Elysian Aircraft

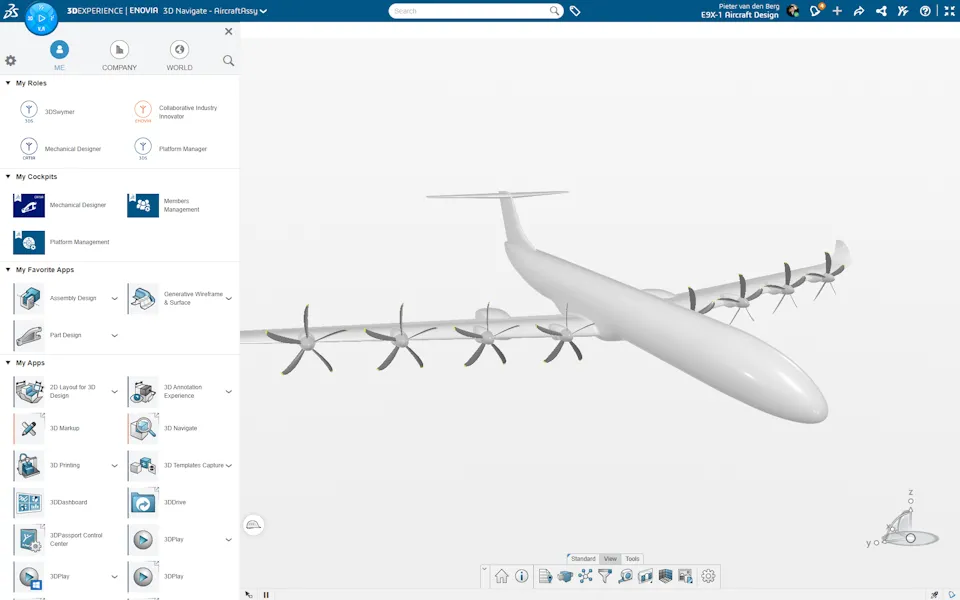

Elysian accelerates the design, testing, validation and certification of its 90-seat, zero-emission battery-electric passenger aircraft – the E9X – with the 3DEXPERIENCE platform on the cloud.

Reshaping Aviation With Viable Electric Aircraft Propulsion

Netherlands-based aerospace company Elysian Aircraft has a grand vision: to replace 50% of all scheduled flights worldwide with a zero-emission electric solution, ultimately enabling the industry to transition to electric-powered flight. To achieve its objective, the company is working on its flagship aircraft, the E9X. This 90‑seat, battery-powered aircraft can fly up to 800+ kilometers on a single charge.

“There’s currently no aircraft that can carry this many passengers such a distance using battery power,” said Daniel Rosen Jacobson, Elysian’s co-CEO, who founded the company alongside Reynard de Vries, the company’s chief engineer and Rob Wolleswinkel, co-CEO and chief technology officer.

