BOXXCRAFT

BOXXCRAFT uses the 3DEXPERIENCE platform on Cloud, including xGenerative Design, xDesign, xShape and 3D Markup, to create 3D virtual models from the knowledge and know-how of craftspeople with anytime, anywhere access.

Bespoke craftsmanship

From his garage to a small industrial building in Long Island, New York, carpenter and owner of Eyebrow Window Dormer Supply (EWDS) Michael Cunningham makes custom eyebrow window dormers for houses. These beautiful arching roof structures, designed to break up a straight roofline, take many hours to design and construct by hand. Cunningham creates each one individually, calculating the exact measurements before building the complex structure and delivering it to be installed on site.

Learning how to make eyebrow window dormers has been a labor of love for Cunningham. “Creating them takes a lot of trial and error, drawing many 2D images to figure out what angle works best to make the sweeping valley,” Cunningham said. “I then would have to measure each piece and create templates to get the roof pitches to match together and make the beautiful arch. If I got it wrong, I’d have to redo it until it looked right.”

One of the major challenges Cunningham faced over the years was convincing architects and builders that he could create such a complex, custom product off site and guarantee complete accuracy.

“The architects and builders who would want these products, they had a hard time accepting the fact that you can actually make these kinds of roofs off site and that they’ll fit,” Cunningham said. “I had to reassure them and give them certainty that I could deliver a perfect dormer that would fit seamlessly on the house.”

