BioIntelligence

Will your virtual twin save your life one day?

From physical to virtual models of living systems through BioIntelligence

In Slovakia, a young man is up out of his wheelchair and communicating again 9 years after he lost one-third of his skull in a fall. The breakthrough came after biomedical engineers used a 3D-printed model of his skull to design and produce a perfectly fitted implant that relieved the pressure on his brain. In Texas, conjoined twin baby girls are on their way to healthy, independent lives after surgeons carefully planned their 30-hour operation using an exact 3D model of the girls’ chest cavities and shared organs. And in London, a two-year old girl is eating, laughing and growing strong after doctors used a 3D-printed model and patch to close a hole in her heart that at first seemed simply too large to repair.

Around the world, medical teams are using 3D modeling to produce precise representations of patients’ anatomies. This enables these teams to plan and rehearse complex surgeries, and to produce live-saving implants and prostheses tailor-made for individual patients. It’s a remarkable evolution that is already having a tremendous impact in the lives of critically ill and injured.

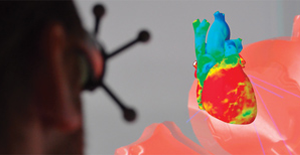

However, it’s only the tip of the iceberg. The true revolution in medicine and medical care in the 21st century will not come from such physical models, but from virtual ones. One day, these virtual models will be able to simulate the true physiology and pathophysiology of human beings – even an individual patient – changing forever the way we research, diagnose and treat injuries and disease.

Welcome to the dawn of BioIntelligence.

Medicine takes a cue from the skies

BioIntelligence brings modeling, simulation and product lifecycle management processes to life sciences

While your virtual twin may seem like a distant dream, progress in bringing this dream to life is actually already well underway in the nascent field of BioIntelligence. BioIntelligence (sometimes also called “in silico medicine” or ''computational medicine”) uses computer technologies to model, simulate, visualize and experience biological medical processes in a virtual environment (‘in silico’).

BioIntelligence aims to accurately model, simulate, and visualize biological and medical processes in a virtual environment (‘in silico’)

The inspiration for BioIntelligence can interestingly be found in complex manufacturing industries like aviation. Given the enormous cost and complexity of producing a new airplane, the aerospace industry long ago adopted a multi-disciplinary, cross-organization approach to the design and manufacturing of aircraft.

They also evolved physical prototyping and testing with virtual modeling and simulation to fully understand and predict the behavior of complex systems. This collaborative approach and use of virtual technologies fueled innovation, dramatically shortened production timelines, reduced material waste, and enabled issues in manufacturing, assembly and even maintenance to be identified and cost-effectively addressed in the virtual world, long before the first rivet was hammered.

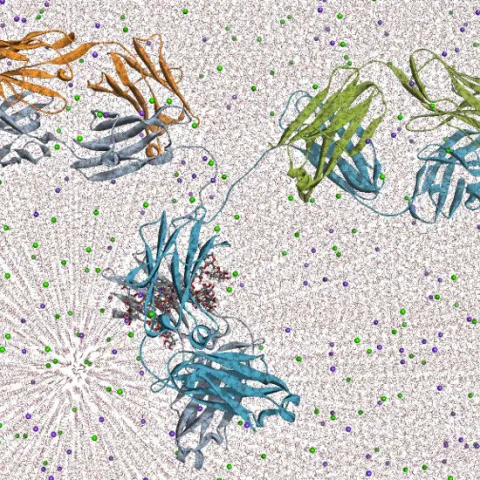

While drug makers have for some time modeled and screened virtual proteins and compounds against medical databases, drug development and production remain largely rooted in the real world, and collaboration between disciplines and organizations has been limited.

Every day, drug makers toil alone to produce real drugs that they test on real animals, and then on real patients in real clinical trials. And the time and money they expend is staggering. Drug makers today can expect to spend $2.9 billion over ten years to bring a single new drug to market (see the study by Tufts Center for the Study of Drug Development).

Add to this challenge the enormous dynamism and complexity of living systems, and it becomes clear that a collaborative approach to research and development, along with the use of virtual modeling and simulation, could bring enormous benefits to life science industries.

Collaboration between scientific disciplines and between actors like pharmaceutical companies, research labs, health service providers and computer companies would allow critical sharing of knowledge and experience to foster insight and innovation.

