What is direct modeling?

Two main techniques are used in CAD design: direct modeling and parametric modeling. In this article, we investigate the direct modeling method and see exactly how and why designers, engineers, artists, and architects choose to work with it.

What is direct modeling?

Direct modeling CAD software is used to create digital representations of real or theoretical objects in three dimensions. These representations are known as 3D models. 3D models exist in digital environments exactly as objects exist in the real world. They can be manipulated, changed, viewed from any angle, and subjected to various stresses.

Using direct modeling techniques, a designer can manipulate a model in any way they wish simply by pushing and pulling at its surfaces. With direct modeling, a designer can change the form of the model quickly and easily without having to consider any kind of predetermined constraints, features, or the original design intent.

You can think of direct modeling as being very much like the process a sculptor would use when working with clay. The sculptor will start with an unformed lump of clay, then gradually manipulate the clay, take parts of it away, add to it, and form it until they get the exact shape they want. CAD direct modeling software works in just this way, except the user is working with 3D digital models rather than actual clay.

Discover the entire range of Dassault Systèmes direct modeling solutions

Discover true design freedom with the direct modeling software from Dassault Systèmes.

SOLIDWORKS xDesign

Get ready for the next generation of design solution, developed by the same team that brought you SOLIDWORKS 3D CAD

What does direct mean in direct modeling?

The development of direct modeling software was based on the concept of What You See Is What You Get (WYSIWYG). WYSIWYG allows users to manipulate content without needing to type in commands or write specific code.

Simply put, with direct modeling, a 3D model will instantly respond to any changes made by the designer. You can manipulate the model ‘directly’ into any shape you want, rather than having to work with predetermined geometric shapes.

What is the difference between direct modeling and parametric modeling?

When creating a 3D model, designers, engineers, and artists will use a direct modeling approach or the parametric solid modeling technique. What method they choose depends on both the ultimate purpose of the model and the personal preferences of the user.

While both methods make use of CAD software, there are significant differences between parametric solid modeling and direct modeling. To fully understand these differences, we need to take a brief look at what parametric CAD modeling is and how it compares to direct modeling.

What is parametric modeling?

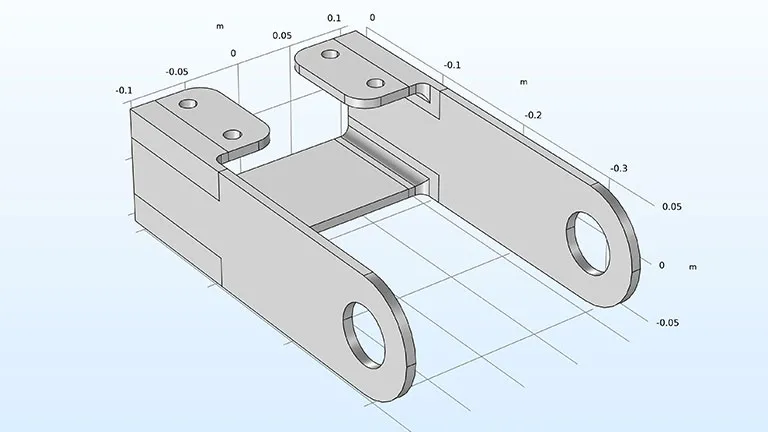

Parametric 3D modeling is the process of creating a 3D model piece by piece using shapes that have predetermined features, constraints, and parameters. Parametric 3D modeling began to be widely used in the 1980s. Previously, designers had to create shapes by inputting long and complicated calculations and commands. Parametric software now automates this process using computer-generated algorithms and equations.

When working with parametric modeling software, a designer will have a history tree that contains all the detail of the model’s features, constraints, and dimensions. Whenever a change is made, the parametric software automatically updates the model to accommodate the change.

For instance, a designer may create a room using four rectangles and then add a roof and a floor. The set parameters are that the walls must always go from the floor to the roof. If the designer changes the height of the walls, then the roof will automatically update itself to fit the new parameters and vice versa.

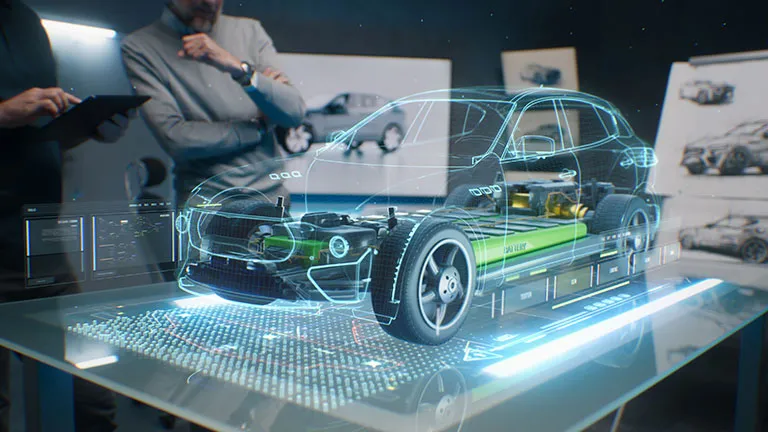

Direct modeling vs parametric modeling

Parametric modeling is often used for design work that requires precise shapes to be fitted together, such as automotive engineering or complex product designs. The relationships between parts and the impact of any changes made to the model can be effectively analyzed as the model progresses. Design intent can be easily captured using parametric CAD modeling software. Automatic updating allows for different design iterations to be done quickly with a high degree of accuracy.