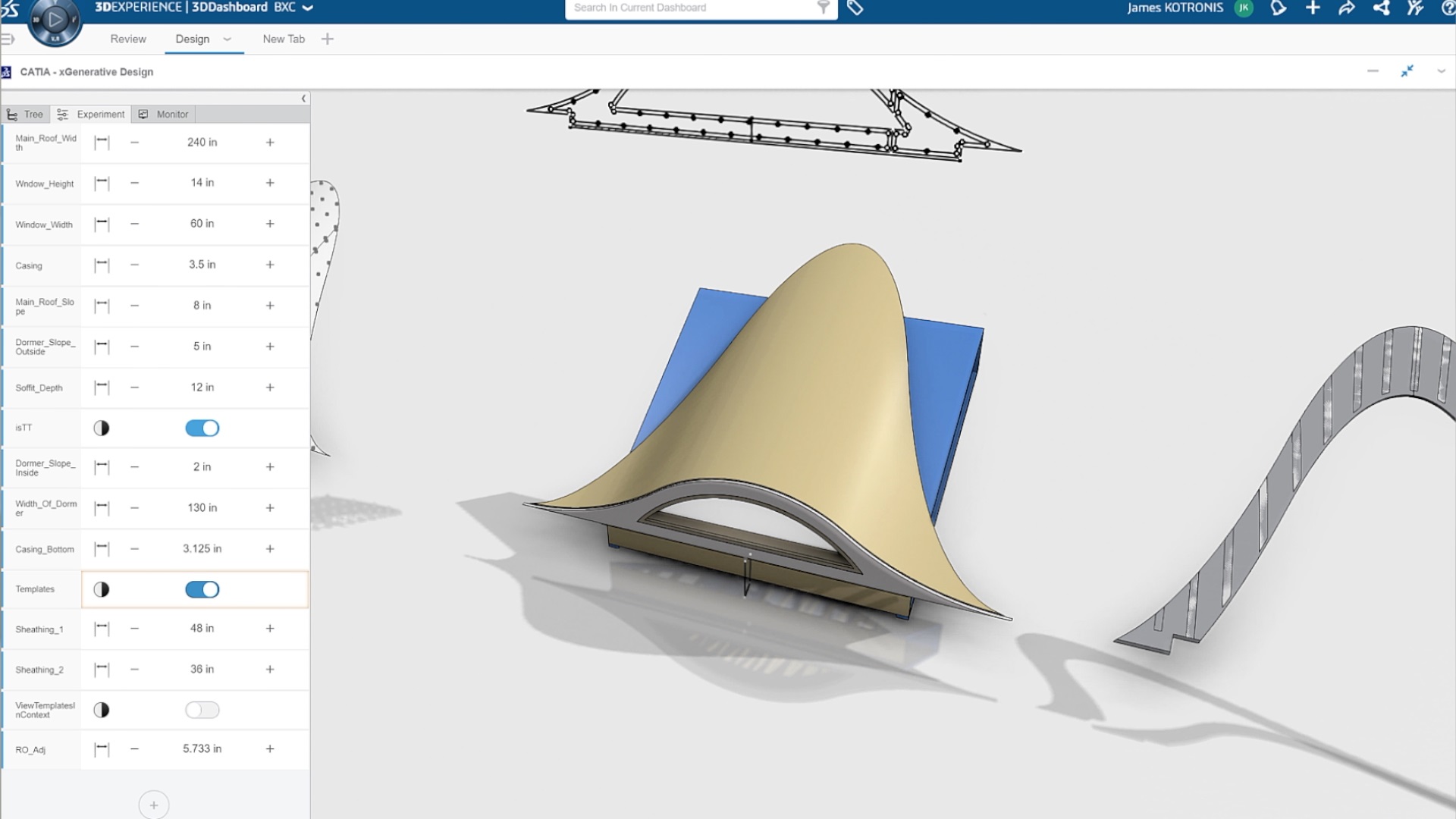

A brief discussion on a construction site with building delivery consultant James Kotronis set Cunningham on an exciting path to transform his design approach for the better. Kotronis is a longterm user of Dassault Systèmes design technology and shared the potential of the 3DEXPERIENCE® platform on Cloud to carry out all the 3D virtual modeling and calculations for EWDS.

“Within about five minutes he did a 3D model of a shape that would have taken me hours to draw out, using swinging tapes as a compass to find my points of tangency and to create an arch,” Cunningham recalled. “I thought it’d be great if we could make this into a tool.”

Today, the 3DEXPERIENCE platform on Cloud underpins the premise behind a new web app and company founded by the two businessmen called BOXXCRAFT. The BOXXCRAFT app not only powers the design process at EWDS but aims to help other craftspeople in the industry modernize and scale their businesses.

“BOXXCRAFT was founded to help suppliers thrive in the construction industry where the market is about to undergo what we believe will be profound changes,” said co-founder Kotronis. “What those changes will be is a transfer from what was prefabrication to manufacturing on a project-by-project basis to a product basis.”

The advantage of the technology is that within a standard budget, you can achieve a much higher quality product.

Accessible enterprise-level apps

Using the 3DEXPERIENCE platform on Cloud, BOXXCRAFT is able to bring sophisticated design tools to smaller-scale businesses and empower them to grow.

“You wouldn’t usually have access to this type of technology as a small craft carpenter,” Kotronis said. “You just couldn’t dive into this type of manufacturing technology. And so the cloud allows us to provide scalable solutions that companies such as Eyebrow Window Dormer Supply can access. They can take advantage of all this power without having to invest in massive servers and workstations and they can reap the benefits straight away as it is all there and ready for them to use. And because it’s on the cloud, it can scale with them.”

Kotronis believes that BOXXCRAFT and the 3DEXPERIENCE platform will help businesses like EWDS create custom products on a much larger scale and reach a wider audience.

“There’s a big difference between selling an individual solution and being able to sell it a hundred times over,” Kotronis said. “We believe that we can allow companies like Eyebrow Window Dormer Supply to access a much larger market.”

Kotronis champions web applications on the 3DEXPERIENCE platform, including xGenerative Design, 3D Markup, xDesign and xShape which can be used on-the-go.

“Now I can have anytime anywhere access to controls and powerful tools that are offered in the 3DEXPERIENCE platform, and that takes my experience and the way I interact with data into a whole new dimension,” Kotronis said. “It gives unprecedented access to powerful 3D tools that aren’t just able to provide an image but provide real information so that you can change the geometry actively on a tablet or any device.”

Saving time and costs

Today, the BOXXCRAFT app drives the fabrication and delivery methods at EWDS, replacing manual 2D drawings with a 3D design approach. Now, all of Cunningham’s unique design rules and fabrication know-how is captured in the 3DEXPERIENCE platform for him to use over and over again.

“It speeds it up my design process so much,” Cunningham said. “I create templates or a cut list using BOXXCRAFT and then I’m fabricating. I’m hitting the ground running. It used to take me a day or so to calculate every rise, run, diagonal of each one of these faceted pieces as they go around. Now, I’m saving about 40 percent of my time in production alone and with the certainty that it’s going to come out right and I’m not wasting time trying to calculate in the field.”

Critically, the technology doesn’t replace the creative process. What it does do is speed it up by capturing many of the manual design rules that must be applied to each custom-made product.

“What a craftsperson can’t generally do is scale and produce bespoke products as quickly as they would need to be really competitive,” Kotronis said. “The big difference is seeing that their know-how can be encapsulated into technology and then become actionable to serve them. So, it used to take Eyebrow Window Dormer Supply eight hours to generate a cut list and it’s now done in seconds. All the design rules are prescribed by them. It’s their know-how being put to work.”

EWDS is able to pass on these time savings to the customer by reducing costs and making its product more affordable.

“These windows are very expensive to make,” Cunningham said. “In fact, you could buy three double-hung windows for the price of one of my little round ones. It’s a great advantage that we can reduce the price and make them more accessible to contractors and homeowners. To leverage technology to achieve what you did before quicker, without sacrificing any of the quality and craftsmanship, you’d be foolish not to embrace it.”

As it paves the way for other crafts businesses to widen their scope, EWDS is already reaping the benefits of being able to price its products more competitively in the market.

