Horst Hoopmann

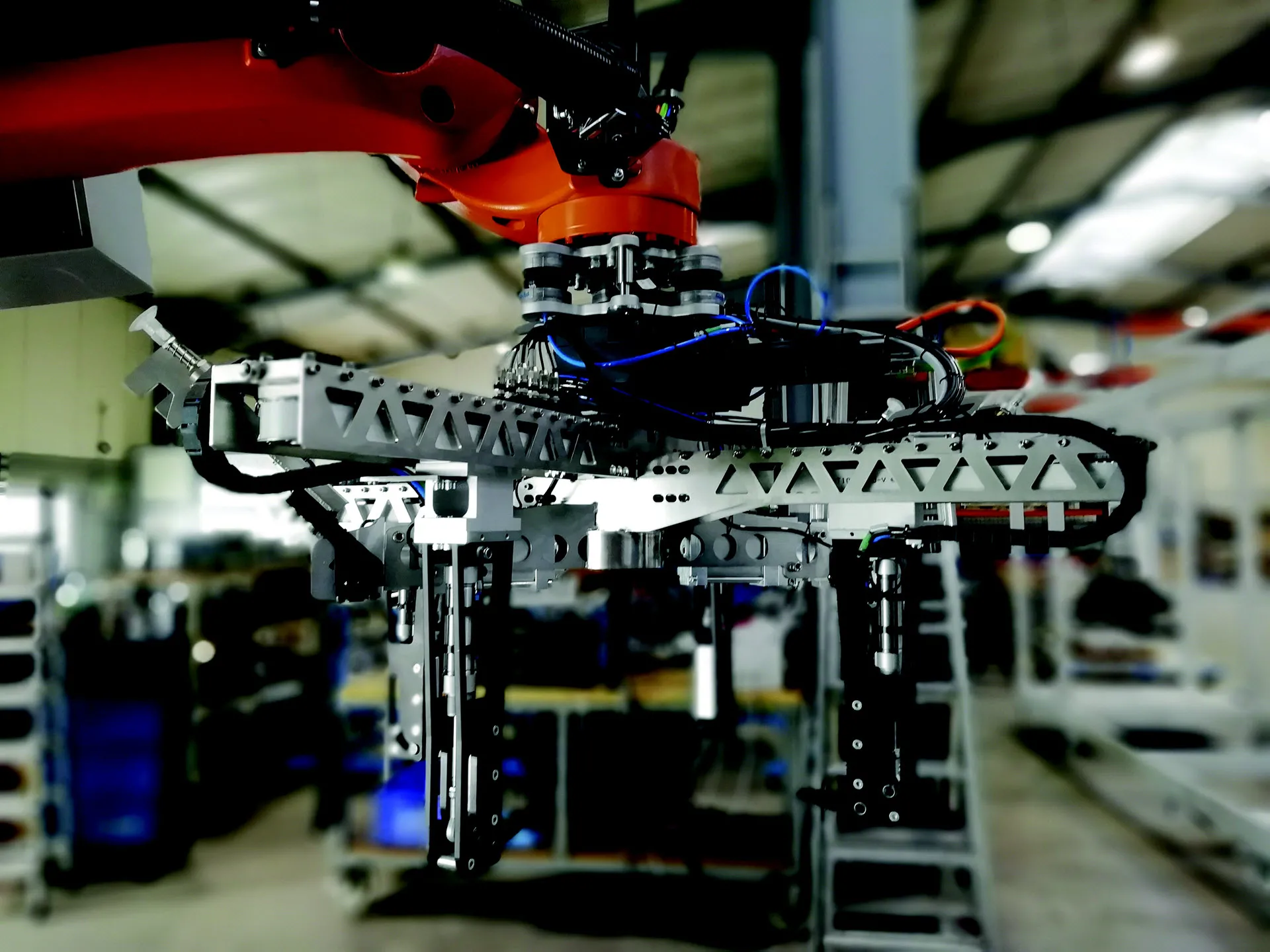

The German company develops and produces customized machines and automation systems for the automotive and manufacturing industries.

Challenge

To remain competitive and provide capacity for innovation, the company wanted to ensure that the engineering departments can deliver to the optimum level. Therefore, Horst Hoopmann needed to reduce the time spent on unproductive work – such as searching for existing components and revisions or requirements.

Solution

Horst Hoopmann adopted the 3DEXPERIENCE® platform including CATIA for 3D modelling. This solution enables working from a single data source. Everyone can create, store, version and release all 3D engineering data centrally. In the future, the company plans to expand use of the platform to project management and standard parts management.

Benefits

With all data in one place, instant access to up-to-date product and project information is available anytime to everyone. This makes data re-use easy, and engineers can now deliver more projects with high accuracy. This agile product development process leads to an increased completion rate with the same number of people, making the company more competitive.

Thanks to the platform, we can find components and revision levels faster, speed up new design work and complete more projects.

Horst Hoopmann

For more information: www.hoopmann-gmbh.com/en/

CCE Group

For more information: www.cce.de