Direct modeling is more of an intuitive process that is not constrained by any predetermined factors. The designer can manipulate the object as they like without having to be accurate or conform to any set rules. Direct modeling is mostly used for more artistically inclined design work such as animation or product conceptualizations.

Browse all the Dassault Systèmes store applications

We feature in our store some of our best software to design, collaborate and innovate throughout the entire product lifecycle.

Content related to Direct modeling

What are the advantages of direct modeling?

Because it is completely intuitive and allows for absolute design freedom, direct modeling is ideal for concept development, early-stage design work, organic design work, and digitally created artwork. Direct modeling is also used to remove features from a parametric model which can be highly useful in product analysis and testing.

With direct modeling software, a designer can easily modify and change a model so the entire modeling process is made faster. Designers can freely explore ideas and concepts without having to be concerned that they will break the model or be slowed down by set rules.

What are the limitations of direct modeling?

Although direct modeling does provide complete freedom of expression, it is not without its drawbacks. The flexibility of direct modeling can in itself be problematic. For example, the complete lack of parametric constraints can lead to less precision in design iterations.

There are limitations in terms of automatic design changes. With no variables and no parametric constraints, designers cannot accurately change the shape or size of the model easily or quickly.

With no history tree functionality, direct modeling has limited capabilities to document design intent and cannot record all the decisions that were taken when creating the model. For these reasons, although direct modeling is ideal for conceptualization purposes, on its own it is not suitable for complex assemblies and multi-part designs.

When would you use direct modeling?

Direct modeling can be used to work with any CAD model, from solids to wireframes, surface models, or even 2D drawings. Its flexibility and versatility make it the perfect option for a range of applications.

The ease and the speed with which a designer can manipulate shapes make direct modeling ideal for any application where aesthetics, imagination, and creativity are more important than accuracy and uniformity.

Designers and engineers make use of the design freedom provided by direct modeling software to develop product concepts and prototypes. It is often used to visualize new concepts for furniture, cars, consumer products, and even fashion. Many famous artists use direct modeling software to create NFTs, sculptures, digital artwork, and animations.

Advancements in direct modeling technology

Recent technological advancements have dramatically increased the scope of use for direct modeling software. Cloud computing integrations allow users to harness the power of multiple computers rather than just relying on one machine.

- Cloud computing

- Automation

- Virtual and augmented reality

Cloud computing

With the cloud, highly complex designs can be done faster than ever before without the expense of a large IT infrastructure. Cloud computing has also made the option of remote work viable for more people. Colleagues can communicate and collaborate no matter where they are physically located.

Automation

The rapid development of sophisticated artificial intelligence and machine learning systems has allowed software developers to enhance automated modifications and predictive design features. Initial designs and design iterations can be completed faster and with a greater level of accuracy.

Virtual and augmented reality

Virtual and augmented reality integration is being combined with direct modeling to create virtual worlds accessed via VR headsets. The film and gaming industries are currently using direct modeling in conjunction with VR and AR to develop the next generation of immersive entertainment.

Explore Dassault Systèmes solutions

Discover the powerful browser-based modeling solutions from Dassault Systèmes. You can design whatever you wish, wherever you are with 3DEXPERIENCE.