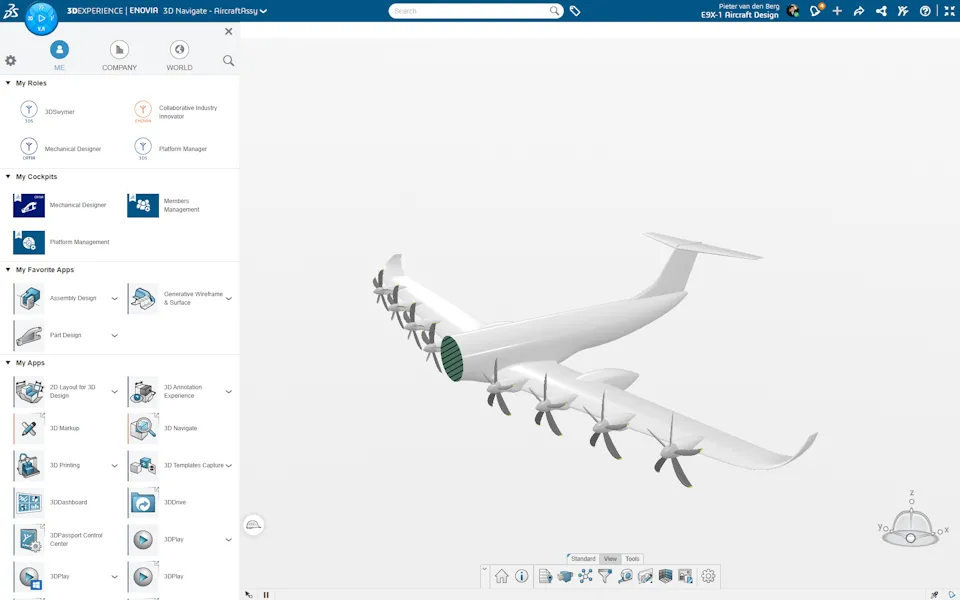

Together, Elysian’s founders are confident their vision will become reality. Their conviction comes from rigorous research and detailed calculations where they overturned long-held assumptions that battery-electric passenger planes could only be small, fly short distances, rely on future battery breakthroughs and must follow conventional aircraft layouts. Their calculations demonstrated that a 90-passenger aircraft is feasible with current or near-future battery technology and that 800+ km range is achievable with careful design – reconfiguring wings, fuselage and battery placement, for example – to improve energy efficiency and aerodynamics.

“What makes us different is that we’re not waiting for future technology breakthroughs,” Jacobson said. “Our solution relies on battery technology that already exists. With today’s batteries, we can already fly 500 kilometers. With steady improvements, we’ll reach 800 kilometers at entry into service.”

Elysian's research convinced key professors at Delft University of Technology (TU Delft) to get involved. Together, they co-authored two scientific papers that set out the visionary thinking and laid the foundation for the E9X.

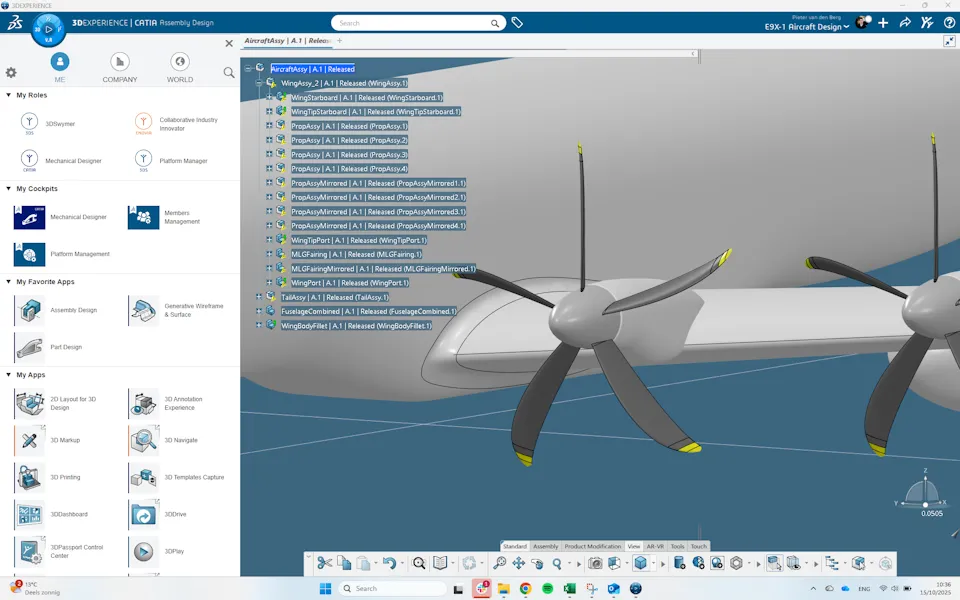

At this point, it was time to develop the first conceptual designs and bring the vision to life. For this, Elysian adopted Dassault Systèmes’ 3DEXPERIENCE platform on the cloud.

"We chose the 3DEXPERIENCE platform because it offers a robust, integrated suite of tools for CAD and product lifecycle management," de Vries said. “Many of our team members have prior experience with Dassault Systèmes solutions, which helped us adopt the platform quickly."

