EVUM MOTORS

EVUM Motors wanted to be first to market with its unique 4x4 electric utility vehicle. The start-up implemented the 3DEXPERIENCE platform to connect design, engineering and manufacturing, and deliver scalable access to digital design and simulation applications in a single, secure, standards-based environment.

A green, affordable utility vehicle for all

Capable of carrying heavy loads and off-road-driving, the aCar from EVUM Motors is a new breed of modular electric utility vehicle designed for the mobility needs of rural populations. More a small truck than a car, the idea for this robust, functional, affordable and green 4x4 was born at the Technical University of Munich (TU Munich) where a team of engineers set out to build a prototype electric vehicle for the African market. Their goal was to develop something that could be easily manufactured and financed in developing and emerging countries. It needed to be a simple, sustainable workhorse that could be built in close proximity to its customers, was low maintenance, ran on rugged terrains and could handle a variety of tasks, from transporting goods and people, to carrying hay and farming equipment.

The result was the aCar, an electric four-wheel drive with a range of up to 200km and a top speed of 70km/h, with a payload of 1,000kg. It’s powered by a 48V battery with solar panels on the roof to generate additional electricity, and a modular design makes it easy to outfit the aCar for different users, including tradesmen, vineyard workers and landscapers.

“The aCar is our contribution to making the world a little bit better,” said Martin Šoltés, a project manager on the aCar concept at TU Munich, now CEO and co-founder of EVUM Motors with Sascha Koberstaedt. “We emphasized a vehicle design that doesn’t just stick to one idea and enables local and environmentally friendly manufacturing in close proximity to our customers. It is our contribution to a more even distribution of the world’s prosperity and to integrating people in developing and emerging countries in the economic cycle. It’s such an important mission to us that we wanted this to be more than simply an idea; we want to industrialize it.”

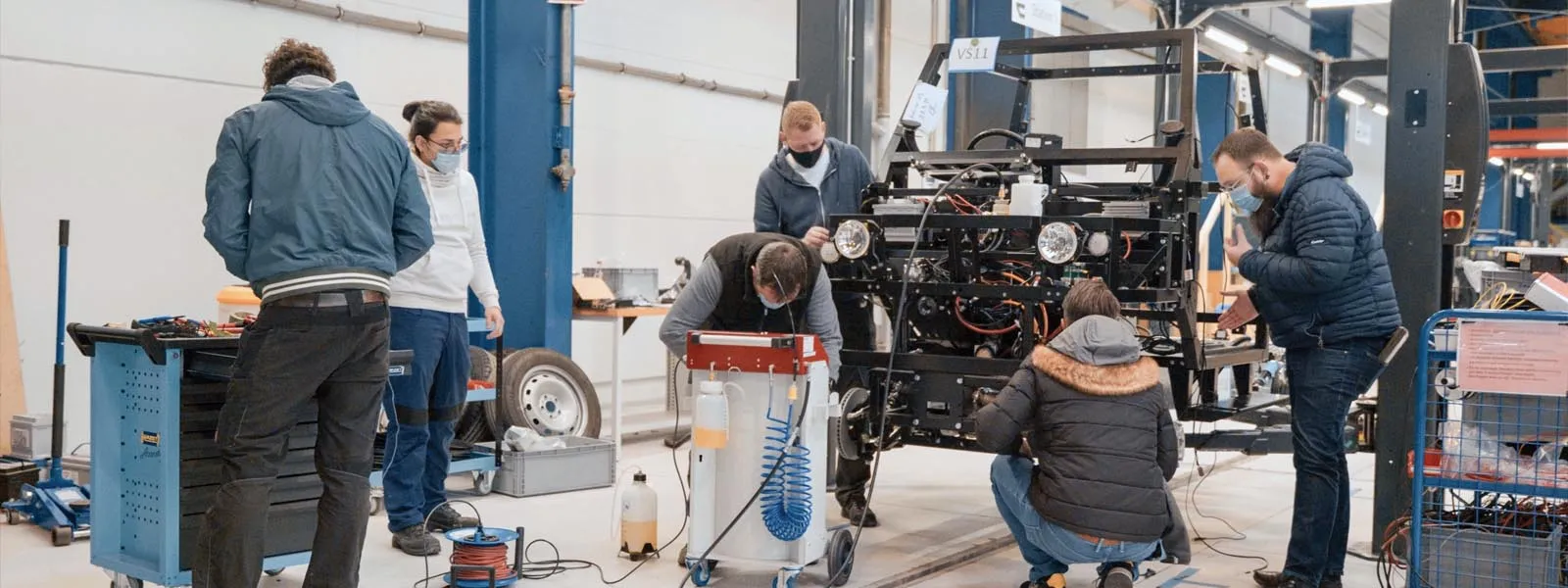

Today, EVUM Motors is bringing the aCar from concept to reality and gearing up to produce it on an industrial scale from its manufacturing facility in Bayerbach, Germany.

