Spark Racing Technology

Spark Racing Technology needed to design, assemble and deliver an electric-powered racing car on time and within budget to all teams participating in the fourth season of the Formula E racing series.

Reinventing the electric car with a new championship

Sustainable mobility solutions have become a key concern in today’s world and of particular focus for an automobile industry seeking to reinvent itself by adopting cleaner technologies. Worldwide motor shows reflect this change. Most car manufacturers have redesigned their engines for more energy-efficiency, offering electric-powered alternatives for environmentally conscious drivers.

The world of automotive racing is no exception. In 2012, the Fédération Internationale de l’Automobile (FIA) commissioned France-based Spark Racing Technology (SRT) to design and build the first generation 100% electric-powered vehicles for the all-new Formula E car racing competition. In partnership with Renault for the components integration, Dallara for chassis work, McLaren Electronic Systems for the powertrain, Hewland for the gearbox, and Williams Advanced Engineering for the battery, SRT supervised the project, producing and assembling 90% of the cars and delivering the remaining 10% for extensive testing.

In the years since, SRT has continued to be the main FIA partner with its Spark-Renault SRT_01E model becoming the base car for the manufacturer teams. The car has proven almost faultless throughout the seasons, requiring only a slight modification to the suspension.

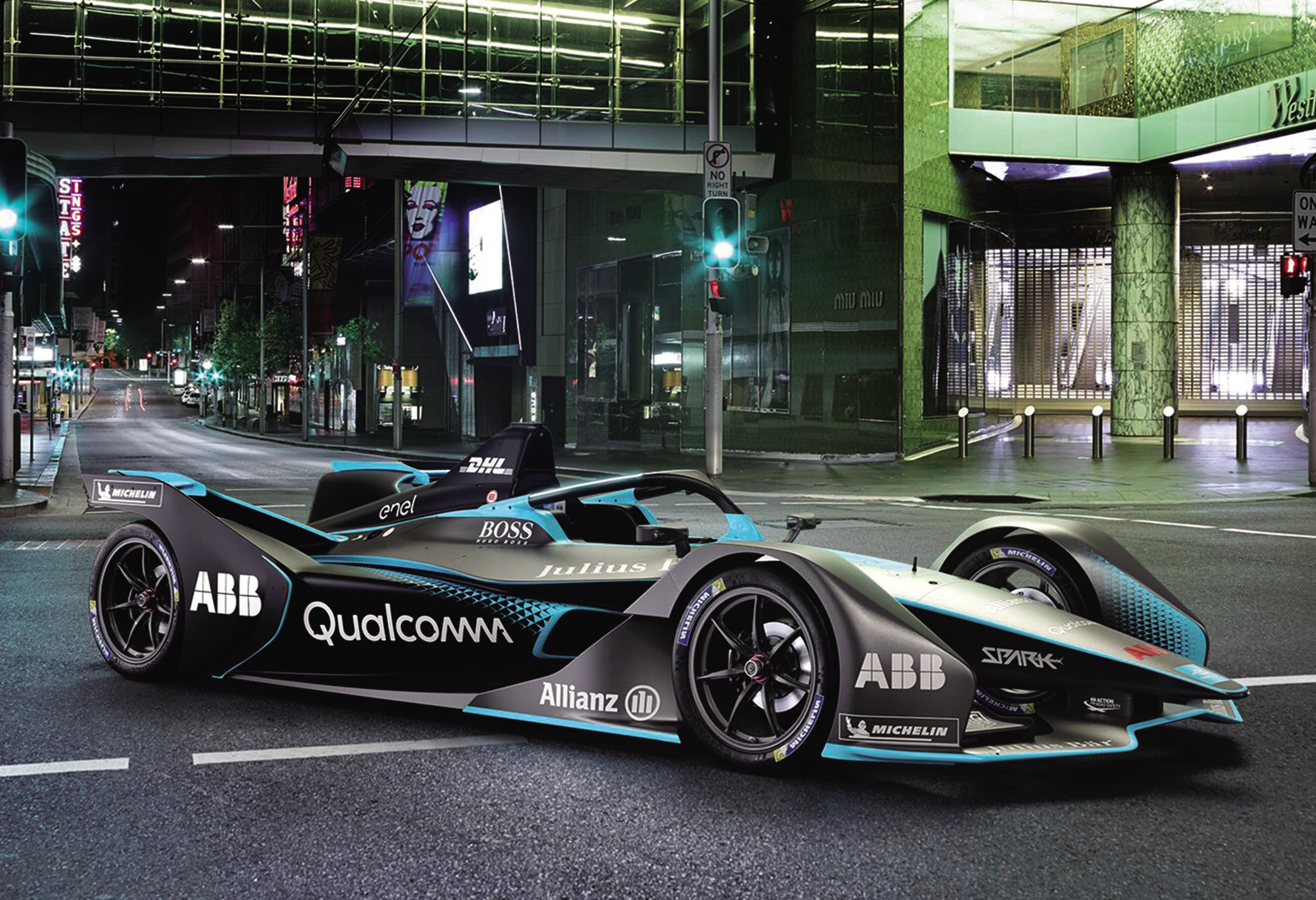

When the FIA launched a call for tenders for its new Formula E car slated to race in 2018 and 2019, SRT bid again and won. The Spark SRT05e, also known as the Spark Generation 2 — or Gen2 — was born.

“Today, Spark is the only racing e-car manufacturer,” said Théophile Gouzin, CEO of Spark Racing Technology. “With its unique knowhow in the integration of electric powertrains into a racing car, Spark is, and will remain, a leader in electric drive in the world of competition.”

By using the 3DEXPERIENCE platform, we have a reliable and high-performing solution […]. It has opened many doors for us in terms of new business.

Next generation vehicle

