KG Constructions

Facade contractor KG Constructions introduced the 3DEXPERIENCE platform on the cloud and its Building Design for Fabrication industry solution experience allowing an increase in design, engineering and manufacturing efficiency. It saves the company about 30% of the time it would take using traditional methods.

The experts behind the facade

KG Constructions has established itself as one of the biggest facade contractors in Northern Europe, serving general contractors, investors and developers across the region. But it isn’t resting on its laurels.

“We are currently expanding into the UK and Switzerland,” said Andrius Nikolajevas, the company’s head of design. “Our main product is unitized curtain walls. These large units are manufactured and assembled in our factory, transported to the site and then installed on the building. We implement the most complex customer ideas and find the best balance between aesthetics, cost and effectiveness for every project.”

The company currently employs 400 people across the Group, but has lofty ambitions for the future. “We expect to add at least 100 more employees in the short term,” said Nikolajevas.

But achieving growth in an incredibly competitive industry like construction is no easy feat. “If we want to meet our goals and get ahead of our peers, then we need to stay wide awake,” Nikolajevas said. “We have to listen to our customers and pay close attention to changes in the market.”

This means getting serious about burning issues such as sustainability. “A couple of years ago only a few contractors cared about sustainability, but now we have to be fully onboard with it,” Nikolajevas said. “We have to establish concrete plans, implement official strategies and meet growing regulatory requirements around CO2 emissions, waste reduction and more.”

Generating sustainable success

As a result, KG Constructions has set out its five-year sustainability strategy, which outlines its commitment to reducing CO2 emissions to zero by 2025, and explains how it will achieve a responsible supply chain and better its efforts around cybersecurity, employee health and well-being, waste reduction, product sustainability and operational efficiency.

“We’ve realized that sustainability is about much more than being green,” said Nikolajevas. “It’s also about taking care of our employees, communities and our customers. Our new sustainability strategy will help us adapt to new market requirements and ensure we stay competitive.”

At the same time, the company has to meet the ever-growing demands of its customers. “Every project we embark on is unique,” Nikolajevas said. “Architecture needs to align with stringent construction standards and fulfill strict project requirements too. Expectations are rising – our clients are now demanding bespoke glazing, specialist leaned facades and multiple cladding facade systems.”

This is a lot to manage from a design, engineering and manufacturing perspective. “Every year, requirements are getting more complex,” Nikolajevas said. “Now, almost every building we work on needs not only Building Information Modeling (BIM), but also detailed 3D design for fabrication. With this, we can access more accurate information for production faster. It also means that all stakeholders can experiment with designs and iron out any issues before construction.”

Using the 3DEXPERIENCE platform, we estimate that we saved 30% of the time it would have taken using traditional methods.

