Playing a pivotal role in sustainable development

To bring a more unified response to these crucial issues, Dassault Systèmes now addresses the Energy, Process and Natural Resources industries.

A transition towards low-carbon manufacturing, the depletion of natural resources and the destruction of ecosystems mean that mining and other energyintensive industries have a pivotal role to play in sustainable development. To bring a more unified response to these crucial issues, Dassault Systèmes now addresses the Energy, Process and Natural Resources industries through its Energy and Materials business. It provides three categories of solutions.

The first covers solutions for managing the life cycle of major infrastructure. These solutions guarantee that consistent business processes are applied when managing chemical plants, refineries and nuclear power plants. The 3DEXPERIENCE platform ensures digital continuity through governance, engineering, construction, operation and decommissioning solutions. This was the basis of the agreement signed by EDF, Dassault Systèmes and Capgemini in June 2018 to guide EDF, France’s leading electricity company, through the digital transformation of its nuclear engineering businesses. Under this 20-year partnership, the 3DEXPERIENCE platform will help standardize, harmonize and upgrade processes and engineering methods. For example, it will design digital twins of nuclear plants, whether they are in the design, construction or operational phase.

The second area of solutions concerns the life cycle of geological assets. Dassault Systèmes provides solutions to optimize the life cycle of oil and gas fields and mines, from exploration through the various stages of operation to closure. The third area involves optimizing the life cycle of materials (alloys, composites, plastics, coatings, etc.) and chemical formulas. These solutions help customers research and develop new materials from the earliest stages, qualify and formulate them, and perfect their production processes. The 3DEXPERIENCE platform is also essential in guaranteeing compliance and in safeguarding and passing on knowledge.

One way of achieving sustainable development is to increase the use of renewables in the energy mix. But the major drawback with wind and solar power is that they rely on the availability of wind and sunlight, over which we have no control. As the proportion of renewable energy gradually increases, energy storage will be the key to developing dependable ways of ensuring a continuous power supply. Meanwhile, electric vehicles will be developed on a massive scale. By offering users attractive pricing deals, electricity grid operators will take some of the power in their batteries during peak load periods and store it, or use it to manage peak demand. This is undoubtedly where the real electric energy revolution will take place. And innovative, sustainable and affordable materials will get us there.

Producing renewable electricity, and using the batteries of millions of electric vehicles to store and release it, will soon be entirely commonplace.

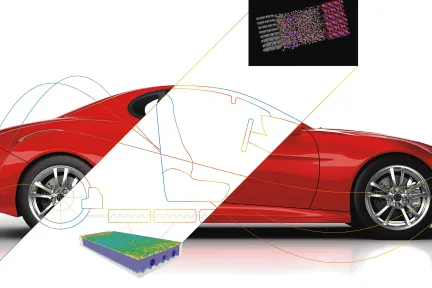

Efficient motorization for electric vehicles

The future of sustainable mobility depends largely on the development of electric vehicles. What technology should be used for their motorization? There are three main options: fuel cells, internal combustion engines coupled to electric generators and power from battery accumulators. For Dr. Menahem Anderman, founder of Total Battery Consulting, “Lithium-ion batteries have always been the technology of choice for battery electric vehicles (BEVs). Their high energy density, durability and acceptable operating temperature range make the solution very appealing.“ The range of these is the key. The most efficient vehicles now approach a range of 500 km (311 miles).

The challenge is to expand that distance so BEVs are no longer restricted to urban metropolitan areas – increasing the range while reducing charging time, because no one wants to stop for an hour to recharge their battery, even if they’re driving 1,000km. Improvements in batteries must take into account multiple variables: lower costs, increased volumetric energy density, improvements in charge acceptance rate – while respecting lifetime constraints, ease of manufacture and safety, and ecological requirements from extraction through to recycling.

The study of new materials is one way of aligning these constraints. In a lithium-ion battery, the electrodes contain an active material such as graphite or a mixed metal oxide, combined with a polymeric binder, and the electrolyte is a complex formulation of organic and organometallic materials. In the course of charging and discharging the battery, many reactions occur, leading to a change in the underlying chemistry of the battery, which can eventually lead to failure.