Märklin

Innovating and growing with Dassault Systèmes PLM solutions.

We are proactively strengthening product development because Märklin is by far the most innovative company in the industry and because this lays the foundation for the company’s continuing success.

LEADING TOY TRAIN INVENTOR

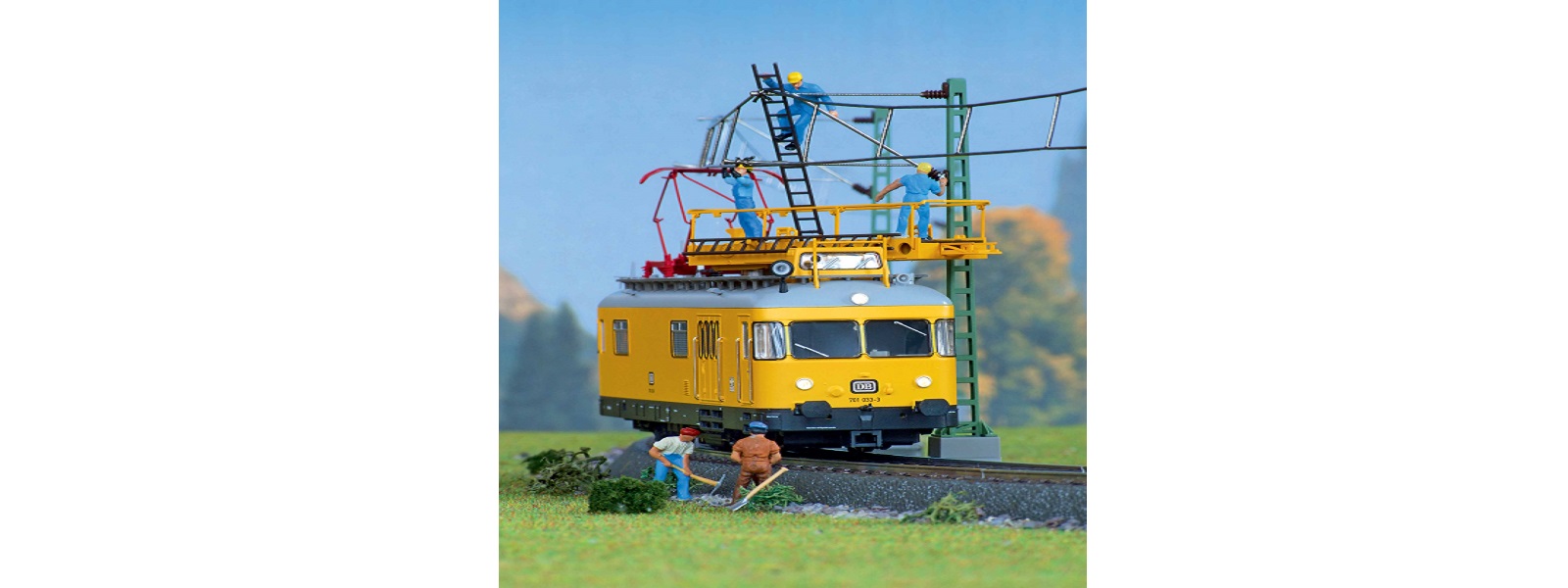

Märklin, world leader in model railroading, was founded in 1859, producing at the time, doll’s house accessories of lacquered tinplate. The company is known for its trueto-life models and the quality of its products, which have won the Göppingen manufacturer its cult status with toy train aficionados all over the world. In collectors’ circles, wagons and models regularly fetch record prices.

Product development is at the very heart of the company whose engineers develop between 350 and 500 new articles a year in the model-trains line alone. Its fine-detail work is one reason for the outstanding quality of its products. “We are proactively strengthening product development because Märklin is by far the most innovative company in the industry and because this lays the foundation for the company’s continuing success,” explained Dr Kurt Seitzinger, CEO of Gebr. Märklin & Cie GmbH.

TRANSFORMING A FRAGMENTED ENVIRONMENT INTO AN INTEGRATED SYSTEM

One of Märklin’s concerns was its heterogeneous system, which impeded data flow between the sites and the developers. So the management team decided to reorganize its development infrastructure and processes. Michael Zauner, project manager at Märklin, explained the conditions at the outset: “The development team’s technical environment had become fragmented and internally incompatible as a result of the acquisition of companies like Trix and LGB – with some work still occasionally being done manually on the drawing board.”

“The sheer speed at which innovation is taking place at Märklin means that an integrated process chain is an absolute necessity,” stated Michael Zauner. So, Märklin launched a PLM program whose objective is to enable developers to work better together in a homogeneous data environment and with no restrictions on data exchange. “We expect a reduction of 30% in construction lead times and costs,” said Zauner.

