CSSC Huangpu Wenchong Shipbuilding Corporation Co., LTD

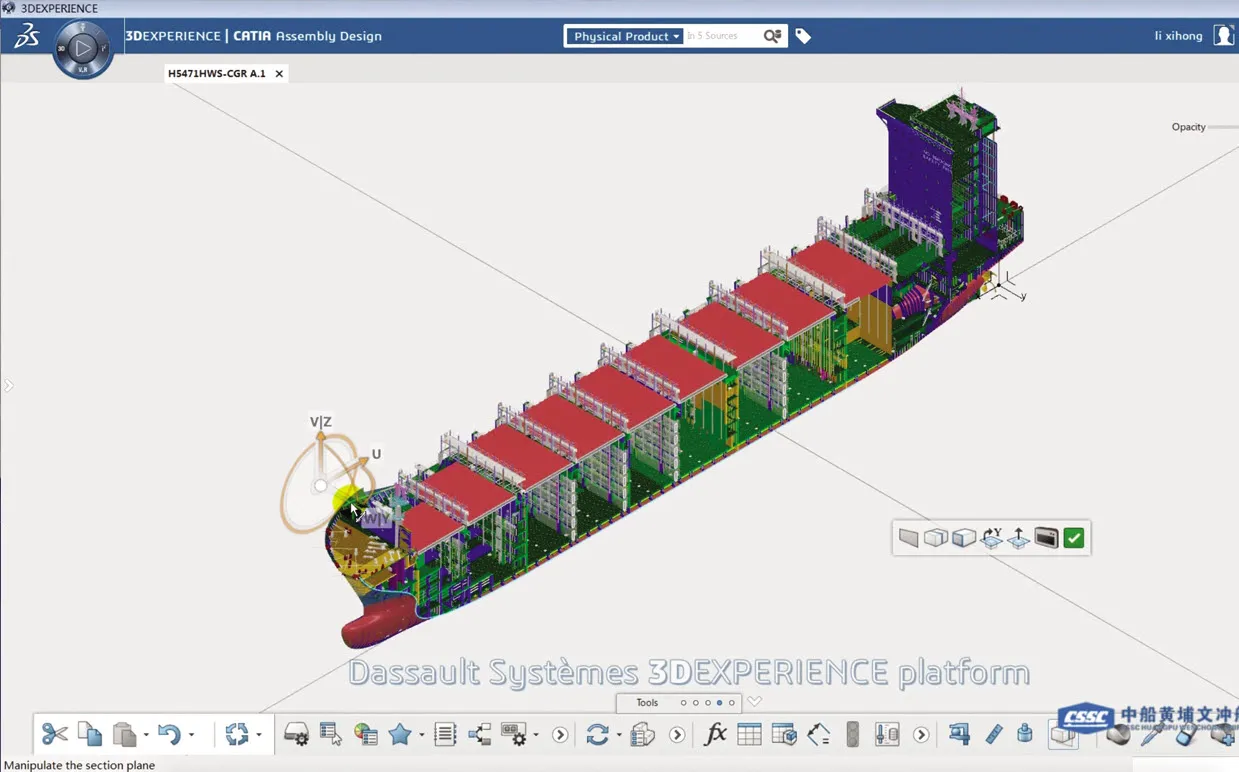

The company chose Dassault Systèmes’ 3DEXPERIENCE platform and its Designed For Sea and Optimized Production For Sea industry solution experiences for design and manufacturing planning.

Shipbuilding company moves forward with technology

Huangpu Wenchong is a subsidiary of the China State Shipbuilding Corporation (CSSC) and one of the largest shipyards building military and commercial cargo ships. The slowdown in the world’s economy has had a dramatic effect on the shipping industry. New ship orders are sluggish for China’s shipyards and Huangpu Wenchong is feeling the effects of this situation. “Our company faces a decline in new ship orders and persistently high shipbuilding costs that are challenging our competitiveness,” Zhongqian Chen, CEO of Huangpu Wenchong Shipyard said. “To improve our productivity and reduce our costs, we decided to deploy a shipbuilding management solution that combines design, management and production in one integrated environment. This environment is Dassault Systèmes’ 3DEXPERIENCE® platform,” he said.

