Bold Valuable Technology

Bold takes advantage of the Efficient Multi-Energy Platform industry solution to design and engineer all aspects of its custom high-performance batteries for motorsport, marine and aerospace applications. Thanks to the 3DEXPERIENCE on cloud, the company is able to bring its cutting-edge technology to market faster and manage the full product lifecycle with seamless data flow from concept to production.

Accelerating electrification with high-performance batteries

In a state-of-the-art facility overlooking the Circuit de Barcelona-Catalunya racetrack, some of the electrification and aerospace industry’s best minds have come together to push the boundaries of what’s possible in electric vehicle (EV) innovation. They work for Bold Valuable Technology, specialized in the development of high-performance batteries. Many of them, including Bold’s founders, have honed their skills in the fast-paced world of Formula 1 (F1). Now, this impressive team of engineering talent applies the same rigor, energy and speed to scaling electrification technology for aerospace, motorsport and marine applications as it did pursuing driver’s and constructor’s championships.

“Our mission is to make F1 battery technology available at scale so we can electrify mobility for everyone,” said Gerard Torres, chief operating officer at Bold Valuable Technology. “Our backgrounds in F1 mean that we’re used to working at speed to push the boundaries of innovation, and we want to apply that mindset to electrification – on the road, in the air and at sea.”

Such is the depth of knowledge within the company that everyone from F1 teams to leading aerospace companies seek out Bold’s cutting-edge energy storage solutions, renowned for their high energy density, lightweight properties and superior safety. These customers approach Bold to develop custom high-voltage battery systems and apply its expertise in composites to reduce the mass of battery and inverter enclosures.

“For a particular project, by swapping aluminum for advanced composites materials, we came up with an enclosure design fulfilling the same requirements in terms of safety, emissions testing and so on, yet it was 45% lighter than the original,” Torres said. “All composites material research, selection and validation were solved with the 3DEXPERIENCE platform.”

Since day one, the 3DEXPERIENCE® platform on cloud has been Bold’s technology of choice, which it uses to manage all aspects of its product development.

“Our engineers are used to working in a fast-paced and high-pressure environment and we only want to work with the best solutions in the market,” Torres said. “With the 3DEXPERIENCE platform and applications, it was never a question to look for something else.”

With the 3DEXPERIENCE platform, we will be able to go from an empty CAD screen to industrializing a product.

Rolling start with the 3DEXPERIENCE for Startups

As a young company, Bold needs to make best use of the resources at its disposal and work as quickly and efficiently as possible. That’s why the 3DEXPERIENCE for Startups program made sense for the fledgling business, giving it affordable and immediate access to the full 3DEXPERIENCE solutions suite on the cloud, including CATIA and ENOVIA, as well as online training and support. Bold worked with its trusted technology partner TECHNIA to qualify for the program and get up and running on the platform.

“Being able to tap into the best resources and use the incredibly wide range of applications in 3DEXPERIENCE has been key to our success so far,” Torres said. “The cloud made it really quick to set up and easy to manage, and we can support seamless collaboration across our teams from anywhere in the world.”

From the beginning, Bold has relied on its partnership with TECHNIA to provide the technical support its needs as its business continues to grow and evolve. It’s also allowed the company to focus on what it does best: serving its customers’ engineering challenges.

“TECHNIA has been a true partner at every stage,” Torres said. “They’ve supported us to push boundaries and go against the current to achieve something big. As we grow in headcount, we need new processes and licenses. Sometimes we’ve needed these things to happen overnight and TECHNIA is there to activate things quickly. They help us help our customers.”

