CHANGJIANG DESIGN GROUP CO., LTD

Full-service provider CDG implemented the 3DEXPERIENCE platform to connect all disciplines and handle the entire building lifecycle of its water conservancy and hydropower projects in an integrated 3D data application environment.

Entering the age of smart hydropower

On the Jinsha River, between Southwest China’s Yunnan Province and Sichuan Province, lies one of the tallest and most technologically advanced mega hydropower stations in the world. Engineered by CDG, the Wudongde Hydropower Station dam stands at 270-meters high and takes advantage of cutting-edge technologies to run more efficiently and safely. This includes real-time temperature monitoring, low heat cement and an intelligent water flow system that can be adjusted to cool the 2.8 million cubic meters of concrete and prevent cracking. Everything about this hydropower station was built from the ground up to be innovative, starting with the engineering survey and design processes – all handled using the power of the 3DEXPERIENCE® platform.

Making the transition to efficient 3D design and complete product lifecycle management technology is central to CDG’s vision to transform the way it designs and develops new water conservancy and hydropower projects, and manages the ongoing maintenance of infrastructures.

“We need to rapidly transform our development so that we can distinguish ourselves in the market while protecting the eco-environment,” said Xiaomao Wang, chief engineer at CDG. “Currently, our top task is to expand our growth space by digitally transforming ourselves. We’re doing this by digitalizing our traditional businesses, and then combining and integrating it with big data, cloud, internet of things (IoT), mobile IoT and 5G technologies to improve the quality of our products.”

A new approach for Wudongde

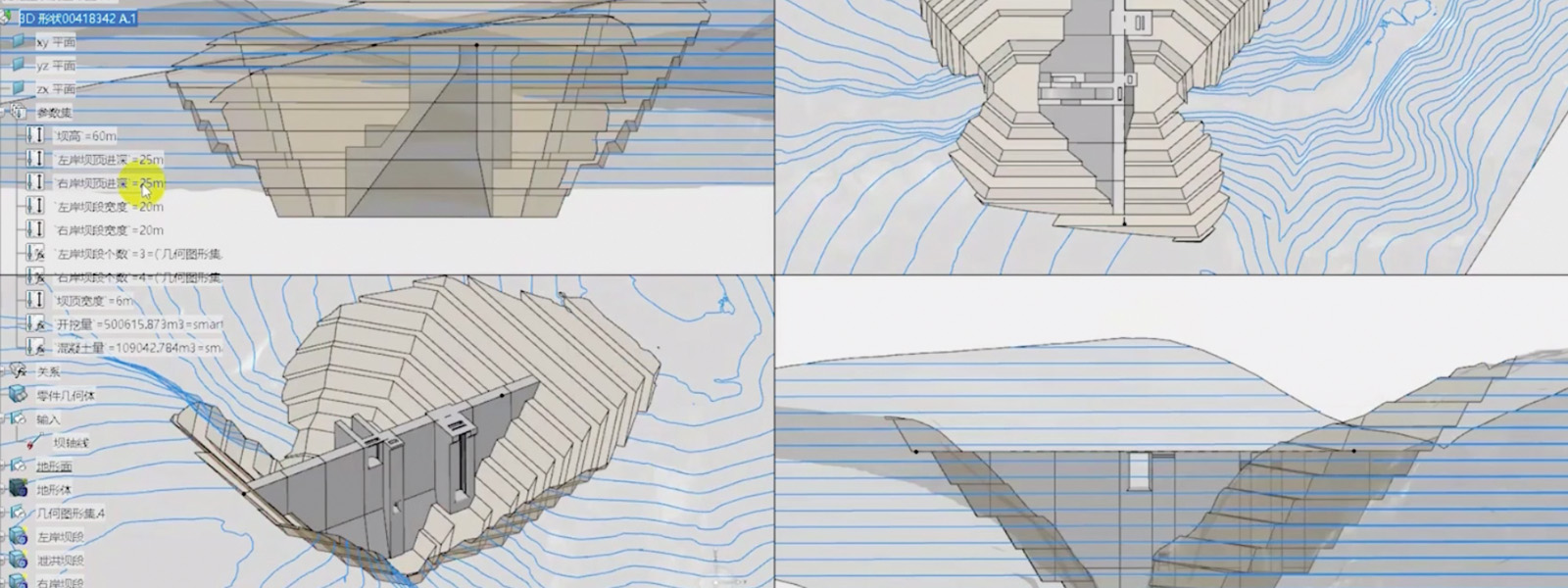

CDG implemented the 3DEXPERIENCE platform to solve two major challenges: to modernize its manual, 2D design processes and integrate a multitude of disciplines and working practices on one platform to pool information, improve collaboration and boost quality.