“In the past, our company used hundreds of disparate and disconnected software for design, production and project management resulting in information silos,” Xihong Li, deputy chief engineer at Huangpu Wenchong, commented. “The 3DEXPERIENCE platform provides a single data source on which all processes are based, thereby enabling us to eliminate problems that have been troubling us for a long time such as incompatible data and data conversion issues. We can seamlessly combine design, manufacturing, and project management into an organic whole so that ship development can be managed and controlled in real-time,” he said.

Seeking design and manufacturing excellence

Huangpu Wenchong adopted the 3DEXPERIENCE platform’s marine and offshore industry solution experiences Designed For Sea for ship design and Optimized Production For Sea for manufacturing design and planning. “Designed For Sea provides us with a seamless solution for conceptual design, detail design and production design,” Li said. With Optimized Production For Sea, Huangpu Wenchong is tackling key production activities such as manufacturing assembly definition, discipline-related work preparation, process planning and the generation of 3D interactive work instructions to help optimize production. Moreover, the company benefits from seamless integration between engineering and manufacturing and can simulate and validate the build process before execution begins, which helps mitigate unforeseen, last-minute issues.

“We have restructured our design and building processes on the basis of the 3DEXPERIENCE platform,” said Xiaofeng Zou, director of Huangpu Wenchong’s technical center. “For example, we address ergonomics issues by simulating equipment repair in a digital environment, which enables us to account for the space needed to access the work area in our designs. This improves their quality and confirms maintenance feasibility early on in our development process.” Moreover, rules and specifications are entered into the system, which helps ensure they are taken into account throughout the design process. “We can configure our company rules and control our designs as we go along, thereby improving design compliance with company standards,” Zou said. “Complying with preconfigured rules throughout the design process facilitates downstream certification because regulations were already designed for,” he added.