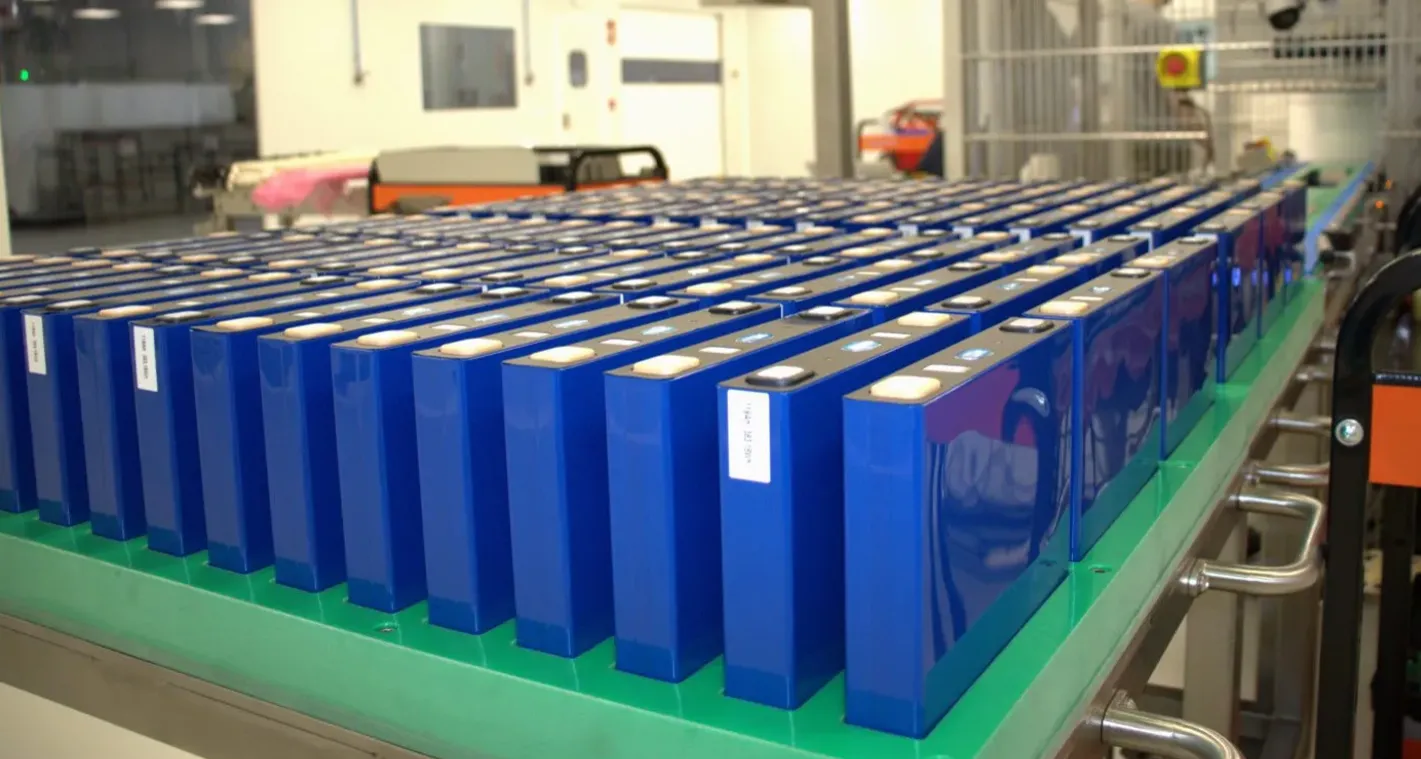

Creating next-gen battery systems for electric aviation

Bold’s latest battery developments combine cutting-edge cell technology and carbon fiber structural assemblies to create lightweight, highly optimized energy storage systems. They also possess industry-leading thermal runaway containment properties, helping to prevent the onset of thermal runaway – where lithium-ion cells overheat and self-destruct – and contain it should an unexpected event occur. This makes Bold’s energy products ideal for high-performance applications and ideally suited to meet stringent aerospace safety requirements.

