Marine Suppliers

Empower marine suppliers with advanced digital solutions to innovate, collaborate and deliver high-quality systems, equipment and components for the shipbuilding industry.

Transforming the Marine Suppliers’ Business With Innovation

Transforming the marine suppliers’ business with innovation means embracing digital technologies to streamline operations, enhance collaboration and accelerate delivery. By integrating advanced design, simulation and manufacturing solutions, marine suppliers can optimize processes, reduce lead times and ensure product quality.

Digital transformation enables seamless communication with shipyards and partners, supports rapid adaptation to changing requirements and fosters continuous improvements. This approach empowers marine suppliers to deliver reliable, high-performance systems and components that meet the evolving needs of the shipbuilding industry.

Key Challenges for Marine Suppliers

- Complex Supply Chain

- Quality and Compliance

- Collaboration and Integration

- Sustainability and Efficiency

Managing Complex Supply Chains

Marine suppliers operate within global supply chains that require precise coordination among manufacturers, logistics providers and shipyards. Delays, disruptions or miscommunications can impact project timelines and budgets.

Advanced digital solutions enable real-time tracking, improve forecasting and support seamless collaboration between all stakeholders. Increasing visibility and control over inventory, shipments and production schedules will allow marine suppliers to minimize risks, respond quickly to changes and ensure on-time delivery. These advantages ultimately improve their reliability and reputation in the competitive shipbuilding industry.

Ensuring Product Quality and Compliance

Marine suppliers must deliver systems, equipment and components that meet rigorous quality and regulatory standards. Products must perform reliably in harsh maritime environments and comply with evolving international regulations.

Hence, marine suppliers must work on a digital platform to facilitate robust quality management by integrating testing, certification and documentation processes. Automated traceability and real-time monitoring will help them identify and resolve issues early, reducing costly rework and recalls. By prioritizing quality and compliance, marine suppliers build trust with shipbuilders and contribute to safer, more efficient vessels.

Driving Competitiveness Through Collaboration and Integration

Marine suppliers must collaborate closely with shipyards and ship owners to address changing specifications, customization requests and technological advances.True competitiveness now depends on developing tailored solutions through integrated workflows and open communication.

Digital transformation empowers suppliers and clients to work together in flexible design environments using collaborative tools and rapid prototyping to manage complex requirements and accelerate iteration cycles. By fostering seamless integration and teamwork, marine suppliers can swiftly adapt to evolving needs, deliver differentiated, value-added solutions and maintain a strong position in an innovation-driven market.

Driving Sustainability and Efficiency

Suppliers face increasing pressure to reduce environmental impact, optimize resource use and minimize waste while maintaining profitability. As such, digital tools are critical to support lifecycle assessment, eco-friendly material selection and energy-efficient manufacturing processes.

By embedding sustainability — including alternative fuel solutions — into every stage of production, marine suppliers not only comply with regulations but also enhance their market appeal and competitiveness. Embracing sustainable practices positions suppliers as responsible partners in the transition to greener shipbuilding.

Integrate Sustainability in Marine Suppliers’ Business

Sustainability is becoming a strategic priority for marine suppliers as the maritime industry pursues greener operations and stricter environmental standards. By leveraging digital solutions, suppliers can assess the environmental impact of their products, optimize material usage and minimize waste throughout the manufacturing process.

Sustainable practices support regulatory compliance and enhance marine suppliers’ reputation and competitiveness. They can contribute to a more sustainable future for the shipbuilding industry by embracing eco-friendly materials, energy-efficient manufacturing and lifecycle assessment.

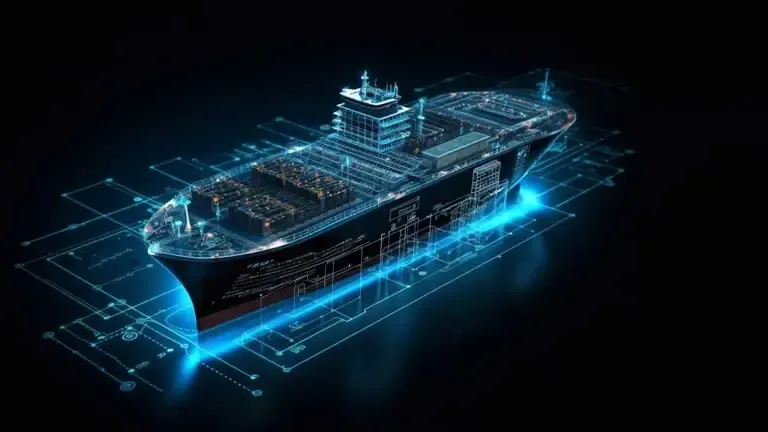

How To Transform Your Business

Key Benefits of Dassault Systèmes’ Marine Suppliers Solutions

Dassault Systèmes’ integrated solutions provide marine suppliers with a competitive advantage:

Enhanced collaboration and integration

Streamline communication and coordination with shipyards and partners through a unified digital platform for real-time collaboration.

Improved product quality and compliance

Ensure high-quality, compliant products with advanced 3D design, simulation and comprehensive lifecycle management tools.

Increased agility and innovation

Rapidly adapt to customer needs and market changes with flexible design, digital prototyping and modular innovation tools.

Our Success Stories of Marine Suppliers

Digital Solutions for Marine Suppliers

Our Solutions for Marine Suppliers

Marine suppliers can tackle key industry challenges with Dassault Systèmes’ dedicated Marine & Offshore industry solution experiences, powered by the 3DEXPERIENCE® platform.