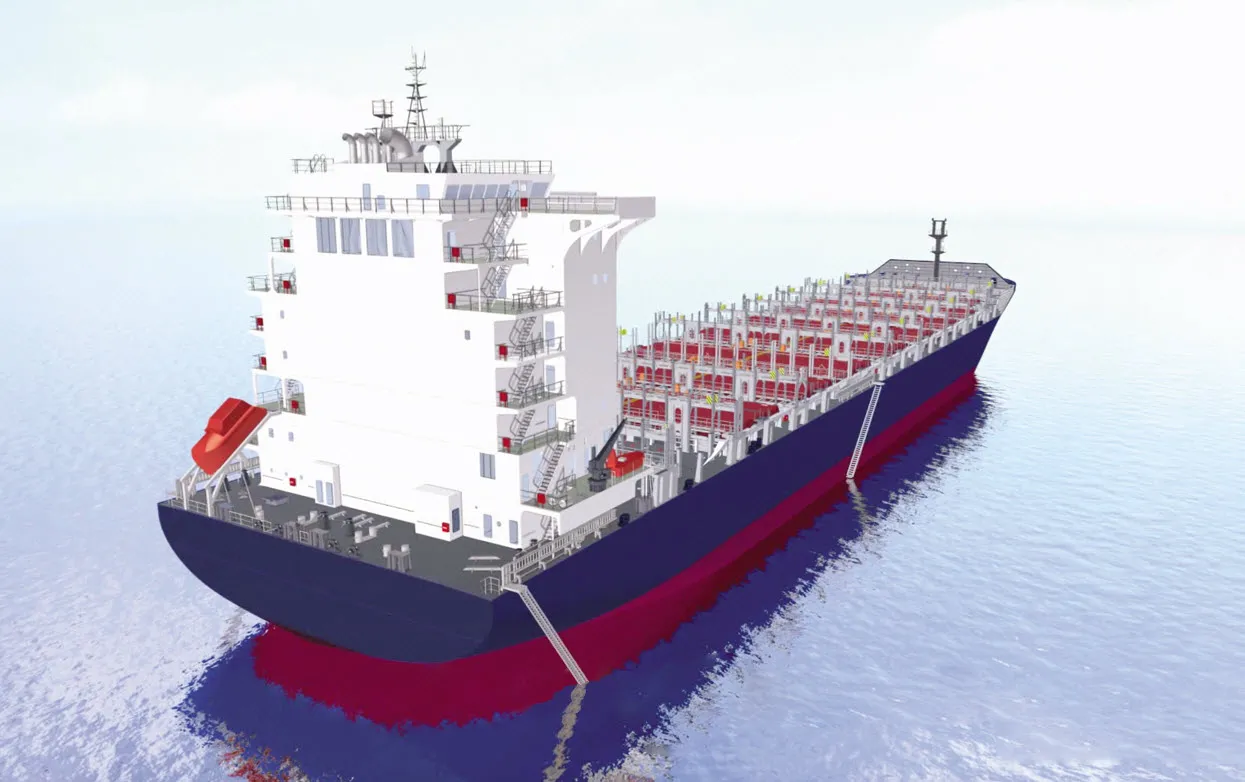

Among the 2,700 TEU container ship programs that Huangpu Wenchong Shipyard started in September 2016, more than 100 designers involved in these programs use Designed For Sea for their activities. “More specifically, Designed For Sea is used to build technology libraries, partition cabinets, and model four major disciplines that include the ship’s structure, machinery, electronics, and equipment,” Li said. “Digital models are produced and every aspect of the design is reviewed. The designers then develop an optimized manufacturing process and produce data that can be directly fed into our CNC machines to perform digitally-controlled operations like cutting a plate or bending an elbow pipe.”

“We also design the electrical and fluidic systems of the ship in parallel, enabling the workers in these disciplines to work together with our structural engineers,” Zou said. “This concurrent collaborative approach helps avoid late-stage errors that can jeopardize schedules and budgets. Designing with an integrated platform and a single data source allows process control from a management perspective. We also use templates to accelerate design time, digitally simulate the build process, and demonstrate the ship to the customer to collect their comments and changes before finalizing the design,” Zou said.

To improve our productivity, we deployed a shipbuilding management solution that combines design, management and production in one integrated environment. This environment is Dassault Systèmes’ 3DEXPERIENCE platform.

Faster customization and response to ship owners

“China’s shipbuilding sector has an increasingly high demand for customization,” Li added. “During design reviews, we may need to make modifications and changes to meet the specific demands of ship owners. From a design perspective, this requires us to implement these changes in a timely manner while ensuring design quality at all times. With Designed For Sea, we can quickly incorporate any modification and provide customers with an immersive experience of their ship. From a manufacturing perspective, additional requirements require us to verify a design’s manufacturability as well. Working in an integrated digital environment accelerates the process,” he said.

“All in all, the largest value brought on by the 3DEXPERIENCE platform is the integration of the design and manufacturing processes and the ability to see how one affects the other,” Li explained. “Our goal is to implement a smart manufacturing platform at our company and to adopt additional Dassault Systèmes’ solutions in the future to further improve the quality of our designs and the efficiency of our build process,” he said. “The technology advancements and innovations of the past few years are the driving force behind Huangpu Wenchong’s growth. The 3DEXPERIENCE platform is a key enabler of our development,” Chen concluded.

Focus on Huangpu Wenchong

Shipbuilding company operating in the People’s Republic of China.

Products: container feeder, dredging engineering vessels, drilling platform, drilling ships, and large offshore support vessels for ocean engineering.

Employees: 6,000

Headquarters: Guangzhou, China

For more information: gws.cssc.net.cn/cms_gzwccc_en/