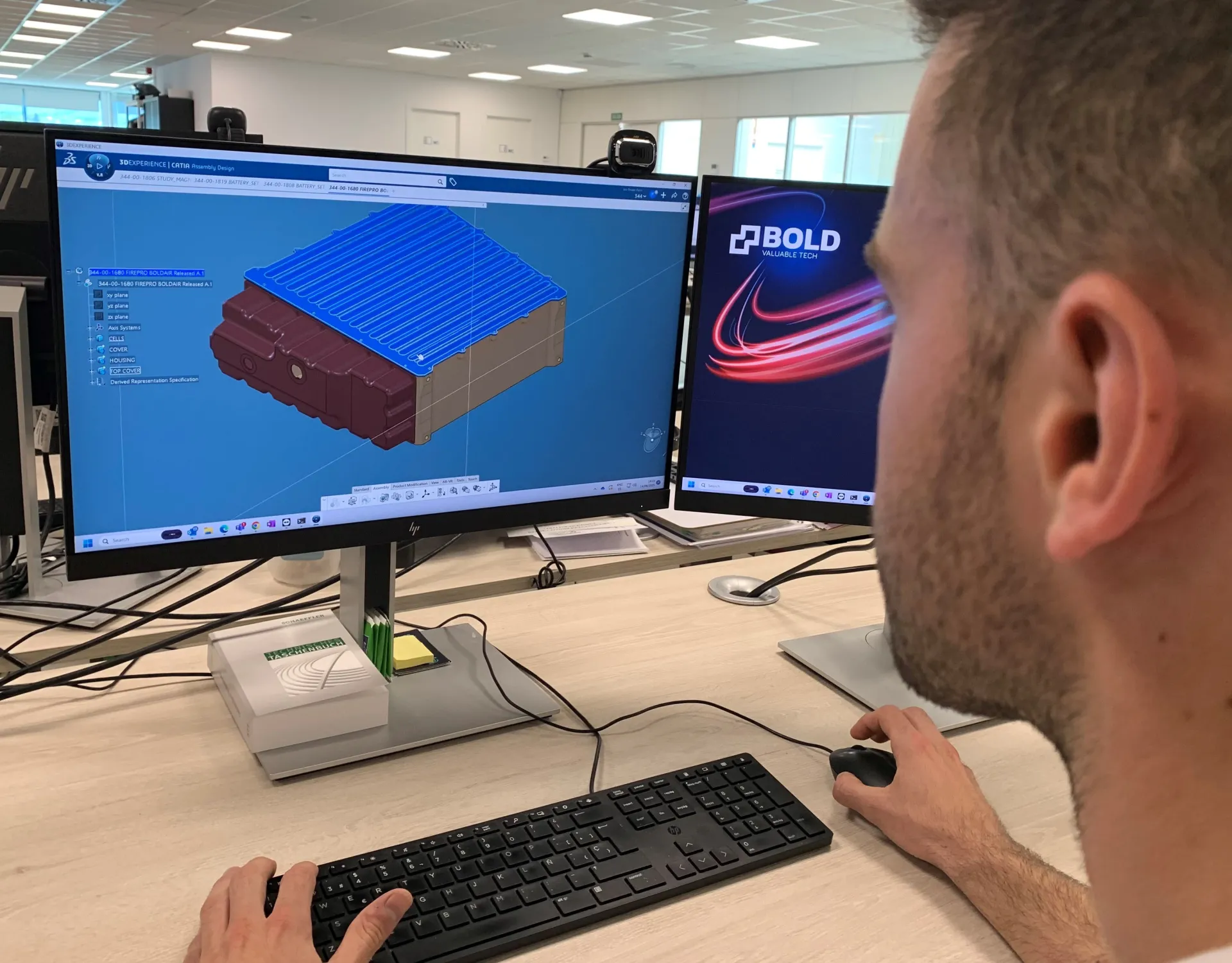

Because of the nature of Bold’s work, no two battery packs are the same. The electrification technology team bases each modular design on a pre-selected cell arrangement and then develops the required mechanical packaging and cooling system for each specific use case. All of this work is carried out in CATIA.

“To achieve these high performance and safety requirements, you need to choose the right materials,” said Jon Ander Ferri, senior design engineer at Bold Valuable Technology. “That’s largely down to our knowledge and experience, but CATIA has many functionalities that enhance our work. When we’re producing a plastic injection component, for example, it allows us to check where there is material accumulation and identify where improvements can be made.”

Engineers also benefit from the ability to share their work within the 3DEXPERIENCE platform. It allows them to work concurrently in teams on the same product and easily keep track of modifications.