SRT designed and assembled a new cockpit, chassis, brakes, wheels, suspension and body using many of its own components for the Gen2. The battery was designed by McLaren Applied Technologies and installed in the car by SRT. Each team uses the same baseline vehicle but can then customize it by designing and installing its own powertrain, engine, controller, electronic systems, onboard software and gearbox.

“The car we developed will be used by the 40 teams competing in the race,” Gouzin said. “Each team is sponsored by a car manufacturer, who have come to appreciate our craftsmanship and creativity. Some even rely on our engineering skills to design concept cars for them as well.”

SRT used Dassault Systèmes’ 3DEXPERIENCE® platform to digitally design and assemble the Gen2’s components before physical build. In less than two years, the team delivered the car on time thanks to its expertise, the robustness of the platform and the collaboration model it enables. “To make this project a success, we needed tools enabling us to go as fast as our ambitions, and that’s what we found through 3DEXPERIENCE,” Gouzin said. “Choosing the 3DEXPERIENCE platform was a clear win. For example, it enables us to assemble an entire car, produce accurate surfaces and manage our data efficiently.”

Dassault Systèmes business partner, Keonys, a Cenit company, introduced SRT to the 3DEXPERIENCE platform and was responsible for implementation, training and transferring the company’s legacy CATIA data to the platform. Installation was out of the box with only minor tailoring to configure the system to SRT’s workflows. “We had severe time constraints to design and build the Gen2 and Keonys’ responsiveness and express training helped bring our engineers quickly up to speed to meet our deadline,” Gouzin said.

“The daily challenge when I create a new part is to make sure its function, specifications and price comply with customers’ requirements,” said Mélanie Péquet, mechanical engineer at Spark Racing Technology. “In this context, 3DEXPERIENCE helps us create parts to meet customer needs. It’s a powerful design tool meeting Spark’s needs. The platform saves us time; it is simple and very intuitive to use.”

“We are a small team,” Péquet added. “We must be agile, responsive and the collaboration must be efficient. For example, if my colleague worked on a specific part and is on our customer’s site for tests, I can take the lead on the 3D model and modify it from the office, test it in a virtual environment, release it, and send it directly to the customer. Traceability enables us to save time.”

