Airbus

Airbus has deployed Dassault Systèmes’ (3DS) applications to drive a global collaborative solution throughout the value chain from engineering to manufacturing..

A technological prowess

As part of its “Future by Airbus” program, Airbus asked 20,000 people at airshows, events and online what they expect from air travel in 2050. The answers were not surprising: cheaper, greener, more sustainable, less stressful, quieter and more fun. In the past, it was enough to get passengers to where they wanted to go safely and on time. While this is still true today, airlines are now focusing on the passengers’ flight experience. With the A350 XWB (Xtra-Wide Body) – the newest member of the Airbus family of long-range jetliners – the airline manufacturer bets the passenger flight experience will be a positive one. With already 750 planes in the Airbus order books, customers apparently agree.

The A350 XWB is designed with the customer experience in mind, from cabin ergonomics to the in-flight entertainment. The A350 XWB combines the latest advances in aerodynamic wing design with an intelligent airframe. Both the fuselage and wing structures are made of carbon-fiber – more than 50% of the entire jet. “The A350 XWB is the first plane to so extensively use this light-weight material, which greatly contributes to its fuel efficiency,” said Didier Evrard, executive vice president, head of A350 XWB program at Airbus. “Its advanced wing design makes the A350 XWB a quieter and more aerodynamically efficient aircraft. Flying will be a whole new experience.”

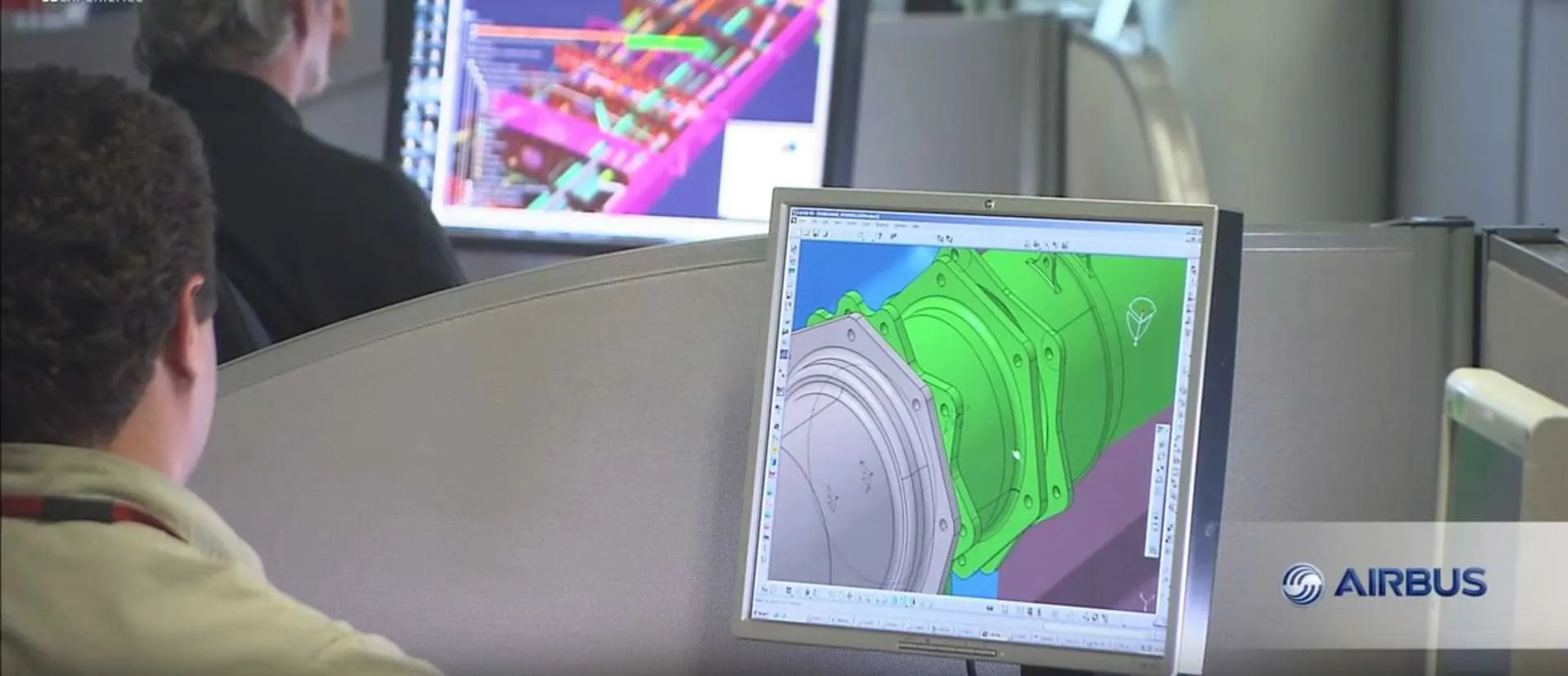

To achieve this goal, Airbus has deployed Dassault Systèmes’ (3DS) applications to drive a global collaborative solution throughout the value chain from engineering to manufacturing, integrating new improvements over previous programs.

Collaborative Innovation

Reaching an unprecedented level, collaboration is at the forefront of Airbus’ innovation strategy. “When we started the program,” Evrard said, “we really needed to develop methods and tools which were radically different from the A380, not only to ensure that all engineers involved in development worked on the same design platform but also to have them communicate in a single environment.” On the A350 XWB program, up to 4,000 people were connected daily to the platform, with 85% of them coming from the supply chain.