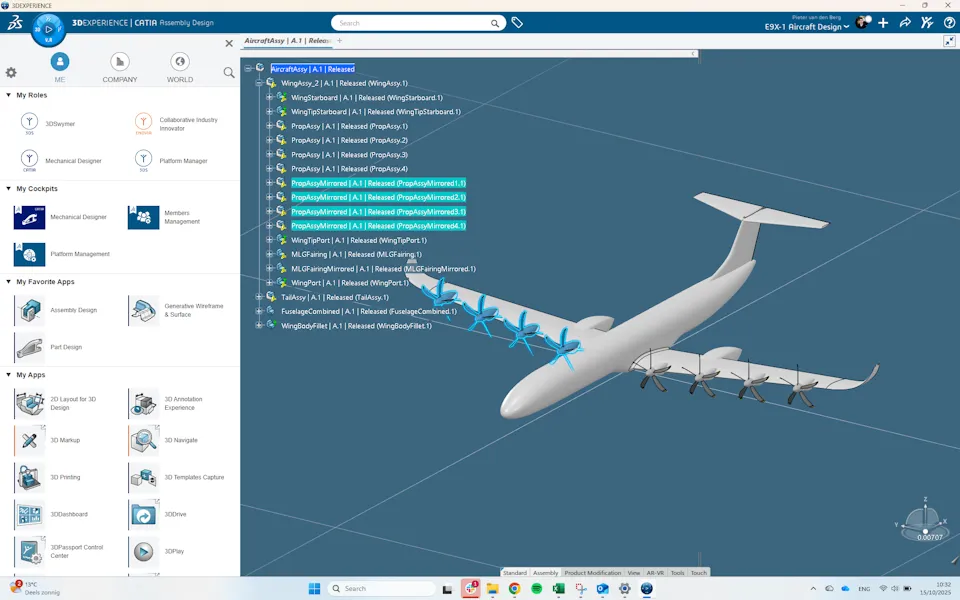

Elysian started from scratch on the 3DEXPERIENCE platform. Connecting design, analysis, systems engineering and data management, the platform also enabled Elysian to seamlessly integrate its existing third-party tools.

"As a new aircraft programme, we built our data structures, workflows and modeling approach directly within the 3DEXPERIENCE platform, rather than migrating existing content or following legacy templates," de Vries said. "While the aircraft design itself builds on years of conceptual work, our product lifecycle management and CAD environment within the platform has been developed from the ground up to fit Elysian’s needs."

Elysian Aircraft is designing its all-electric E9X using Dassault Systèmes’ 3DEXPERIENCE platform. The virtual twin enables engineers to optimize performance, safety, and efficiency for zero-emission flight.

Developing Electric Passenger Planes Using Digital Technologies

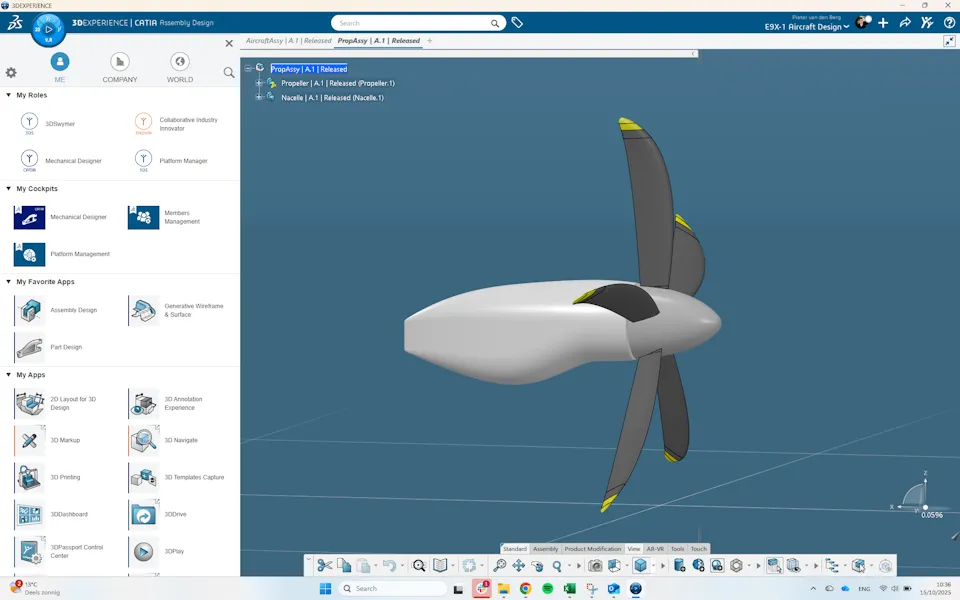

Multiple technical challenges must be resolved when developing a passenger aircraft with an electric propulsion system. These include battery cell integration, thermal management, reserve energy system design and high voltage power transmission.