“The aCar is a sustainable mobility solution for everyone,” said Sascha Koberstaedt, CEO and co-founder of EVUM Motors. “A simple and economical innovation concept, it’s the future of electromobility in the transport sector. The aCar is both “back to roots” and “state of the art” at the same time. It’s simple, but takes advantage of the latest technology; and it’s intuitive, purpose-oriented and highly flexible in its possible uses. We’ve designed it so that it can run really efficiently on just 48V with a very long-lasting, resource-saving battery solution, and yet it can still climb the steepest of slopes. The aCar is a small, light muscle man that fits every budget and is also kind to the environment.”

There is a short window of time for entry into electromobility. You have to be quick with a reliable, full developed product on the market. 3DEXPERIENCE on cloud helps us to accelerate development.

Bringing the aCar to market

As EVUM Motors works fast to establish itself in the highly competitive EV industry and scales up production, it needed a technology platform to support its growing operations and accelerate its time to market. The team – many of which were involved in the initial project at TU Munich – were already familiar with the design application CATIA as they had used it at university, so it was a natural decision to opt for the 3DEXPERIENCE® platform on cloud.

“CATIA seems to be the easiest and most effective design solution,” Šoltés said. “It was one of the main tools taught at university, so we already had the advantage that we knew how to use the tool and we wanted to extend that functionality with the 3DEXPERIENCE platform.”

As a start-up, it was critical that EVUM Motors had access to enterprise-level technology and gain the full capabilities it needed to get off the ground quickly. It recognized that the cloud would help it move its vehicle from design to manufacturing at unprecedented speed and scale.

“There is a short window of time for entry into electromobility, which is receiving large and strong funding from the state,” Šoltés said. “You have to be quick with a reliable, full developed product on the market. The 3DEXPERIENCE platform on cloud helps us to quickly exchange the data and information required for accelerated development.”

EVUM Motors successfully worked with Dassault Systèmes business partner and 3DEXPERIENCE specialist CENIT on the implementation.

“When starting our business, we discussed our needs with CENIT who proposed the 3DEXPERIENCE platform as scalable and flexible solution,” Šoltés said. “They helped us transfer all data from our student licenses to business licenses and have supported us throughout. When we have a question or issue, CENIT is our first responder. They handled the implementation and, now that we’re up and running, we know that we can turn to them if we need additional licenses or training.”

Following successful tests in Germany and Ghana, and positive feedback at industry events, including the IAA 2019 International Motor Show in Frankfurt, EVUM Motors is initially selling the aCar to the European market. Here, demand for a multi-purpose, affordable EV is high among local trades.

“This product perfectly meets the market conditions in Germany and Europe for a simple, inexpensive electric utility vehicle,” Koberstaedt said. “Tradespeople from a wide variety of industries need a real workhorse, a robust vehicle. The sustainability aspect is important to them too as they look for a green vehicle that will reduce their carbon footprint. They also want it to help them save money in their day-to-day work and be assured of reliable support for this new, perhaps partly still unknown, technology.”

Entering new markets with the cloud

A cloud implementation was an ideal fit for EVUM Motors’ business needs on many levels. Not only does the 3DEXPERIENCE platform on cloud give it the agility and flexibility to scale up and down its computing resources in line with its business needs, it also is a future-proof solution that can adapt and grow with the business as it enters new markets and delivers on its philosophy “Engineered in Germany – reinvented everywhere.”

“We are a German company and our development work stands for high quality,” Šoltés said. “But outside of Europe, we want to create awareness for a culture of simple mobility solutions. We want to show that electromobility does not have to be expensive.”

The aCar’s simple and reliable design is key to enabling manufacturing with very low investment costs. In the near future, EVUM Motors plans to expand production into developing and emerging countries, manufacturing many of the vehicles’ components on location to build stronger local economies. As it sets up new manufacturing facilities worldwide, the company’s cloud-based platform will scale with the business and keep all facets connected.