“What would have taken a fabricator three days to do is now being done in one day,” Kotronis said. “Before, somebody maybe wouldn’t have bought multiple eyebrow window dormers for their house because it was out of budget. But with more efficient production and better understanding of the process, everything is quicker and more cost effective. It’s more favorable in the market. A lot of custom fabricators that would have been priced out of many projects can now compete. The advantage of the technology is that within a standard budget, you can achieve a much higher quality product.”

Guaranteed results every time

The BOXXCRAFT app gives EWDS the ability to show architects and customers exactly what the product would look like on each individual house well before construction commences, helping to abate any concerns early on in the process.

“The architects that we speak with say they would love to put more eyebrow window dormers on houses but they can’t find anyone to consistently build them the way they’re supposed to look – with the sweeps correct – and they wind up being ugly or disproportionate or not roofable,” Cunningham said. “If you look around enough, you see good ones and bad ones and the architects worry about that. They don’t want to get bad ones. We can give good ones to everybody.”

EWDS produces shop drawings and uses the 3DEXPERIENCE platform to create 2D and 3D images that architects can include in their plans, regardless of the CAD software they use.

“Whatever CAD program the architects are working in, we have the ability to digest that information, run it through our app and through the back end with the 3DEXPERIENCE platform and export it back out to them in the format that they’re using so they can place it on their plans and it really sells it to the builder and homeowner,” Cunningham said. “It’s terrific. That’s what BOXXCRAFT does. It powers and enables Eyebrow Window Dormer Supply to deliver certainty to the client.”

Cunningham also is realizing that by carrying out all his design measurements and calculations via the BOXXCRAFT app, he is able to produce an end product that fits even better than before.

“BOXXCRAFT computes every angle, every bevel to two decimal points,” he said. “It’s such a boon to have the certainty that it’s going to get created exactly the way the customer wanted it.”

To leverage technology to achieve what you did before quicker, without sacrificing any of the quality and craftsmanship, you’d be foolish not to embrace it.

Scaling up

EWDS is pressing ahead with plans to expand its business and collaborate with more customers to bring custom dormer products to homes worldwide.

“What really opens the market for them with the cloud is the ability to reach directly to consumers,” Kotronis said. “The vision is to have consumers directly interacting with their design knowledge and having custom products delivered to them.”

Indeed, one of the company’s slogans is “Your design delivered” and today it has the capability for customers to design their own eyebrow window dormer and have it delivered to them in one of three ways: fully assembled, flat packed or full-scale templates.

“You can now go on our website and design any size eyebrow that you’d like,” Cunningham said. “You can adjust the pitch of the roof, the pitch of the eyebrow, the window, width and radius, the length of the eyebrow and you can physically morph the shape of the eyebrow and even put grills in it if you want. In the back end, the 3DEXPERIENCE platform figures out all of the templates for us.”

Being able to offer accurate templates allows EWDS to reach customers it would previously have never been able to service.

“These kits have every piece of plywood, every rafter, every piece for the headers and the full assembly on full-scale templates where you have all the complex geometry figured out for you already,” Cunningham said. “It’s a real time-saver and it bridges the gap of cost-prohibitive shipping.”

The company now can expand its market and deliver high-quality bespoke products to customers in a cost-effective way.

“What was prohibiting Eyebrow Window Dormer Supply’s market? Well they were prefabricating and assembling everything, which has a high-shipping cost,” Kotronis said. “They were already experimenting with flat packs but some of the behind-the-scenes work we did on optimizing their manufacturing allowed them to be more efficient. The biggest eye opener was once we optimized their back of house, we could produce and cut templates using computer numerical control to automatically make these eyebrows. The craftspeople directly cut them, but all the information they need is already sorted for them.”

Transferable applications

Kotronis believes this is just the start for BOXXCRAFT as more companies explore the potential of its design application.

“BOXXCRAFT values craft and creativity,” Kotronis said. “We believe that the people who hold that creativity and craft capability can scale and profit from their abilities in new ways.”

Kotronis and Cunningham are now committed to sharing the virtues of the technology and helping more craft businesses take advantage.

“If we can do this with traditional craft and carpentry, we can do it with about anything,” Kotronis said. “One of the most challenging things for BOXXCRAFT is as a craftsperson, as a designer we would like to believe that everything is unique. We need to get people to see and understand that 80 percent of what they do is repetitive. Yes, it takes creative energy to do it and it takes their knowledge to do it, but that knowledge can actually be put to work for them in new ways. We want to help these talented suppliers compete in an industry which is increasingly moving towards mass customization and production at scale. We would like to be the vehicle that helps them plug and play into that system.”

Focus on BOXXCRAFT

BOXXCRAFT was founded in 2019 by Michael Cunningham and James Kotronis. The company aims to simplify the creation of bespoke products without compromising on quality by helping clients in the construction industry embrace advanced 3D modeling technology to change the way they handle their custom design to fabrication process.

Headquarters: Quogue, New York, US

For more information: https://www.boxxcraft.com