SAH Hortum

Turkey-based manufacturer of rubber hoses SAH Hortum creates 3D models of its hoses 30% faster and with greater accuracy – validating their manufacturability right from the beginning thanks to the 3DEXPERIENCE platform on the cloud. The Digital Equipment Continuity industry solution experience enables it to create a digital thread across its entire business, from design to manufacturing.

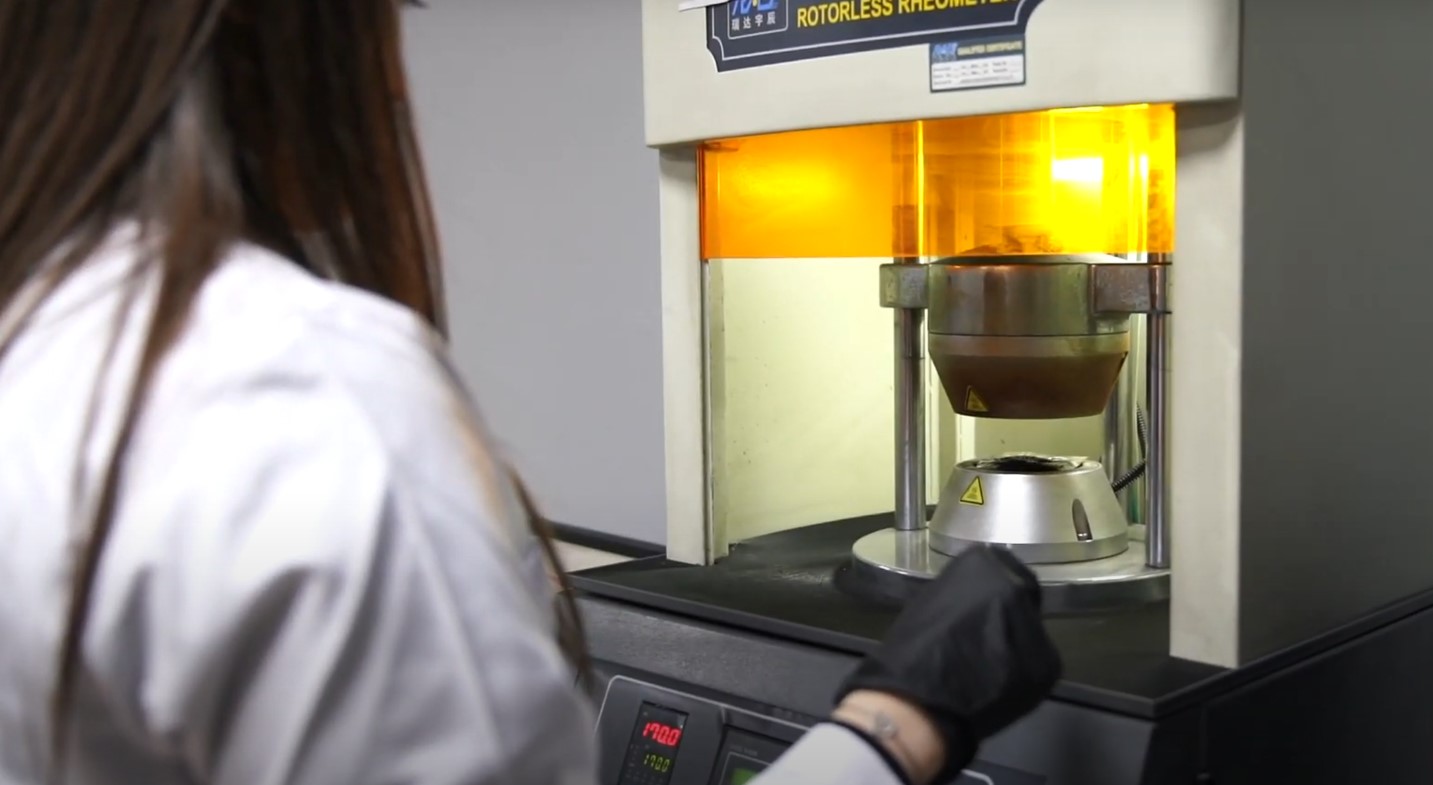

Manufacturing high-quality rubber hoses

In 1839, the American inventor Charles Goodyear accidentally dropped some sulfur-coated natural rubber onto a hot stove. This process – which he later named ‘vulcanization’ – created a material that was strong, durable and resistant to temperature changes.

Thanks to this discovery, vulcanized rubber became a highly-sought-after material used for a wide range of products, including hoses, which remain a fundamental component of almost every type of vehicle, as well as kitchen appliances, air conditioning devices and more.

One company that has mastered the production of high-quality rubber hoses is Turkey-based SAH Hortum. While only a modest-sized establishment of 50 people, it supplies more than 1,300 different hose products to major automotive manufacturers and consumer brands in over 20 countries.

How does a small company operate on such a large scale? By using technology like Dassault Systèmes’ 3DEXPERIENCE® platform on the cloud.

Thanks to the capabilities of the 3DEXPERIENCE platform on the cloud, along with the support of Cadem Digital, we have been able to position ourselves as a leader in our industry and deliver a very professional service to our customers.

Challenge

Before implementing the 3DEXPERIENCE platform, SAH Hortum manufactured its products using basic 2D drawings that were supplied by its customers. Unable to model or validate its products in advance, its engineering team relied heavily on its experience and trial and error, which could lead to inaccuracies in the manufactured product.

The company sought a 3D design solution that could help it work more efficiently. With limited budget and in-house resources, the platform needed to be fast and easy to implement, as well as simple and quick to learn.