The 3DEXPERIENCE platform not only helps Elysian’s team to design an electric airplane that overcomes these challenges, but also to simulate, test and then refine their ideas.

“There are different ways in which Dassault Systèmes’ solution helps us,” said de Vries. “We use it to design the aircraft, but also to take lessons learned from both digital simulation and physical hardware testing and bring them back into the design process, getting that data into the single source of truth.”

Rigorous digital testing, for example, has been crucial in helping Elysian tackle technological challenges.

“As we develop next-generation clean aircraft technologies, we need to virtually test new components, such as batteries for electric motors and the power distribution system,” de Vries said. “We then integrate those simulated components into a virtual twin, which lets us evaluate the entire aircraft as a whole.”

We use [Dassault Systèmes' solution] to design the aircraft, but also to take lessons learned from both digital simulation and physical hardware testing and bring them back into the design process – getting that data into the single source of truth.

By using simulation in the context of a virtual twin, Elysian can optimize the design of its aircraft. To achieve the ideal battery composition, for example, it can simulate the performance of different materials and assess the impact of key safety features like failure modes. It can also virtually test battery performance under varying temperatures, charging cycles and discharge rates to maximize energy density, lifespan and reliability. This approach reduces material waste, cuts development times and minimizes costs.

The result is a higher efficiency aircraft with a multitude of optimized design features. By placing batteries in the wing to lighten the fuselage, for example, Elysian’s engineers are reinventing the complete passenger experience to fit with their future needs. The combination of larger wings and a smaller body (compared to a conventional aircraft) substantially increase aerodynamic efficiency. Meanwhile, using a gas-turbine-based reserve energy system provides energy to the batteries and motors in situations where the aircraft may need to remain airborne for longer than expected – when diverted, or awaiting clearance to land at airports, for example.

Soaring into a cleaner future — the Elysian E9X demonstrates the potential of all-electric, zero-emission flight.

Demonstrating The E9X's Compliance With a Virtual Twin

Elysian’s next challenge is certification. The company has already begun working with the European Union Aviation Safety Agency (EASA) to demonstrate that its aircraft meets performance, airworthiness and safety standards and has plans to involve the Federal Aviation Administration (FAA) at a later stage. To make this ride smoother, the company is using Dassault Systèmes’ virtual twin capabilities to integrate subsystem simulations and performance models.

“The virtual twin is key to evaluating and improving the aircraft, not just for design, but also for certification to demonstrate compliance,” de Vries said.

Elysian has now begun finalizing its second conceptual design and is moving into the preliminary design phase. Gaining traction within the global ecosystem, Elysian is collaborating with the wider aviation industry including airline companies to explore the technological and operational aspects necessary to deploy the E9X. This includes working out how maintenance and operational procedures may differ from conventional aircraft, and establishing which destinations are operationally and economically viable for electric flight.

Elysian expects the E9X to enter service in the next decade. As the company advances on its journey, Dassault Systèmes will remain a trusted partner.

“To build world’s first large-scale battery-electric aircraft, we need tools and partners that match our pace and standards for rigor,” Jacobson said. “Dassault Systèmes has been very helpful from the beginning. They’ve helped us gradually build our 3D modeling and product management systems. As we grow, more of their applications will be relevant to us. It’s a partnership we see continuing long-term.”

For de Vries, this is just the start of an incredibly exciting future that has the potential to not only shape the passenger experience of the future, but make flying more enjoyable, efficient and environmentally friendly.

“When we’re motivated, humans can achieve incredible things,” de Vries concluded. “Climate urgency means we must make aviation more sustainable. It’s exciting to help make that a reality.”

Discover more about the Co-Design to Target and the Program Excellence industry solution experiences.

Focus on Elysian Aircraft

Founded in 2023 after two years of research, Elysian is redefining air travel with a large-scale, zero-emission aircraft. Led by a team of experienced aerospace engineers, aviation experts and venture builders, Elysian is building battery-electric technology that offers a commercially competitive solution for decarbonizing aviation.

For more information: https://elysianaircraft.com/