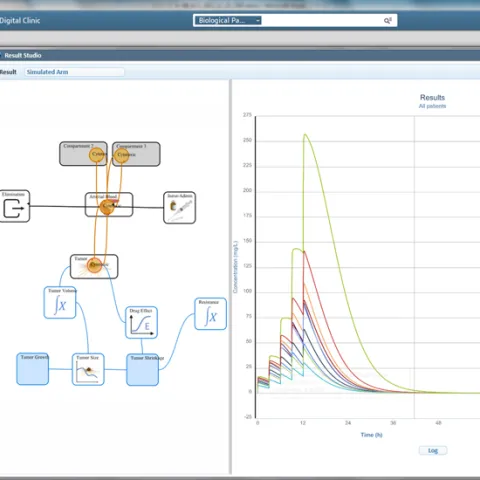

And, the collaborative use of computer models and simulation would enable researchers to better understand complex systems and more accurately predict the biological effects of the various medicines and treatments, enabling drug makers in turn to fine tune real-world assays and eliminate ineffective treatments from trials before the drugs are even produced.

In short, these changes could produce the kind of innovation and gains in efficiency, effectiveness and safety that they have brought to other industries. Such approaches could also open the door to truly personalized medicine as collaboratively produced models and simulations are infused with real world data from individual patients.

It takes an average of 10 years and $2.9 billion to bring a single new drug to market

Will we soon test virtual drugs on virtual patients in virtual clinical trials?

The groundwork is being laid now

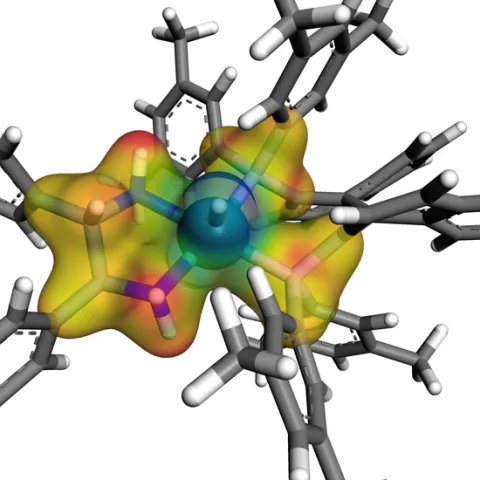

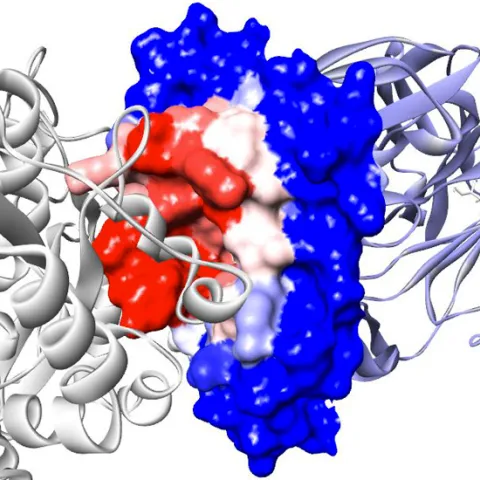

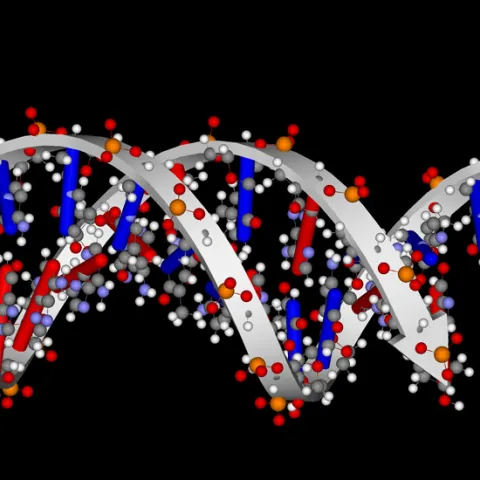

Working one’s way up the virtual pathway from molecules to cells, organs, organ systems and the whole human body will take time, and requires the modeling and simulation of discrete chemical, biological, and material entities as well as complex biological systems. But the work is already well underway.

To advance BioIntelligence technology and expertise in the life sciences, the collaborative public-private BioIntelligence Consortium has dedicated itself since 2009 to bringing the collaboration, digital modeling and simulation, and product lifecycle management (PLM) systems long-deployed in industrial sectors to the makers of medicines and medical devices. Led by Dassault Systèmes, the consortium includes industrial partners (Bayer CropScience, Ipsen, Pierre Fabre, Sanofi and Servier), bio SMBs specialists (Sobios and Aureus Pharma), and public research institutes (Génopole, INRIA, INSERM).

