quality of service provided to residents. SULO also offers bin repair, maintenance, cleaning, and replacement services.

Gaining Traceability and Operational Visibility

As an active promoter of the circular economy, SULO supports its clients in reducing their environmental footprint through a diverse range of activities. To ensure the efficiency and sustainability of these initiatives, the company must maintain control over several strategic levers: strict compliance with safety standards — essential to operational reliability — maintaining a high level of customer satisfaction — key to reputation and competitiveness — and rigorous management of supplier relationships, ensuring a responsible and high-performing supply chain.

Among the various sites, the Herford plant in Germany clearly illustrated the challenges faced in ensuring transport safety and compliance.

At that time, there was no clear procedure to handle trucks that did not meet safety requirements. Loading teams sometimes had to spend time finding the right contact person in case of issues, leading to inefficiencies and a lack of consistency in follow-up. In addition, some customer claims related to load securing highlighted the need for greater traceability to demonstrate that operations carried out on site were compliant.

These observations revealed a broader need to strengthen traceability and visibility across all processes, in order to ensure proper monitoring of complaints and identify root causes more effectively.

We found ourselves with many collection points and multiple internal and external stakeholders, a strong need for transport traceability and a real necessity to control costs.

Implementing ITEROP BPM

In 2019, faced with these multiple challenges, SULO decided to simplify its internal processes and improve collaboration and communication between stakeholders. To achieve this, the group adopted Dassault Systèmes’ Business Process Management (BPM) solution, ITEROP, enabling the digitalization and automation of its processes to enhance monitoring and analysis capabilities.

Ease of use also played a decisive role in selecting the solution, as it needed to be accessible and fully operational on the shop floor without unnecessary complexity. The “low-code” approach was another key requirement for SULO, allowing processes to be designed in an agile manner without advanced technical skills or lengthy IT training. This flexibility was essential for adapting or modifying processes in real time based on evolving business needs, while ensuring maximum autonomy for local teams.

The solution was first deployed at the Langres site before being progressively rolled out to other sites across the group. One of the first processes to be digitalized was customer complaint management. Before ITEROP, the Quality team used a dedicated tracking tool alongside a manual Excel sheet, which complicated traceability and data consistency, leading to many manual follow-ups. Now, complaints are processed directly within the solution, improving responsiveness and reliability.

One of the major advantages in adopting this new approach was the integration of QR codes on delivery notes. By scanning these codes with a smartphone or tablet, customers can submit a complaint in just a few clicks. This functionality not only simplifies the process for customers but also automatically enriches the database with precise information. These enhanced data enable more detailed analysis of complaint causes and trends, facilitating the implementation of targeted corrective actions.

The group’s BPM digitalization project was carried out progressively and methodically. Initially, the goal was to optimize key processes and ensure gradual adoption of the solution by teams. A second phase, known as the “expansion” phase, then enabled the deployment of more complex and ambitious processes.

To drive this second phase, “process design leads” were appointed at several pilot sites. Their dual role was to manage process digitalization locally and ensure operational mastery of the project. Close to the field and trained in ITEROP, these leads worked closely with process owners. They also received methodological and technical support from ITEROP administrators, ensuring consistent and effective implementation.

In 2022 it became clear to us that the pilot site had matured, processes were already reaching other sites. We then launched the deployment and structured our governance approach.

Thus, the Herford site was able to implement the truck safety compliance process and adapt it to local constraints. It now includes a mandatory Safety Check before loading to ensure that all trucks comply with safety standards. Once loading is complete, a load securing check is also carried out. Documentation of these checks is stored within the solution, and users can upload photos as proof in case of issues.

Regarding the management of used bin transport, the new process was implemented as a complement to SULO’s existing ERP system. It has enabled the involvement of all stakeholders: customers, the logistics department, external transporters, and the recycling company.

The BPM solution also allows us to complement existing business software.

Finally, the technical inspection process for forklifts was also digitalized, enabling the tracking of costs associated with malfunctions and anticipating maintenance expenses. At the start of each shift, drivers complete a predefined checklist. If a malfunction is identified, an alert is automatically sent to the supervisor and maintenance team. The associated resolution process has also been integrated into the solution for efficient handling.

To roll out these processes, SULO relied on designer training and the support of the BPM user community to ensure best practices were adopted throughout the journey.

Digitalized Processes for Greater Fluidity and Productivity

The implementation of the BPM solution brought numerous measurable benefits to SULO, including cost savings, increased productivity and efficiency, and improved collaboration and communication across teams.

SULO can now easily ensure that only trucks compliant with safety standards are loaded. The digitalized transport management process for used bins has allowed the company to handle higher collection volumes without adding staff. The forklift inspection process has also helped anticipate potential maintenance costs.

Productivity and efficiency have reached optimal levels thanks to automatic task reminders and reduced manual work. Some collection circuits have become fully autonomous, eliminating the need for transport managers’ intervention and simplifying staff substitutions during absences.

With the active involvement of operational teams, customer complaints are processed instantly, and compliance plans for forklifts are easily shared. All this has improved both internal and external communication and collaboration, while enabling better tracking of maintenance costs.

The clarity of roles and responsibilities within SULO’s digitalized processes ensures that every team member has the necessary information to perform their tasks and collaborate effectively.

Toward Stronger Expertise and Sustainable Efficiency

Promising perspectives are emerging regarding skill development and the long-term use of the solution within the SULO group. At the Langres site, the goal is to strengthen internal expertise through the ITEROP training program, which includes several certification levels. This program allows employees to progress step by step, from initial training to autonomous process design. The target is for all managers to reach level 2 (process launching and usage) and for each department to have at least one lead trained to level 3 (advanced training), ensuring expert and consistent use of the solution over time.

SULO is thus securing its operations and continuously enhancing efficiency and productivity by adopting an agile approach adapted to the company’s and industry’s evolving needs.

Processes evolve alongside the life of the company. They are therefore always up to date.

Focus on SULO

SULO is a leading player in sustainable waste management and a pioneer in eco-design. The group designs and manufactures innovative solutions for waste collection, sorting, and recovery, supporting over 5,000 local authorities in their environmental transition.

With more than 2,300 employees across 8 production sites in Europe, SULO is committed to transforming today’s waste into tomorrow’s resources while continuously improving

For more information: https://sulo.com