“We needed a platform for collaborative design, so that we could streamline the business architectures and processes traditionally used in water conservancy and the hydropower industry,” Wang said.

CDG migrated its business processes to the 3DEXPERIENCE platform in phases.

“We chose the 3DEXPERIENCE platform to assist our current project with some on-site design work, so that we can gradually shift our conventional 2D design to 3D to improve efficiency,” said Min Feng, director of the BIM Center Hydro Junction Department at CDG. “Secondly, we wanted to improve our overall design quality and expand the scope of services we offer and data we use. We’re now using the platform as a 3D BIM tool for design, operations and maintenance work.”

As it modernized its approach, CDG began exploring the 3DEXPERIENCE platform’s capabilities and applying them to new projects, including the Wudongde Hydropower Station.

“We’ve been using the platform for our feasibility study stage,” Feng said. “It began in 2016, as a pilot navigation project and then in 2017, we used the 3DEXPERIENCE platform to build the architecture and template library for the Wudongde Hydropower Station and Xulong Hydropower Station.”

CDG worked with Dassault Systèmes’ business partner Shanghai Jiangda Technology to implement the 3DEXPERIENCE platform.

“We worked closely with the team there to determine which tools best suited our business needs,” Wang said. “We are committed to becoming advanced 3D technology users and they helped us fully embrace the 3DEXPERIENCE platform and take the steps to realizing our long-term vision.

The 3DEXPERIENCE platform is a very powerful and open platform. It unifies and coordinates the different disciplines.

Uniting project management

Successfully managing large-scale projects like the Wudongde Hydropower Station involves bringing together multiple disciplines and industries – something which has been a challenge for CDG as it widens the scope of projects and services it delivers.

“For water conservancy and hydropower projects, the professional scope involved is very wide ranging, including dams, factories and so on,” said Shangfa Chen, director of the R&D center at CDG. “There are many buildings and disciplines involved.”

With ENOVIA on the 3DEXPERIENCE platform, CDG can bring all project facets together in one place and streamline its processes.

“The 3DEXPERIENCE platform is a very powerful and open platform,” Chen said. “It unifies and coordinates the different disciplines involved and empowers us to use information more effectively. It gives us access to a single data source to achieve collaborative design and gain a complete view of the entire lifecycle, from planning, survey and design, to construction, operation and management.”

The platform also helps CDG tackle complexity by establishing a common working template for new projects and capturing all data created in the process to inform future projects, and plan next stages such as building and maintenance.

“For our water conservancy and hydropower projects, the mechanical, electrical and metal structural equipment involved in these structures is very complex and must take into account topographic and geological conditions,” Chen said. “Different industries define their own professional requirements on the 3DEXPERIENCE platform to establish a template suitable for their own discipline, which can then be integrated into the overall project. We collect all of this different information and create knowledge libraries. We can then reuse all parametric templates and component libraries.”

Importantly, the 3DEXPERIENCE platform provides all the functionality required to manage an entire project.

“We’ve mainly used ENOVIA and DELMIA on the Wudongde and Xulong projects and other large constructions,” Feng explained. “We use DELMIA to simulate the construction of arch dams. ENOVIA helps us keep our projects on track, plan resources and draw up a cost plan. We used the BIM capabilities on disciplines so they could collaborate in real time and refer to each other’s ongoing work. As each stage is completed, we’ve been able to easily release data to the teams at the same time to improve communication.”

This saves the engineers at CDG time going between different applications, and converting data into different geometry types and formats.

“We no longer need to shift between different software,” Feng said. “Previously, we needed to triangulate geology surfaces, but now we can select what we want to see according to terrain and geology without triangulation, making it more intuitive and much simpler.”

CDG manages all of its project planning, work breakdown structure, collaborative design, 3D review and relevant downstream services with the project management applications of ENOVIA.

“It is completely consistent with the concept of modern project management,” Chen said. “ENOVIA’s functions, based on single- or multi-project, can be organically unified with the project management in our entire development and design unit.”

