Industrial Engineering: Manufacturing Planning

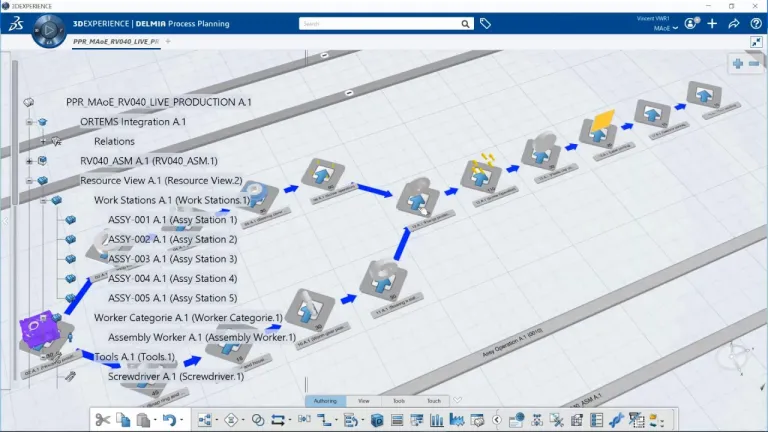

Enrich the product and resource definition; define and validate a process plan and create work instructions or the manufacturing process to meet production goals.

Digital visualization of resource and process changes help accelerate time-to-production in any scenario, from any location, leveraging the cloud.

Manufacturing Planning in action

- Train Virtually

- Create 3D Work Instructions

- Enrich Product and Resource Definition

- Define Process Plan

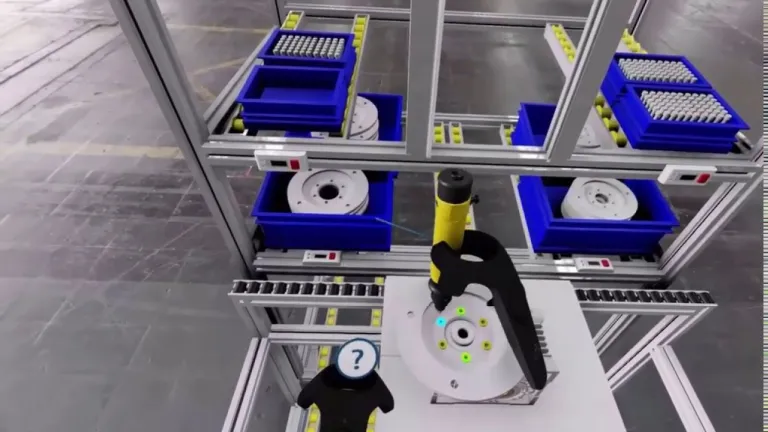

Train Virtually

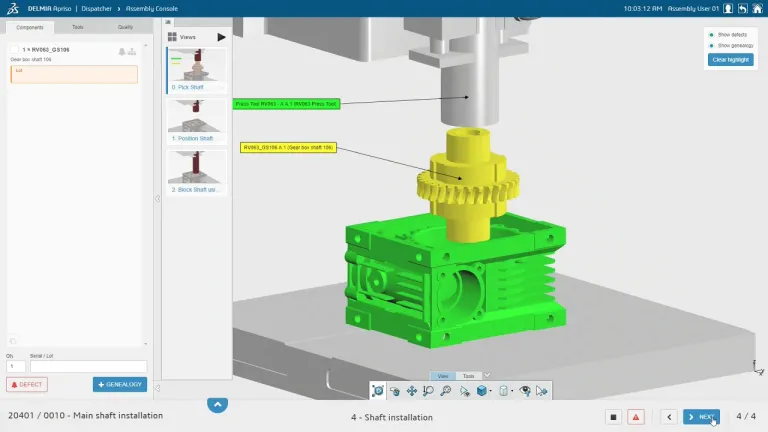

Create 3D Work Instructions

Finally, it is time to create the work instructions whether it is for the machine or the operator.

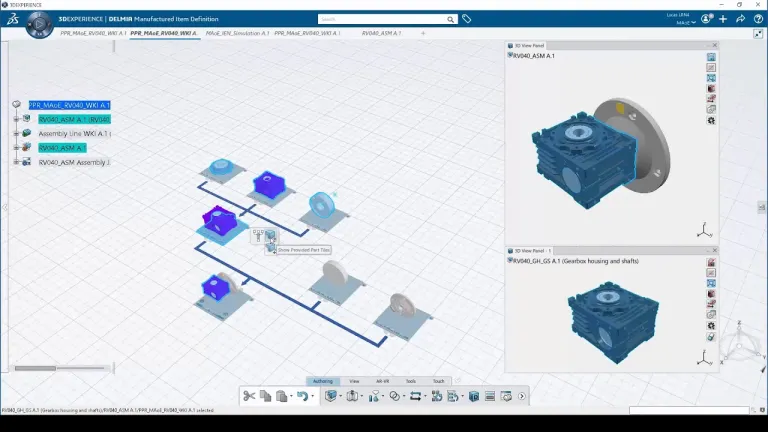

Enrich Product and Resource Definition

Define Process Plan

With the definition, it is time to design the process plan which will include the actual sequence of events.

Resources

Contact our sales team

Are you ready to take the next step in your Factory of the Future journey? We can help! Fill in the form to have a Dassault Systèmes Manufacturing expert contact you. Include questions and topics you would like to discuss to tailor the call to your needs.

Next: 03 Planning & Optimization

Supply Chain Planning & Optimization across all planning horizons; gain visibility with planning and scheduling through the ability to model, simulate and optimize alternative supply and production plans to minimize disruptions.