Sky Eye Systems

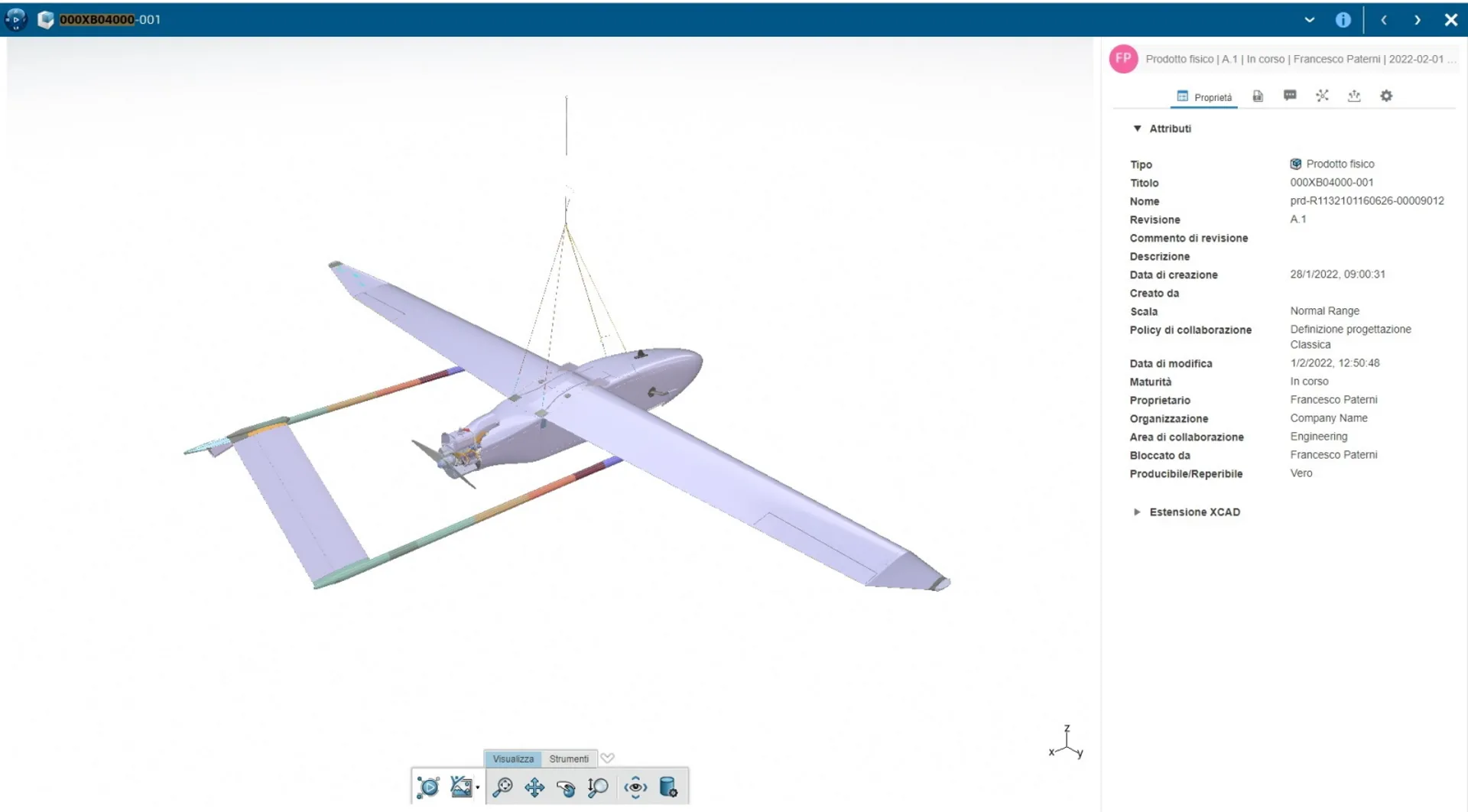

Sky Eye Systems is a specialist in small, tactical, unmanned aircraft systems (UAS). To bring its Rapier aircraft to market, the Italian startup selected the 3DEXPERIENCE Cloud platform and the Reinvent the Sky industry solution experience to enable visibility and collaboration between designers and engineers and speed up development processes.

The platform is naturally a collaborative space and is helping us to securely share information with those who need it. For example, our cable integrator now benefits from being able to see a detailed 3D model of the routing. This leaves less room for misinterpretation and mistakes.