“For previous programs, each site had its own Digital Mock-Up (DMU) and everyone worked separately,” said Antoine Scotto, head of the Product Lifecycle Management (PLM) program for the A350 XWB at Airbus from 2007 to 2011. The lack of communication extended design time and introduced errors that drove up costs. “This time, we federated our development platforms under one umbrella ENOVIA and provided Airbus employees and the extended enterprise with access to this unique data reference. With ENOVIA, synchronization takes only a few minutes, against several days previously,” he added.

By reengineering its development processes, Airbus has facilitated collaboration at the design and development phase all the way to production. “Dassault Systèmes' solutions have helped unleash a collective exchange of ideas among program stakeholders, which contributed to improving everyone’s efficiency,” Scotto said.

We introduced harmony in our processes, methods and tools, saving precious time that we instead spent on innovation.

Simplifying processes, improving quality

“We had many challenges including a very aggressive development schedule and the need to ramp-up production quickly to satisfy our delivery commitments,” Evrard said. “With Dassault Systèmes' applications, our design quality and efficiency have considerably improved.” “We used CATIA to design the aircraft’s structure, the installation systems, the tubing, the composites parts, and the electrical systems completely in 3D,” Scotto explained.

For example, Airbus reinvented the way they sized and installed the hydraulic and electrical systems. “With CATIA, we implemented a full 3D Master approach to design the electrical harness installation for the A350 XWB, which simplifies the process and improves overall design quality,” Scotto said. Harmonizing the end-to-end harness installation process reduced costs and lead time, and supported the A350 XWB industrial ramp-up. “Engineers have reduced the time needed to update an installation plan by 50%, and decreased the design change requests generated when creating manual 2D drawings by 25%. Everything was installed, fitted and verified digitally and if there were any errors, they were corrected before physical installation,” he added.

Dramatic increase in efficiency

The DMU enabled Airbus to link manufacturing with the design office. “Any changes made by the design office were communicated to manufacturing in real-time. This dramatically reduced tooling production time,” Scotto said. “The quality of the design was so outstanding that manufacturing almost never requested any redesign work,” Evrard added.

Engineers performed realistic nonlinear analyses with SIMULIA to predict, very early in the design process, the strength and behavior of the aircraft’s structure. “We created very large simulation models based on the CATIA design information and performed full-scale, nonlinear structural simulations,” Scotto said. “With SIMULIA, we transitioned from an approximate, linear analysis approach to a more accurate, nonlinear analysis, which gives us a deeper understanding of how the structure really performs in a given situation.”

From manufacturing engineering to plant operations, DELMIA was used to secure program lead time and ensure aircraft manufacturability. In addition, DELMIA enhanced our ability to design and optimize industrialization from the assembly station to elementary assembly operations and support automation. For the Airbus A330, the final assembly line cycle took around four months. By starting the cabin installation very early, the A350 XWB assembly process was shortened by 30%.

3DS Industry Services support was instrumental in implementing and deploying the complete A350 XWB environment. “The collaboration between Airbus’ and Dassault Systèmes’ teams was very strong,” Evrard said.

Digital continuity for customer services

The benefits of using a single DMU for the A350 XWB do not stop with engineering and manufacturing but extend to downstream processes used in customer services. While in past programs customer services relied on manually drawn 2D illustrations, digital continuity provided by Dassault Systèmes' applications enabled Airbus to implement customer service processes that directly reuse the DMU.

For example, using 3DVIA, Airbus implemented a Structural Repair and Maintenance (SRM) system enabling access, query and navigation within the DMU, to identify structural parts for allowable damage or repair. The benefits of using 3DVIA include a much easier identification of the parts, as well as the removal of the manual work required to create the 2D illustrations and call-outs.

First flight and beyond

Dassault Systèmes' applications have become the core and strategic enabler for Airbus on the A350 XWB program. The real moment of truth was the A350 XWB’s maiden flight on June 14, 2013. “All expectations converged on this date,” Evrard said. “Of all the challenges we faced along the way, this was the one everyone anticipated from the very first design sketch. This first flight was a success.” The A350 XWB team’s newest challenge is to accelerate production ramp-up, in collaboration with their supply chain, to meet Airbus’ delivery commitments. “With all the right people accessing a common DMU, communication is easy, decisions are made on the fly, and problems are solved faster,” Scotto affirmed.

“Making the A350 XWB possible presented tremendous technical, technological and organizational challenges due to the complexity of the program and the number of outsourced stakeholders,” Evrard said. “But with Dassault Systèmes’ solutions, we introduced harmony in our processes, methods, and tools, and saved precious time that we spent, instead, on innovation. For my final program as director, I could not have hoped for a more thrilling challenge.”

Discover additional insights from a CATIA user.

Airbus

Headquartered in Toulouse, Airbus is owned by Airbus Group, a global leader in aerospace, defense, and related services. Airbus is the world’s leading aircraft manufacturer whose customer focus, commercial know-how, technological leadership, and manufacturing efficiency have propelled it to the forefront of the industry. Airbus’ modern and comprehensive product line comprises highly successful families of aircraft ranging from 107 to 525 seats.