“The cloud-based system can be used anywhere,” Šoltés said. “Because it’s not location based, it means that if we set up production in another country, everyone can work from any device on the same platform, regardless of country.”

As a start-up, it’s extremely important for us to be able to work quickly and efficiently.

EBOM and MBOM on one platform

CATIA is being used to design the aCar’s sheet metal parts and then incorporate component designs from outside suppliers to create each model. On cloud, the company is able to collaborate with external suppliers with ease and draw from unlimited computational power to run comprehensive preliminary studies and determine the best possible design.

“We’re using sheet metal parts for the car,” said Florian Liebl, head of the mechanical design team at EVUM Motors. “Using CATIA, we can design these sheet metal parts and combine those with files from assembly part suppliers. The best thing about the 3DEXPERIENCE platform is that a lot of people can work on the same assembly group at the same time.”

The company is also taking advantage of DELMIA to define the manufacturing bill of materials (MBOM) directly from the engineering bill of materials (EBOM) in CATIA, using design data to directly propagate downstream processes. This enables engineers to plan and validate production and gain real-time visibility of production performance and quality.

“It was important to choose DELMIA as it’s CATIA’s counterpart,” Liebl said. “We use DELMIA for process planning, time scheduling and, in future we will use it to create work instructions. Digital continuity is really important to us and it’s a huge benefit having everything on one platform, being able to go straight from the EBOM in CATIA to the MBOM.”

Not only is EVUM Motors using the 3DEXPERIENCE platform to design and engineer the aCar, it’s also using the technology to develop a 3D layout of its new production facility in Bayerbach, Germany – critical as the company moves from building each vehicle individually to developing a fully operational assembly line. By verifying processes using virtual simulation, it can optimize its assembly setup and identify any potential manufacturing issues in the 3D environment and correct them upfront, without a physical prototype. This will help to keep development costs down and avoid unnecessary waste.

“With a 3D layout of the production facility, we can simulate the production line and get a better understanding of our processes,” said Maximilian Negele, head of production at EVUM Motors. “We’re currently producing small batches of cars, but plan to scale up and produce 2,000 vehicles a year.”

Selling the vision

Early positive feedback at trade fairs has been a key factor in EVUM Motors’ rapid growth, as the industry recognizes the value of an affordable and accessible electric vehicle like the aCar. “There are some vehicles out there that have similar characteristics to the aCar, but they haven’t set out with the same objective as us in terms of simplicity,” Koberstaedt said. “With our modular approach, low voltage battery, solar panels mounted on the roof and extremely simple structure, which is very durable and robust, we have a vehicle that can be used in many places around the world, across many sectors.”

The company is now exploring how it can use virtual reality to share its vision with more potential customers worldwide.

“With the 3DEXPERIENCE platform you can develop realistic virtual experiences, for example a 3D configurator, and share these at trade fair appearances or in customer meetings and demonstrations without needing the physical vehicle,” Šoltés said. “We can also show new levels of development and showcase the latest improvements and design options in a really intuitive and immersive way.”

With the platform on cloud, the company now has a strong foundation to establish itself as a leading OEM in the light commercial vehicle market and grow its business globally.

“We’re creating awareness for a culture of simple mobility solutions,” Šoltés said. “We want to show the world that electromobility does not have to be so expensive and should be accessible to all.”

Focus on EVUM Motors

EVUM Motors is the spin-off of a visionary research project from the Technical University of Munich to develop a new kind of utility vehicle that is compact, fully electric and four-wheel drive. The industrialization of the aCar research project is the driving force behind EVUM Motors as it seeks to unite economy and ecology and bring to market the ideal electric vehicle for the agriculture, craft and industry, municipal work and recreational sectors.

For more information: www.evum-motors.com

Focus on CENIT

CENIT empowers sustainable digitalization. Our solutions are based on innovative technologies in product lifecycle management, the digital factory and enterprise information management. CENIT consultants provide customers with end-to-end advice to ensure that solutions are implemented with an understanding of the entire value chain. With a holistic approach and based on trusted partnerships, CENIT takes responsibility for solutions on behalf of our clients. CENIT has been helping prestigious customers in key industries to gain competitive advantages for over 30 years.

For more Information: http://www.cenit.com/