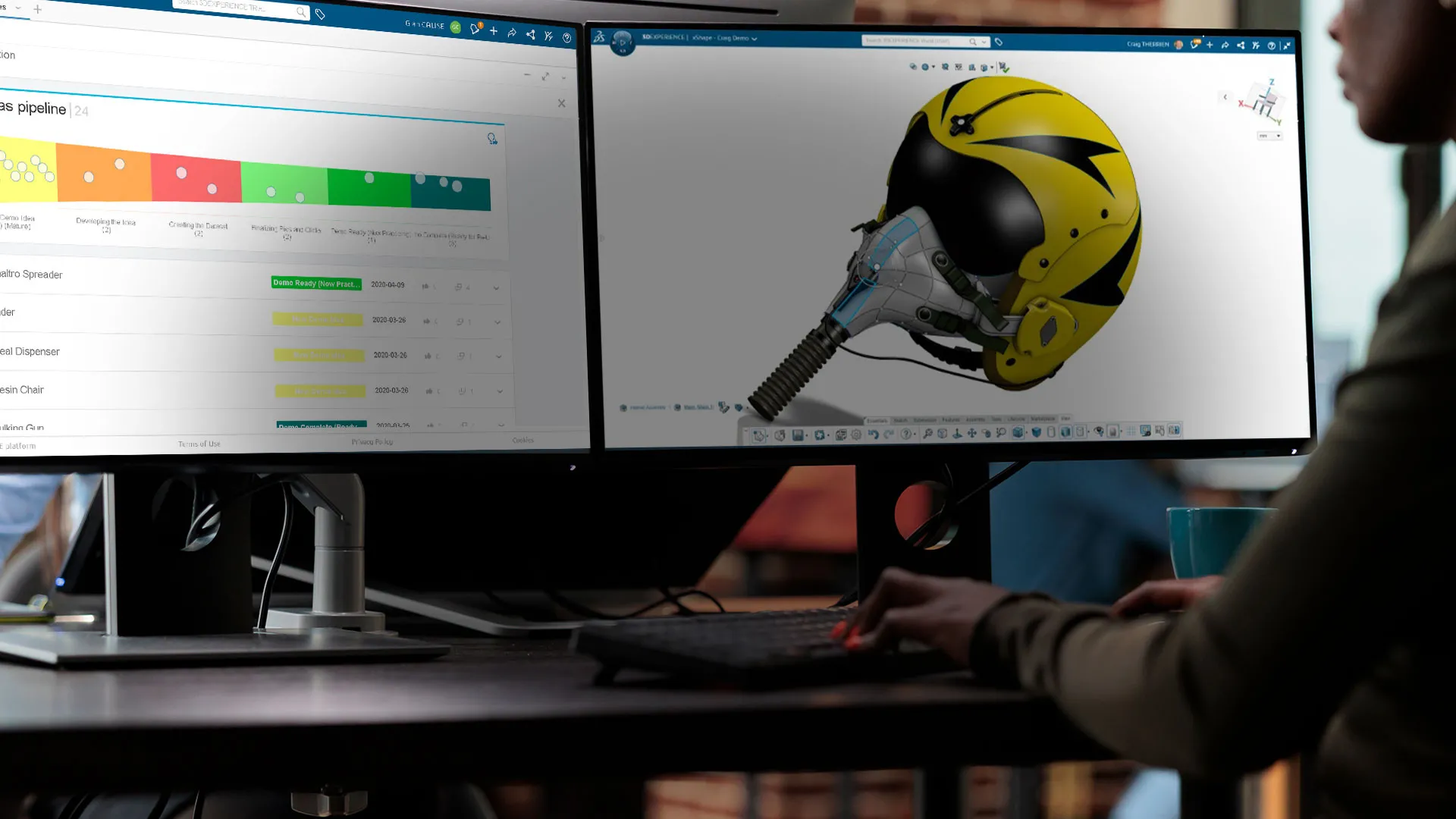

Connecting data & people to foster innovation

The 3DEXPERIENCE platform on the cloud gives you access to a various set of applications that allow you to design, simulate, inform and collaborate on a project.

Final thoughts on direct modeling vs parametric modeling

Direct modeling and parametric modeling are the two dominant methods of creating 3D models. While they are often used for different purposes, these modeling techniques are perhaps best utilized in conjunction with each other.

To create the best designs possible, engineers and designers are well advised to incorporate parametric 3D modeling software and direct modeling software into their workflows.

While the design freedom that direct modeling allows is best suited for conceptual and non-mechanical and engineering projects, it is also a key tool in product development.

An initial design produced using direct modeling can be refined with parametric modeling techniques and so brought to the manufacturing stage. The resulting parametric model can be subjected to further testing during prototyping using direct modeling techniques. Any design changes can then be made more efficient and standardized via parametric modeling.

Why choose Dassault Systèmes for your direct modeling needs?

The unmatched power of the 3DEXPERIENCE platform

To create complex, highly detailed 3D models, designers need sophisticated direct modeling software and computers with immense processing capabilities. This type of infrastructure was previously only available to commercial or industrial designers. With the development of the 3DEXPERIENCE platform, Dassault Systèmes has provided all users with the opportunity to access cutting edge CAD systems driven by the power of cloud computing.

Using the 3DEXPERIENCE platform, designers, artists, and engineers of any skill level can access enormous computing power and the entire range of Dassault Systèmes CAD software. You can connect to the 3DEXPERIENCE platform from any device, using any browser, anywhere in the world.

Benefit from over 40 years of experience

Bring your designs into reality with the help of a leading software development company. With more than four decades of experience, Dassault Systèmes has long been at the forefront of both direct modeling and 3D parametric CAD software.

Used by internationally recognized names in the aerospace and automotive industries, the tools developed by Dassault Systèmes set the standard for CAD software. Intuitive interfaces, unrivaled functionality, and versatile features provide users with the ability to create intricate, accurate, and highly complex designs for a wide range of applications.