It’s a powerful design tool meeting Spark’s needs. The platform saves us time; it is simple and very intuitive to use.

Creating new business opportunities

Delivering a car on time was a must to gain each team’s trust. “As unique provider of the 40 electric vehicles to the competing teams, any delay means the competition cannot take place, which would be an embarrassment for the FIA and, of course, for Spark,” Gouzin said.

Delivering a car free of defects was a serious challenge for SRT. “In the past, the teams that raced with our cars were small, private and relatively unknown entities,” Gouzin said. “Little by little, these small teams partnered with big car manufacturers that participate in this competition to demonstrate their knowhow in terms of electric-powered cars. If one of our parts is defective, they lose the race because of us. So quality and precision are mandatory. By using the 3DEXPERIENCE platform, we have a reliable and high-performing solution that also is used by many of these automotive manufacturers, some of which we’ve come to work with on other occasions over the years. Many of them require CATIA-native models when we send them our designs, which has opened many doors for us in terms of new business.”

Another challenge for SRT was the battery. “Each race lasts 45 minutes, but the battery we used four years ago didn’t,” he said. “It discharged before the end of the competition. As a result, each pilot had to use two cars to complete the race, changing cars midway through the competition. Since the first version of our car, huge progress has been made to the components and to the weight of the vehicle. Making it lighter has enabled us to install more batteries that double the car’s autonomy. To find the best configuration and layout, we used the 3DEXPERIENCE platform design application CATIA to rapidly test alternative designs in a digital environment before choosing the best one for physical assembly.”

New horizons on the e-vehicle market

Outside the world of electric car racing, SRT’s goal is to expand its business by providing its electrical vehicle knowhow to other sectors. “We are currently working on an electric motorcycle for urban mobility needs,” Gouzin said. “We partnered with a US-based motorcycle manufacturer and created Vanguardspark with the objective, in five years, to sell 3,000 motorcycles per year.”

SRT, however, does not intend to abandon the Formula E circuit anytime soon. “Most big car manufacturers today have acquired knowhow and expertise in electric car design they didn’t have in 2012 when electric single seat vehicles were an innovation,” Gouzin said. “But it’s difficult for them to deliver these types of cars at an affordable price. Even for us, it’s a challenge. Our cars are expensive [350,000 Euros/Formula E car], but we use our technology and expertise in ultra-high performing cars to propose innovative solutions.”

For instance, carbon is not commonly used in cars mass production because it’s too expensive. SRT could provide automakers a more affordable carbon chassis that facilitates technology transfers with their standard models. “For example, we recently filed a patent on a carbon structure that can be used to house a battery, giving us a 10- to 20-year head start on major car manufacturers that are not currently envisioning this solution because it can’t easily be transposed to mass-produced cars,” Gouzin said.

Gouzin reflects on the benefits electric car racing can have for the everyday driver. “If we compare the evolution of the electric racing car with the improvements made to Formula 1 (F1) cars in the past five years, there were fewer technological advances in F1 than in the electric car sector,” he said. “But that’s also the objective of a race like Formula E: to develop technologies that can benefit the cars we drive on the road every day.”

Focus on Spark Racing Technology

Engineering company specializing in the design and build of hybrid and electric powertrains and official supplier of a fully electric racing car at the FIA Formula E Championship

Products: the Spark-Renault SRT_01E and the Spark SRT05E (Gen2) fully electric single-seaters

Employees: 12

Headquarters: Tigery, France

For more information: www.sparkracingtechnology.com

Focus on Keonys, a Cenit company

Keonys is a key value-added reseller from Dassault Systèmes and deploys the entire software portfolio for its clients: the 3DEXPERIENCE® platform and its applications – CATIA, DELMIA, ENOVIA, SIMULIA and 3DVIA. Keonys is a major provider of support and consultancy services for companies involved in digital transformation in line with the objectives of France’s Industry of the Future plan.

For more information: www.keonys.com