Certifying lightweight tactical unmanned aircraft systems

If you’ve ever looked up and seen a small drone – also known as an unmanned aerial vehicle (UAV) – hovering in the sky, what you may not know is it that the aircraft itself doesn’t require certification to fly. So long as the owner is registered and the UAV weighs no more than 25 kilograms and operates within the strict limits set by the local aviation authority – for example it avoids flying directly over people and no-fly zones – it’s good to go. Using drones for commercial reasons, national security operations and long-range travel is another matter. Although most weighing under 25 kilograms still aren’t certified. And that’s where Sky Eye Systems’ Rapier X-25 stands out.

Developed by Italian unmanned aircraft systems (UAS) specialist Sky Eye Systems, recently awarded Military Design Organization Approval by the Italian Directorate of Air Armaments and Airworthiness (DAAA), the Rapier X-25 is one of the most efficient, sophisticated, and safest remotely piloted aircraft systems on the market in its weight category. It is among the first in the mini class to achieve the Military Type Certification, demonstrating its compliance with strict airworthiness and military operational requirements recognized by the DAAA. Weighing up to 25 kilograms, the tactical drone is designed for applications covering intelligence, surveillance and reconnaissance (ISR), mapping, pollution control and natural disaster monitoring.

“Sky Eye Systems has one of the only certified UAVs in this category, meaning it can fly without restriction,” said Giovanni Fumia, former head of marketing and sales at Sky Eye Systems. “This is because we have demonstrated that our design and development processes are in perfect alignment with public authority regulations, and we carry out thorough testing of all structural parts following industry norms to achieve the highest level of safety certification.”

It may be light weight, yet the Rapier X-25 can perform missions similar to higher class UAVs, thanks to its 16-hour flight endurance, 100 kilometer datalink range and sophisticated onboard sensor payload capabilities. The drone brings to life the company’s vision of building a new family of small, tactical UAVs and becoming a world leader in the lightweight segment.

As interest in the company’s aircraft grows and it looks to expand its portfolio, Sky Eye Systems required a centralized data platform for robust product lifecycle management (PLM). It needed to be able to track changes and design modifications and bring full visibility to every aspect of the product development lifecycle. All these requirements were met in the 3DEXPERIENCE platform on the cloud.

“We wanted a platform to guarantee a single source of truth throughout the company,” Fumia said. “Before, we worked on local servers and used shared folders and there was always a risk of using obsolete information and overwriting critical data. Then there are all the issues related to configuration and change management. We have audits with military authorities, so this aspect is critical. We need to clearly show our workflows and see the entire history of all the changes we make to the aircraft.”

Rapier X-25: Key Data

- Up to 25 kg

Weight

- 16 hours

flight endurance

- 100 kilometers

datalink range

Up to speed on the cloud

Sky Eye Systems received expert advice from Dassault Systèmes partner Cad Solution Provider (CSP) to ensure the 3DEXPERIENCE platform on the cloud would best meet its needs.

“CSP have played an essential role in this implementation,” Fumia said. “At the start of the process, we showed them how we work and what we wanted to achieve. They helped us to identify our requirements and demonstrated how the platform would help us. Since then, they have delivered ongoing advice and support to ensure we get the most from this technology.”

A cloud version of the 3DEXPERIENCE platform was a clear choice for the startup, allowing it to get up to speed without needing an established server infrastructure or making a big upfront investment.

“All we needed was a good and stable internet connection,” said Francesco Paterni, design engineer at Sky Eye Systems. “For a small company like us, it’s much more efficient to use the cloud than build a complex IT architecture. The cloud solution also guarantees maximum uptime, even if there’s a local disaster, and the in-built security assures us that our data is always safe. It’s cost effective and we appreciate the out of the box functionality with all best practices already embedded in the platform.”

Fumia explained how the platform’s inbuilt methodologies and best practices help a young company comply with established aviation industry standards.

“I’d certainly recommend the 3DEXPERIENCE platform to a startup,” he said. “It’s really easy to implement and will scale with our needs as we grow. It’s also much more efficient for a small, young company like us to embrace the best practices of the platform with the new methodology and ways of working, rather than a larger company which may have to undo years of working in their own way and try to adapt.”

Connecting CAD data to the platform

Critically, Sky Eye Systems has managed the aircraft certification process entirely on the 3DEXPERIENCE platform.

“It allows us to be guided by recognized industry best practice and comply with various standards, such as simulating the effects of an airborne bird strike and showing the engine and airframe can withstand such damage,” Fumia said. “We can manage and store all test results and documents in a single place and use them as evidence to demonstrate compliance. It also means we can obtain the information we need and know that everything is controlled and protected from unauthorized changes while preventing the use of obsolete documents. During design reviews, we can prove the integrity of our documentation.”