A foundation for product development CATIA and ENOVIA SmarTeam from Dassault Systèmes (DS) were chosen to manage the design work and all associated data for this process. “The DS solutions fulfill the core criterion of optimally combining single-source CAD and PLM to ensure integrated information flow,” explained Zauner. This integrated foundation meant that conversion along the way from product development to production became obsolete.

IMPROVEMENTS IN DATA MANAGEMENT AND METHODOLOGY

The project pilot led to some interesting conclusions. First the CATIA and ENOVIA combination manages previous data initially handled by four CAD programs thereby considerably simplifying IT administration and costs. Märklin also shelved the document management solution currently in use because it had become redundant. A topdown design methodology has also been firmly established throughout the group by means of handbooks.

In addition, ENOVIA’s document and product data management homogenize the data environment, and CATIA design data can be directly used for NC programming. Relief is also provided thanks to the automatic generation of parts lists and uniform management of all data, irregardless of format (photographs, office documents or 3D models incorporating process data).

OPTIMIZED PRODUCT DOCUMENTATION CREATION AND TECHNICAL COMMUNICATION

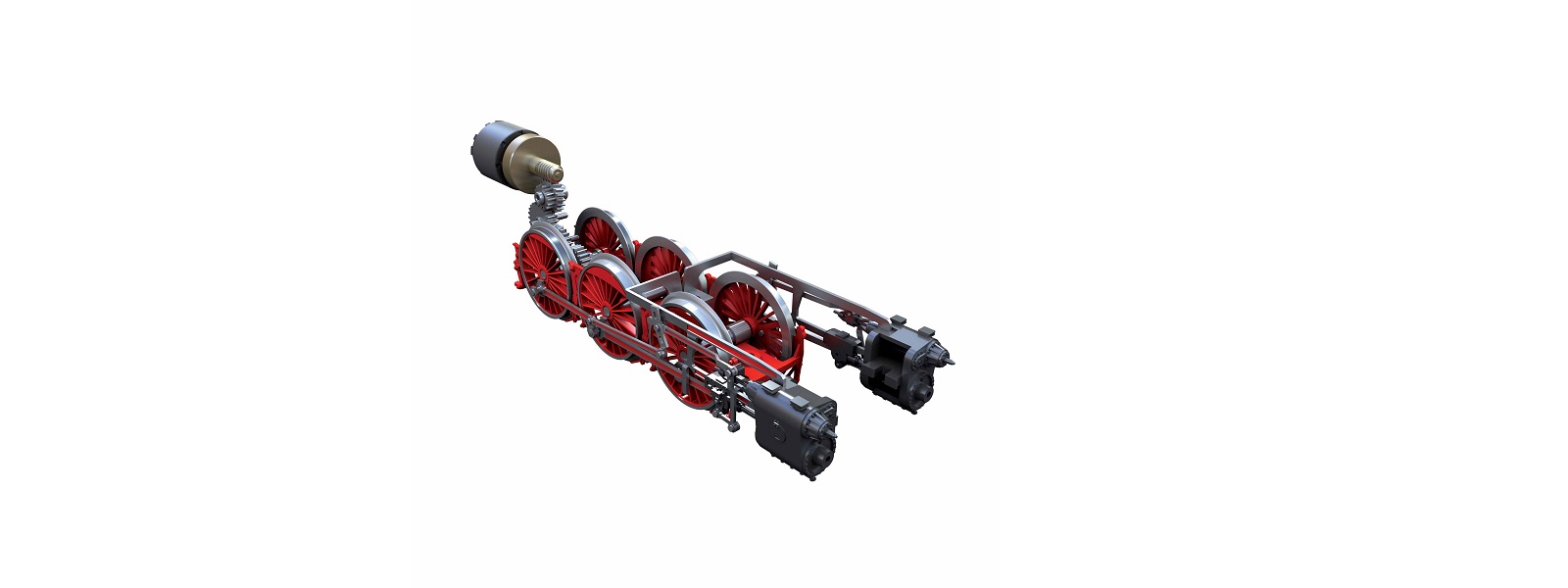

To fully complement the uniform 3D approach, the project pilot also implemented 3DVIA Composer to improve the product documentation process. Technical illustrations such as exploded views are now easily produced in-house by non-engineering personnel, saving outsourcing costs and enabling the work to be completed more often in parallel with the design.

Thanks to the ability of 3DVIA Composer to leverage CATIA data, anyone that needs to communicate about the products using 3D experiences or traditional technical illustrations can obtain the 3DVIA Composer data directly from ENOVIA. Information flow between departments is increased and data is kept up to date by the system. “ENOVIA SmarTeam 3D-viewing functionality is helping nearly 320 employees of all experience levels to more effectively communicate using 3D as a universal language,” Zauner stated.

The DS solutions fulfill the core criterion of optimally combining single-source CAD and PLM to ensure integrated information flow.