“When developing the battery enclosure, we make use of the Part Design module in CATIA to create very precise mechanical components,” Ferri said. “We save each one in the platform, so that everyone in the team can access the component and see it in the context of the wider assembly. If we need to make any changes, we can easily access individual components, and any low-level changes are automatically reflected upstream. We can also release the bill of materials directly from the design, removing the risk of human error.”

These efficiencies not only speed up development time, but also help to bring down costs while keeping track of design changes – a critical factor when developing new battery systems for the less mature electric aviation market.

“We have to go through different development stages very fast and maintain traceability for every single component that we’re developing and ultimately launching into production,” Torres said. “With the 3DEXPERIENCE platform, we can push the boundaries of what’s achievable and deliver the best technology to our customers."

One innovation environment as a backbone

Equipped with its own onsite manufacturing and testing plant, Bold is committed to shortening lead times while maintaining full control of the end-to-end development process to guarantee the quality it has built its reputation on. In the same way, ENOVIA on the 3DEXPERIENCE platform serves as the backbone for its product lifecycle management (PLM). Its robust data management capabilities ensure a seamless digital thread from one development stage to the next without losing information along the way.

“We must handle structural, electrical and thermal challenges, all packaged in a very small space with lots of power,” said Pau Martinez, lead battery mechanical design engineer at Bold Valuable Technology. “Multiple disciplines must come together, and they all need to be understood and integrated. The 3DEXPERIENCE platform has all the applications we need in one place and, because it’s cloud- based, we can collaborate from wherever we are in the world. Everyone is looking at the same data.”

“One of the great things about the platform is how it enables us to manage the whole product lifecycle, which is critical when we’re starting on new products from scratch,” Ferri added. “Within one place we can manage the release process, define templates and determine how many steps and people we require in each process.”

Using the 3DEXPERIENCE platform, the team is currently developing BoldAir, a market-leading 285 watt-hour per kilogram high-voltage battery system specifically designed for advanced air mobility applications. In a very short time frame, Bold has gone from a clean sheet of requirements to the design verification plan and report phase, with production expected to commence within months.

“We have had to release and manage thousands of files for every component,” Torres said. “With the 3DEXPERIENCE platform we can go from an empty CAD screen to industrializing a product.”

Positioned for fast growing

As Bold grows its headcount and takes on bigger, more complex projects, it knows it can rely on the 3DEXPERIENCE platform to help attract new talent and keep its business connected even as it expands beyond its premises in Barcelona.

“It’s a strategic solution for the business on many levels,” Torres said. “The fact you can tell a prospective candidate that you’re using 3DEXPERIENCE and CATIA really helps. Having recently set up a footprint in the UK and looking to expand into the US, the only way we can make everyone work in a seamless, cohesive way is by using the platform.”

Backed by the 3DEXPERIENCE platform, Bold continues to deliver on its vision to make F1 electrification technology available at scale and build on its reputation to become a leader in energy storage solutions for the most demanding applications.

“All businesses exist to serve a purpose, to solve problems for their customers,” Torres said. “We exist to supply the best battery systems so our customers can electrify their fleets and vehicles. It has been critical for us to demonstrate to them that we have the best tools required to develop this cutting-edge technology. From the start, we knew that the 3DEXPERIENCE platform was the right solution for us.”

Discover more about the Efficient Multi-Energy Platform industry solution experience.

Focus on Bold Valuable Technology

Bold Valuable Technology designs, tests, manufactures and delivers high-performance, finished battery systems and lightweight structure solutions. The company was founded in 2019 with one objective: to make Formula 1 battery technology available at scale. Bold’s experience in energy storage solutions and carbon fiber materials uniquely positions it to accelerate the speed of electrification in aerospace.

For more information: https://boldvaluable.tech

Focus on TECHNIA

TECHNIA paves the way for innovation, creativity and profitability. The global PLM company is committed to making technology and innovation work in a practical world. This is demonstrated by the resources that it applies to developing exceptional capability in the latest software and process developments. TECHNIA learns before its customers have to, seeking out and identifying the advantages that new products and processes can offer, often within its own business before applying it to its customers.