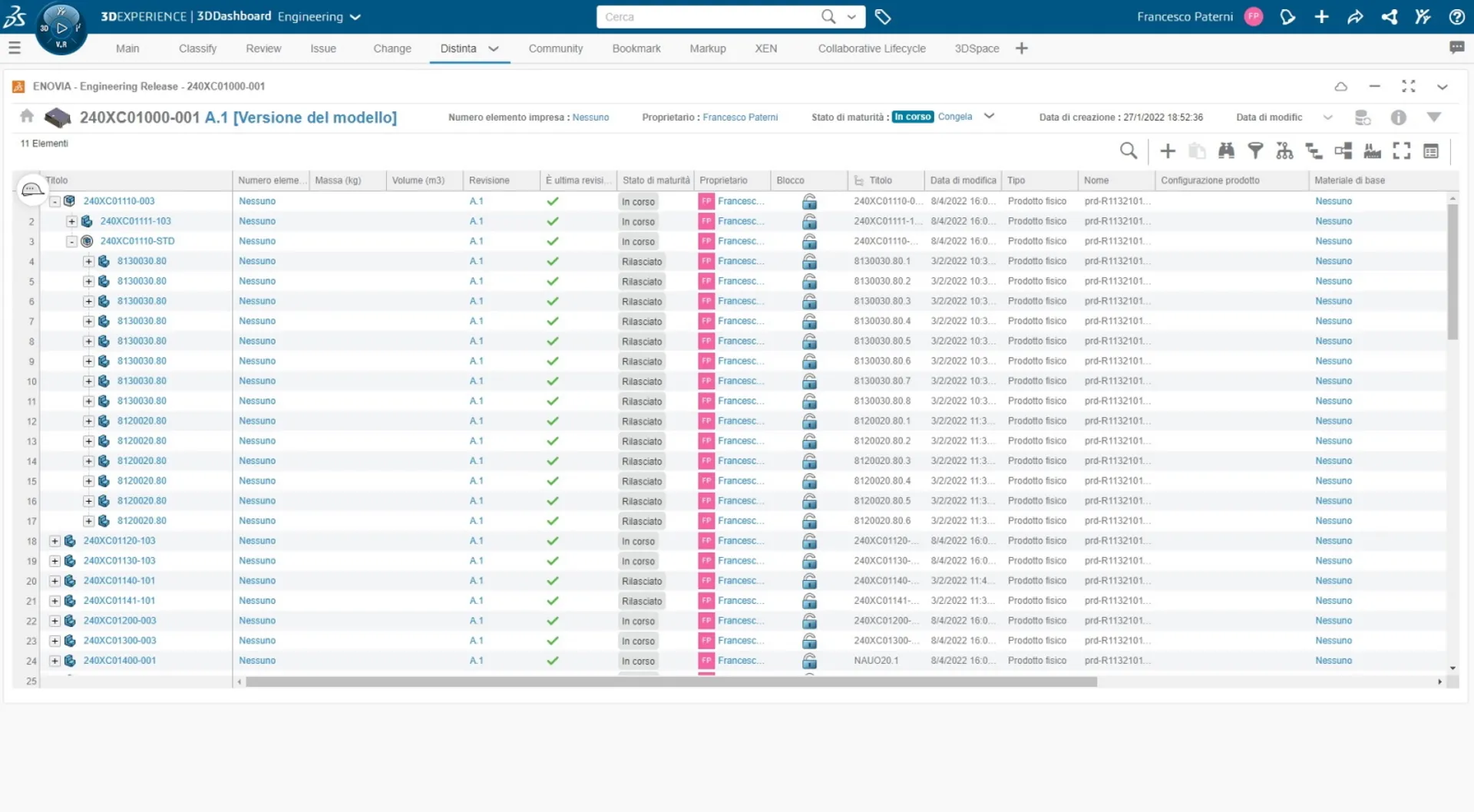

As part of its digital transformation journey, Sky Eye Systems has connected five years’ worth of CATIA V5 CAD data to the 3DEXPERIENCE platform. Using ENOVIA POWER’BY, it is now able to take advantage of the 3DEXPERIENCE platform methodology and collaboration capabilities while still using CATIA V5.

“The transition is smooth with POWER’BY,” Paterni said. “We can now seamlessly save all our data on the cloud instead of in local folders. From a design engineer’s perspective, it means we don’t have to learn to use a new tool. It allows us to satisfy the needs of both our established engineers and the new generation of talent coming through that want to work with more modern tools.”