In search of greater efficiency

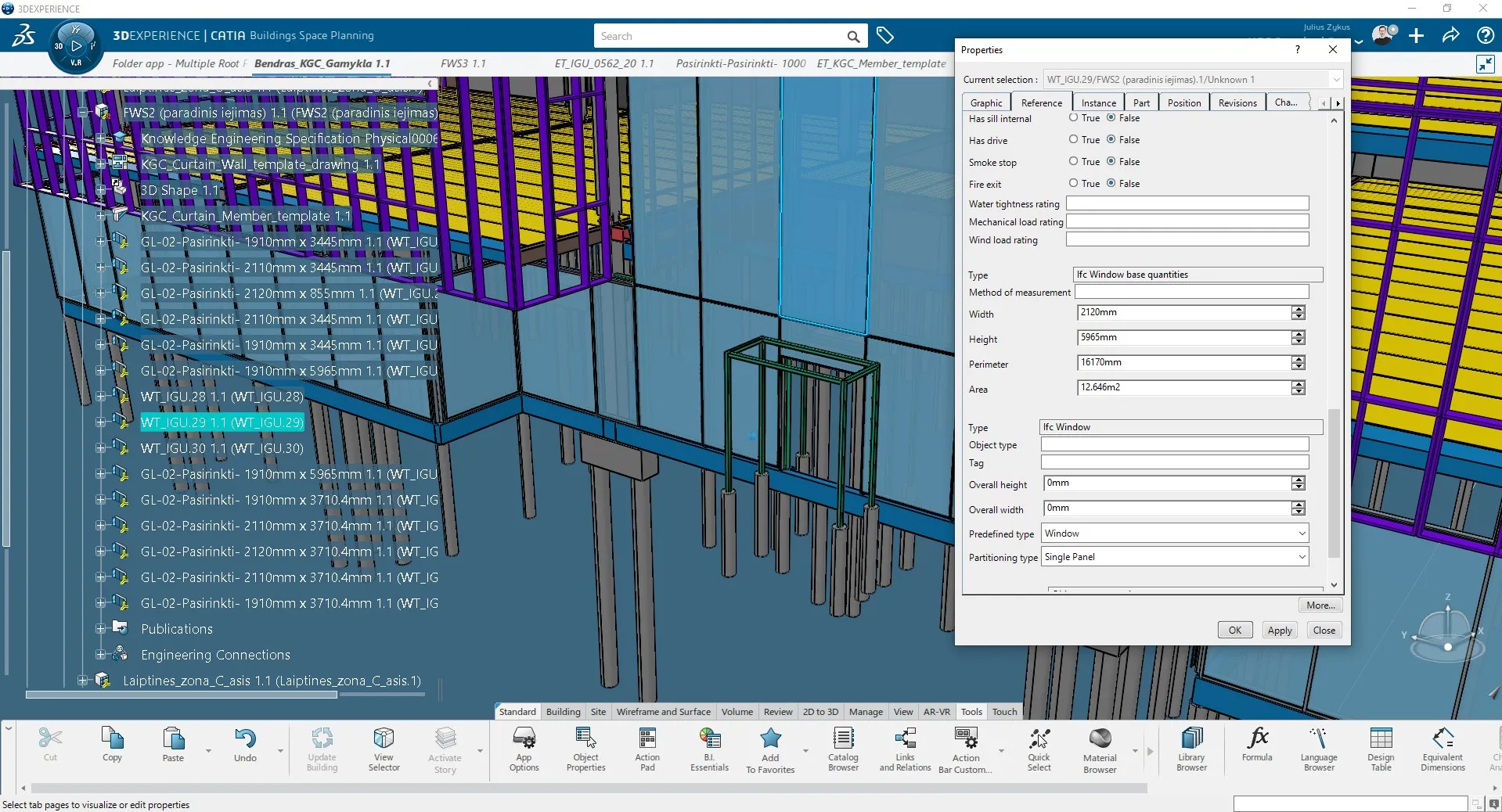

Unfortunately, however, the 3D design programs that the KG Constructions design team had trialed were limited. “We tested countless 3D modeling platforms, but none of them were flexible enough for our needs,” said Julius Zykus, design team lead at KG Constructions. “They were unable to deliver bills of materials (BOMs) for industrialization. We wanted a solution that could unify BIM and product lifecycle management (PLM) to create virtual twins of our construction projects.”

“We were at a loss of what to do,” Nikolajevas said. “The only way for us to ensure our future growth was to become more efficient and innovative. We knew we needed a new technology platform that could help us capitalize know-how about construction knowledge. We wanted to align our processes so that we could deliver data from design to manufacturing. And we wanted to be able to design in 3D and get to the stage where all processes benefit from that.”

Having almost given up their search, Nikolajevas and Zykus discovered the 3DEXPERIENCE® platform. “Dassault Systèmes’ 3DEXPERIENCE platform, and specifically its CATIA application, offered something different,” said Nikolajevas. “It had the flexibility that we were looking for.”

“CATIA’s 3D modeling and simulation capabilities promised to optimize the effectiveness of each and every one of our users,” Zykus added. “The software would allow us not only to model any facade, but to do so in the context of its real-life environment. At last, we had a solution that could deliver the results we were looking for.”

The sky's the limit

In order to achieve maximum efficiency gains, the company chose to implement the solution on the cloud. “The cloud is very flexible – you can connect from wherever you want, and be sure that you are working with the latest models,” said Zykus. “There’s no need to worry about the costs or management of a local server, and all security requirements are in-built. All you need is a good internet connection and you are away.”

This new way of working did bring some challenges, however. “We experienced a massive culture shock,” Zykus said. “Working via the cloud in this way required a totally different file management system, and we faced resistance from our employees about this.”

“We understood exactly what the platform could do, and how it could be achieved, but it was incredibly difficult to change years-old ways of working,” Nikolajevas added. “But we recognized we needed to move forward – and that meant enforcing change.”