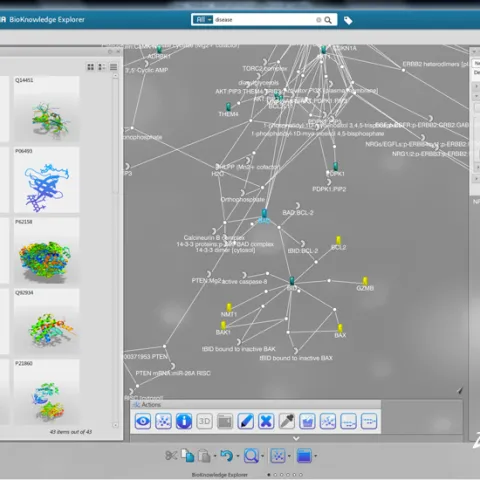

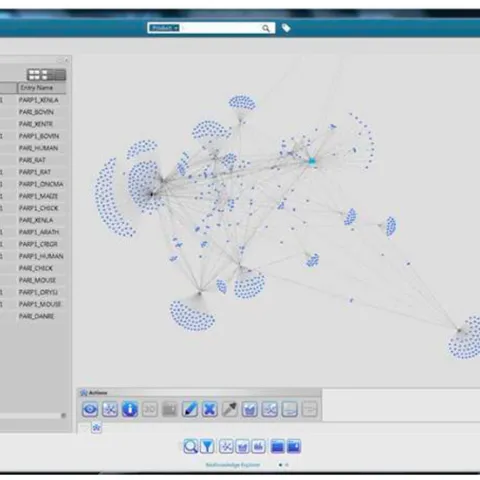

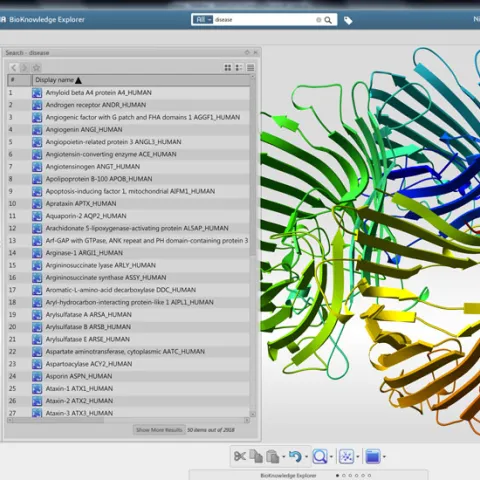

The results of this collaborative work can be seen in the Designed to Cure solution Dassault Systèmes has developed with BIOVIA BioPLM applications. The solution is designed to address the challenges and improve the efficiency and effectiveness of the drug discovery and development process. Through global scientific collaboration, scientific content federation and semantic search, and virtual modeling and predictive simulations, pharmaceutical researchers and their global ecosystem are using this solution today to quickly and more efficiently create new drugs and improve the success rate of delivering new, better targeted therapeutic solutions.

BioIntelligence Experience Day Replays

Learn more content

- Mastering BioIntelligence

- Enterprise Innovation

- Combating the Life Science Data Avalanche

- Gartner

Collaborating to address the challenges of the pharmaceutical industry

"The power of the digital world can help to fundamentally transform the industry’s current practices.” Learn more about the BioIntelligenceConsortium through the interview with Christophe Thurieau, Ipsen’s Senior Vice President of Scientific Affairs and President of Ipsen Innovation.

R&D through digitization & collaboration: A new vision for pharma

“The siloed nature of the pharmaceutical industry, as well as the absolute complexity of its research and development (R&D) activities, make it a promising market for companies in the Product Lifecycle Management (PLM) space.”

R & D Magazine, 08/10/2015

"Big data has become a growing issue in science, as these data sets are so large and complex that traditional data processing applications are inadequate. This is especially true for the life science industry, where the growing size of data hasn’t been met with tools for analyzing and interpreting this data at the same rate, leading to what many call a ‘data avalanche.’” Read the article

Dassault Systemes' Biovia Is Poised to Capture PLM Life Science Market

“Arguably, Dassault Systèmes now has the most extensive portfolio of life sciences capabilities serving the R&D and product commercialization needs of both medical device and pharmaceutical manufacturers…Biovia should have a strong impact in the R&D space for pharmaceuticals, biotechnology firms and academic research institutions. Eventually, Biovia and its customers will produce virtual models that extend to patient-specific medicines, remedies and therapies for animals and humans.” Read the report