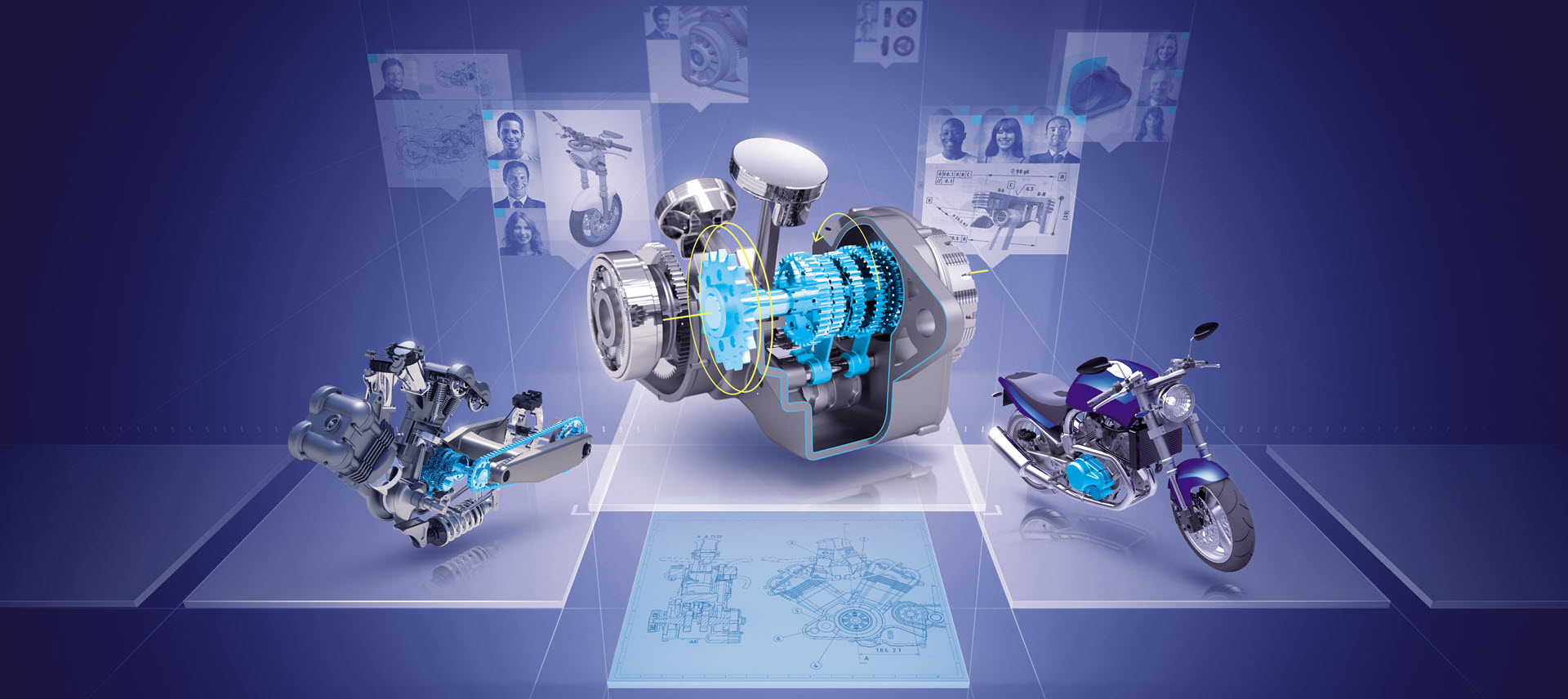

3DEXPERIENCE CATIA

Goes Beyond 3D CAD Design to Encourage Innovation Across the Extended Enterprise.

Experience the Power of CATIA on the 3DEXPERIENCE Platform

The 3DEXPERIENCE platform enables you to understand your real world better by modeling your enterprise virtually. By using powerful 3D solutions you can design, simulate, test and train your supply chain, assets, products and processes. The Virtual Twin Experience is a dynamic and accurate virtual model that allows you to assess the impact of physical changes, new products, operational processes, and disruptions. It minimizes costs and waste, while accelerating planned changes to respond to dynamic conditions.

The 3DEXPERIENCE platform offers the flexibility to perform operational procedures while enabling real-time access to actionable intelligence, traceability and reporting from your Virtual Twin Experience model.

Explore the Disciplines

Discover how 3DEXPERIENCE CATIA can help you in the various business processes and disciplines within your organization.

Delivering the Power of Virtual Twin for Architecture, Buildings, Infrastructure, and Urban Planning Projects

A Unified Industrial Design Workflow Solution

Enabling Rapid Development of High-Quality Mechanical Products

A Comprehensive Set of Engineering Roles Integrated in a Seamless Design Process

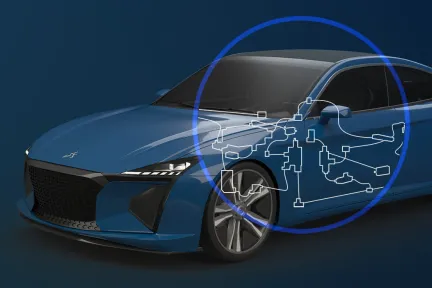

End-to-End Model-Based Solutions for Mechatronics & Software-Driven Experiences

3DEXPERIENCE CATIA software products are packaged as Roles on the 3DEXPERIENCE platform to get you up to speed faster and work more efficiently with all needed applications available at your fingertips. Select a package that corresponds to your role in an organization.

What's New in CATIA R2025x

This new Dassault Systèmes’ CATIA R2025x delivers new roles and enhancements for designers, engineers, systems engineers and construction professionals. The complete portfolio of roles is available on premise and on the public cloud and now includes more roles On Cloud than On Premise. Each new role or enhancement is developed to make your job easier and more effective at creating innovative products or experiences to shape the world we live in.

For more details, we invite you to join our CATIA User community

FAQ About Design Engineering Software

Yes, design engineers commonly use Computer-Aided Design (CAD) software as a fundamental tool in their work. CAD software allows engineers to create, modify, analyze, and optimize designs digitally. It's used across various industries including:

- automotive,

- aerospace,

- architecture,

- mechanical,

- electrical,

- and many others.

With CAD, engineers can produce detailed 2D drawings and 3D models, simulate product performance, perform finite element analysis (FEA), and collaborate with other team members on design projects. CAD has become an integral part of the design process, enabling engineers to iterate designs more efficiently and accurately before physical prototypes are built.

A Software Design Engineer is a professional who specializes in designing and developing software systems, applications, or components. They play a crucial role in the software development lifecycle, from conceptualization to implementation and maintenance.

In software engineering, architectural design refers to the process of defining the structure, behavior, and interaction of software components to fulfill specific requirements. It involves making high-level design decisions that determine the overall organization and characteristics of a software system.

System design in software engineering refers to the process of defining the architecture, components, modules, interfaces, and data for a software system to meet specified requirements. It involves translating the requirements gathered during the analysis phase into a comprehensive and detailed design that serves as a blueprint for implementing the software solution.

Learn What CATIA Can Do for You

Speak with a CATIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right CATIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering