Push forward practices

Sustainability implies a transformation of business and professional practices.

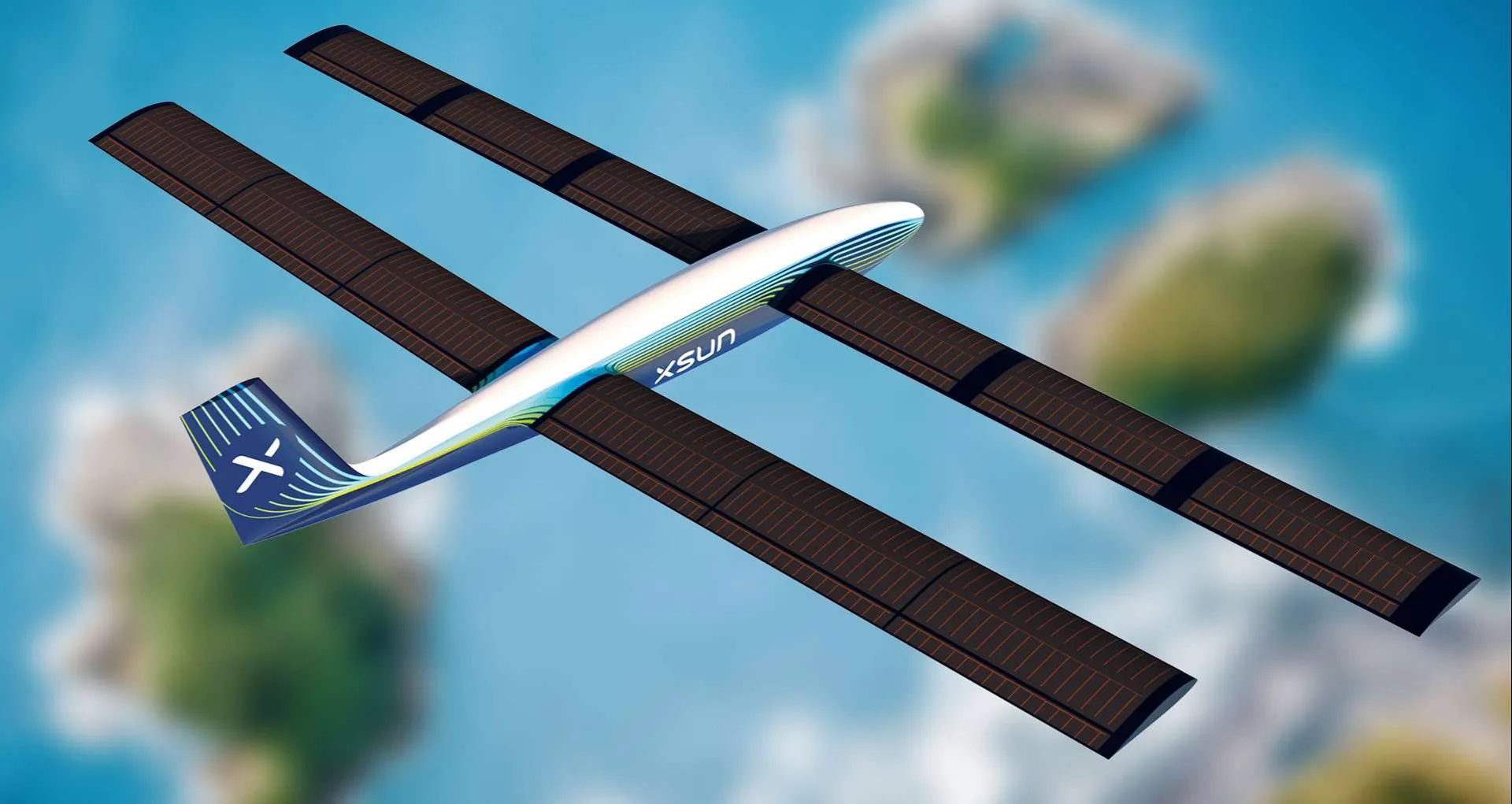

French startup XSun is designing and developing an energy-independent solar drone system that can make its own decisions. Its first product is revolutionary: a drone with double wings that are not stacked, as in a biplane, but arranged side by side to increase the surface area for photovoltaic cells and ensure optimal flight performance. Boosted by support from the 3DEXPERIENCE Lab, XSun adopted the 3DEXPERIENCE platform on the cloud, allowing its teams to collaborate effectively when designing, simulating and testing the drone. This flying machine has potential applications in numerous areas; land and sea observation, protection of fauna and flora, monitoring of atmospheric pollutants, defense and security applications as part of border and maritime surveillance, and checks on linear infrastructure, including roads and oil and gas pipelines.

XSun’s main challenge is to optimize a complex system and find the best trade-offs in terms of structural requirements, footprint, position and internal volume.

Inevitably, assessing these constraints involves a large amount of cross-discipline work and requires digital collaboration, design and simulation tools. The platform makes it possible to analyze how the drone’s aerodynamics are affected when one of its elements is adjusted. Because the 3DEXPERIENCE platform enables XSun’s engineers to perform the full set of simulations as soon as the overall design is ready, they can quickly see how different design options affect the whole in structural and spatial terms.

hour flight time for the SolarXOne drone, rising to 20 hours depending on the time of take-off

The changing role of engineers in the energy sector

Cross-discipline communication also is accelerating in the nuclear industry. To support the industry’s transformation, Électricité de France (EDF) established the Switch program, to streamline and coordinate the design, construction, maintenance and decommissioning of a power plant.

Throughout a plant’s lifecycle, the program allows millions of pieces of data to be organized, shared and used by all industry participants in a simple and safe way, optimizing, harmonizing and digitalizing all engineering processes. Virtual twins will exist alongside each power plant. Switch will also integrate data that is reliable, secure and available in real time.

With these new, digital capabilities, new, more dynamic work methods are appearing. The entire industry is in flux and reinventing itself around digital technology to become more efficient, competitive and collaborative. As a result, the role of the engineer is changing. To accelerate this transformation, EDF has chosen the 3DEXPERIENCE platform as its operating model.

Transforming our business involves interacting with our ecosystem, i.e. with all of the actors: industrialists, experts, and engineers… who work with us. We want to rethink our processes, the way we do things and the way we interact around the virtual twin of our equipment/plant.