Solution

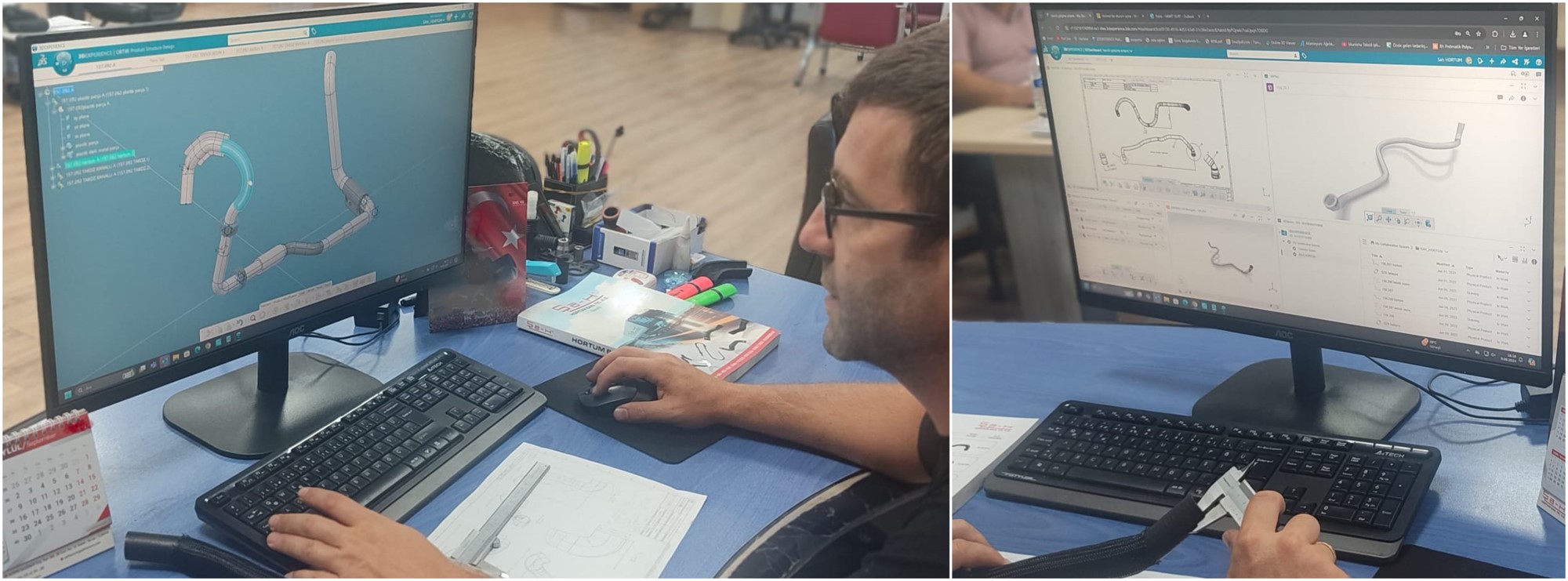

After reviewing multiple 3D design offerings, SAH Hortum saw a demo of Dassault Systèmes’ 3DEXPERIENCE platform on the cloud. The company learnt how the platform could not only provide it with CATIA for 3D design, but also ENOVIA for product lifecycle management (PLM), which would create a digital link between design and manufacturing.

The cloud-based environment was a big selling point: It meant implementation would be quick and SAH Hortum would not have to manage its own servers, software updates, or data security.

Having decided on the solution, local partner Cadem Digital stepped in to deliver support. After just two days of training on CATIA and three days of training on ENOVIA, the company was ready to go.

Benefits

Today, the 3DEXPERIENCE platform on the cloud serves as a single source of truth for SAH Hortum, from design through to manufacturing.

Thanks to CATIA, the company now has an industry-standard design tool that enables it to create 3D models of its hoses quickly with great accuracy – validating their manufacturability right from the beginning. The application helped the company to quicken the design cycle time by saving and reusing common components of its products, avoiding the need to start from scratch when creating new designs. SAH Hortum estimates that CATIA has enabled it to work 30% faster than before.

At the same time, ENOVIA’s PLM capabilities enable the company to store all the data and information related to its products – such as specifications, technical manuals or PDF documents from the customer – in one place. Being able to access everything from the same location saves additional time and effort and ensures consistency.

Moreover, SAH Hortum’s newfound ability to create 3D designs using the latest version of the 3DEXPERIENCE platform has allowed it to not only meet, but surpass its customer expectations, and has positioned it as a leader in its field.

Following the success of the platform to date, SAH Hortum is looking to expand its user base to benefit from collaboration features. It also is planning to connect its new enterprise resource planning solution with the platform, so that it can enjoy even greater integration advantages.

Discover more about the Digital Equipment Continuity industry solution experience.

Focus on SAH Hortum

Founded in Turkey in 1980, SAH Hortum supplies rubber hoses to the aftermarket, white goods and construction equipment sectors around the world. The company creates its products using the latest production techniques from its 10,000 square meter production facility.

For more information: https://www.sahhortum.com/en-US

Focus on Cadem Digital

Operating in digital transformation since 1998, Cadem Digital offers PLM and 3DEXPERIENCE platform solutions to provide its customers with improved speed and productivity across the full product development lifecycle. It provides innovative, integrated technologies in industrial manufacturing processes primarily for the automotive industry along with aviation, defense and machinery. Cadem Digital is a reliable, experienced and innovative solution partner in the digital transformation journey of brands in the process of creating their future, empowered by its experience and expertise in digitalization, technology, education and innovation in the industry.