Optimized to fly

The company uses the powerful surface modelling capabilities in CATIA on the platform to ensure optimal aerodynamic performance in the Rapier X-25.

“With CATIA we can define complex surfaces and check the results for inflections,” Paterni said. “The aerodynamics department designed the entire aircraft shape in CATIA and used its surface modeling tools to create a well-designed surface that leads to a well-manufactured component. The skin of the wing is made of composites and is perfectly smooth with no imperfections.”

Sky Eye Systems also uses CATIA to design composites parts and improve light weighting.

“We can compare various materials and geometries in real time to determine the best material and weight,” Paterni said. “ A half-wing, for example, has a 1.7 meter span and weighs less than a bottle of water. It’s always a challenge to obtain the lowest possible weight within the technological production limits, but CATIA is a great tool for allowing us to do this. The composites modeling capabilities also allow us to reduce time to market. Before we’d have had to create lots of time consuming 2D drawings at the preliminary stage before progressing to the detailed design phases. Now, we can do all of this digitally and take into account manufacturability requirements from the start.”

A collaborative, multidisciplinary space

With all disciplines collaborating on the 3DEXPERIENCE platform, including electronics, mechanical and software engineering, everyone at Sky Eye Systems has full visibility of the product development process and can access the information they need.

“Even though we are a small company, we still have various departments to produce our products,” Paterni said. “Now, everyone can store, manage and share data on the same platform with the same interface. In less than a second, they can pull up the right information. It’s far faster than searching through folders on local drives or sending emails back and forth.”

With ENOVIA, concurrent engineering on the 3DEXPERIENCE platform enables Sky Eye Systems to identify and mitigate any issues early on, from software to mechanical design.

“It also supports engineering bill of materials (BOM) and manufacturing BOM management,” Paterni said. “From the start, we have a digital mockup of the aircraft and 3D assembly that contains all information about the configuration. We can modify various aspects like structural additives and the BOM automatically updates.”

The platform is easing collaboration with suppliers too.

“It’s naturally a collaborative space and is helping us to securely share information with those who need it,” Paterni added. “For example, our cable integrator now benefits from being able to see a detailed 3D model of the routing. This leaves less room for misinterpretation and mistakes.”

In future, the company hopes to take advantage of the product and manufacturing process simulation features in the 3DEXPERIENCE platform to further enhance efficiencies.

“I can really see how we would benefit from being able to simulate such things as the aircraft’s aerodynamics and the functioning behavior of each of the different parts and how they work together,” Fumia said.

Launching new UAV models

The company is currently working on a new version of its product – the Rapier X-VTOL, which has two tandem engines for horizontal flight and eight electric engines for vertical flight. The hybrid energy aircraft shares most of the key technologies developed by Sky Eye for the Rapier family.

“The Rapier X-25 is fully developed and certified,” Fumia said. “The Rapier SkySAR model is 90% complete and the X-VTOL is under development and will share 70% of the technology from our other platforms in terms of the flight control system and wing layout. ENOVIA is helpful for tracing all the changes we’ve made on the various Rapier configurations and ensuring that carries through into future models.”

As Sky Eye Systems gets fully up to speed on the 3DEXPERIENCE platform, it hopes to accelerate the design and testing stage for each of its UAVs, and comfortably meet key milestones and completion dates.

“We expect to reduce time to market and resolve any design problems at the earliest stage, helping us to achieve our main goal, which is to save time and money,” Paterni said. “We are aiming for a time saving of at least 30% in product development. Our teams already see the benefits of working on the 3DEXPERIENCE platform. It is clear that it can answer our needs, now and in the future.”

Discover more about the Reinvent The Sky industry solution experience.

Focus on Sky Eye Systems

Founded in 2017, Sky Eye Systems is an Italian aeronautical company created to develop a new family of small tactical UAS weighing between 25 and 50 kilograms. Its team is composed of highly skilled managers, engineers and technicians, with extensive experience in international aeronautic programs, capable of developing proprietary UAS with top class performance. This specific know-how empowers Sky Eye to reduce time to market, costs and development related risks – a benefit for both civil and military customers.

For more information: www.skyeyesystems.it

Focus on Cad Solution Provider

Cad Solution Provider (CSP) is a subsidiary of Cadland Group and distributes Dassault Systèmes software throughout Italy. The company is a PLM Certified Reseller and Dassault Systemes Certified Education Partner, delivering high quality training on the Dassault Systèmes software portfolio. With its extensive expertise, CSP guarantees its customers the highest quality services and products.