Speeding up with 3D design

Making the transition from handling its engineering survey and design processes in 2D to 3D has been nothing short of transformational for CDG.

“The design ideas are completely different,” Chen said. “One is flat and the other is full 3D. In the past, when we had a design briefing after the design results were submitted, it was difficult to communicate what we had done. We had to repeatedly explain the abstract design blueprint to the construction owner. Now, it is much simpler to communicate with them because there is a 3D model. It is very intuitive and visual, so it can be understood quickly after a simple introduction.”

This new approach is also saving engineers significant time as they design new assets.

“Once the 3DEXPERIENCE platform was deployed, our design cycle began to shorten significantly,” Wang said. “For example, one of our generic designs might take one and a half months to complete in the past, but now usually takes only 10 days. We recently had to design more than a dozen outlet pump houses and all design drawings had to be delivered within three months. Working on the 3DEXPERIENCE platform, we finished all 11 projects within 40 days.”

The 3DEXPERIENCE platform is changing our design thinking. It means that we can complete future jobs faster, more efficiently, to the highest possible quality.

Building smarter with BIM

Because every detail of a new construction is modelled using BIM on the 3DEXPERIENCE platform, CDG can explore design options in CATIA and easily make changes without impacting quality, delivery times or cost.

“It is especially difficult to make changes to 2D designs, which can lead to mistakes, leaks and clashes,” Chen said. “With 3D design, everything is under this model, and any problems can be discovered at a glance. Design results can be simulated in both the design and construction stages. Through the simulation, we can fix problems before they impact construction. This offers huge benefits in terms of improving our overall design and construction quality.”

The 3D BIM connects all facets of the entire project lifecycle to inform future stages and generate all documentation for construction.

“Design isn’t simply a matter of making a drawing and submitting it,” Chen explained. “Backed by the 3DEXPERIENCE platform, the whole design process is forward thinking, considering build, operation and maintenance. It is systematic.”

This new approach is transforming the way CDG tackles new projects, allowing teams to work on designs and engineering concurrently and plan ahead.

“The 3DEXPERIENCE platform is changing our design thinking,” Feng said. “Now, every discipline is involved on the platform, and we’re thinking about designs in parallel. We can carry out topography mapping, create engineering drawings, measure engineering quantity and analyze simulation calculations far more conveniently, streamlining our entire design process. It means that we can complete future jobs faster, more efficiently, to the highest possible quality.”

For example, CDG can now simulate construction to inform planning and resourcing, and ensure all processes are viable.

“The equipment used in the previous design may not be completely consistent with the construction equipment available,” Chen said. “After the design results are provided, we can immediately simulate actual construction machines, tools and equipment. All of this is very intuitive and objective, and fully reflects the value of the 3DEXPERIENCE platform.”

Progressive design thinking

Now, the company is looking for other areas in which it can further explore the full value of a BIM approach.

“We need to learn how to collaborate design and computation and how to enable interactions between our lightweight models on the 3DEXPERIENCE platform so that we can achieve more important breakthroughs for resource savings and utilization,” Wang said. “These areas will become the strongest growth points for the application of BIM technology in future.”

Focus on CDG

Changjiang Design Group Co., Ltd (CDG), affiliated to the Changjiang (Yangtze River) Water Resources Commission, Ministry of Water Resources, is a state-owned technologybased firm and international contractor. The company is one of leading water and hydropower project survey and design firms in China, top 20 ENR engineering design firms in China, top 100 survey and design institutions in China and top 500 technology innovation companies in China. CDG is a state high-tech firm, with high class qualifications, such as Integrated Class-A Qualification of Engineering Design, Integrated Class-A Qualification of Engineering Survey and Integrated Class-A Engineering Consulting, as well as qualification for contracting aboard. It is also running nearly 10 top-class development platforms such as national dam safety engineering technology research center, postdoctoral research center and fellow-level expert research center.

For more information: www.cispdr.com

Focus on Shanghai Jiangda Technology

Established in 1997, Shanghai Jiangda Technology is a hi-tech company focused on providing product lifecycle management and enterprise solutions to different industry clients. The company has helped more than 600 businesses take advantage of Dassault Systèmes software, covering a variety of industries including transportation and mobility, marine and offshore, industrial equipment, aerospace and defense, hi-tech electronics and life sciences and healthcare.