This was achieved with help from Dassault Systèmes’ partner RAND Finland Oy. “We did some training in Eduspace to get the hang of the platform,” said Zykus. “We also watched video blogs and other video lessons. We had some webinars with RAND Finland Oy too, and a three-day learning session with Dassault Systèmes.”

But Nikolajevas realized that the most effective way of learning the platform was simply to use it. “That’s why, in order to facilitate change in the most effective way, we decided to use the 3DEXPERIENCE platform to fully design our new factory in Vilnius, Lithuania,” he said.

CATIA’s 3D modeling and simulation capabilities promised to optimize the effectiveness of each and every one of our users. The software would allow us not only to model any facade, but to do so in the context of its real-life environment.

Building knowledge

The new factory will be built on a six-hectare plot, and development will happen in two stages. “The first stage will see us build a factory of 13,800 square meters, along with an administrative building to manufacture KG Constructions’ aluminum-glass facade products,” said Nikolajevas. “We plan to install six element assembly lines, and a separate window and door assembly line in the factory. It will double our current production capacity.”

In addition to the new factory, a modern, first class, three-story office building with a total area of 2,620 square meters will be constructed. “The construction process has already begun,” Nikolajevas said.

In the second stage of the project development, another 7,000 square meter production factory with an administrative building is planned, which will be allocated to the subsidiary of the group, UAB Lignas. Construction is scheduled to begin in 2023.

“This project was a huge test for the 3DEXPERIENCE platform,” said Nikolajevas.

Thankfully, it was a hit. “We used the platform to help us design, build and manufacture the entirety of the new fabrication plant,” said Zykus. “We implemented all key processes from the platform, using 3D modeling to create the BIM and visualize the factory as a whole. We were able to automatically create a bill of materials (BOM), which previously we’d have done manually. This meant there was no chance of errors – which is fantastic.”

Collaboration was much improved. “We are all working in the same space,” said Zykus. “There’s no longer a need to create multiple copies of designs, so we are always working on the latest version.”

The team was able to move from design to manufacturing without any 2D drawings, and without any mechanical work. “It was incredibly efficient,” said Nikolajevas. “Using the 3DEXPERIENCE platform, we estimate that we saved 30% of the time it would have taken using traditional methods.”

Constructing the future

As a result of this success, Nikolajevas is confident that the 3DEXPERIENCE platform will play a major part in KG Constructions’ future. “If I were asked to describe our relationship with the software, I would say we are ‘just married’,” he said. “But it’s incredibly promising. I think it will help us drive forward with future projects, particularly because – thanks to ENOVIA – we can reuse information and optimize designs very easily. We can also present our ideas in a more attractive way. And, because everything is now so accurate, we can make sure we manufacture our products right first time, which means we reduce waste. This will support our sustainability strategy.”

Nikolajevas is keen to get even more from the software. “We want to be able to transfer data from our 3D designs to other departments,” he said. “And we want to explore the use of different apps such as DELMIA and ENOVIA so that we can handle projects more efficiently. We are also looking to implement a CO2 calculation inside the platform, which will take a massive burden away from us as this is currently done manually.”

Ultimately, Nikolajevas believes that the 3DEXPERIENCE platform will help his company stay one step ahead. “We are a part of a network that is transforming the industry,” he said. “The facade engineering sector is always a few steps forward compared to other areas of construction. Thanks to our adoption of Dassault Systèmes’ technology, we can really help the industry move forward. We are on the path to design freedom – and that is incredibly attractive to our customers.”

Focus on KG Constructions

KG Constructions is one of the largest producers of aluminum and glass facade structures in Baltic and Scandinavian countries. Its focus on continuous improvement has enabled it to realize unique architectural building visions through a vast range of services such as technical preparation and pre-design testing, design, project management, production, logistics, installation and warranty services.

For more information: www.kgcgroup.com

Focus on RAND Finland Oy

RAND Finland Oy specializes in product data management, Product Lifecycle Management (PLM), CAD/CAM, Realistic Simulations (FEA), and sales/product configurator initiatives. RAND Finland Oy delivers turnkey solutions and services for the initiatives above. The cornerstone of our success is experienced and skilled people. RAND has +20 years of experience in delivering PLM solutions to Finnish, Nordic, and also global customers. In addition to RAND’s own team, it has a very wide network of professionals to complement its offerings. RAND Finland Oy specializes in the following Dassault Systèmes software solutions: 3DEXPERIENCE, CATIA, SIMULIA, DELMIA, EXALEAD, and ENOVIA.