fe-safe

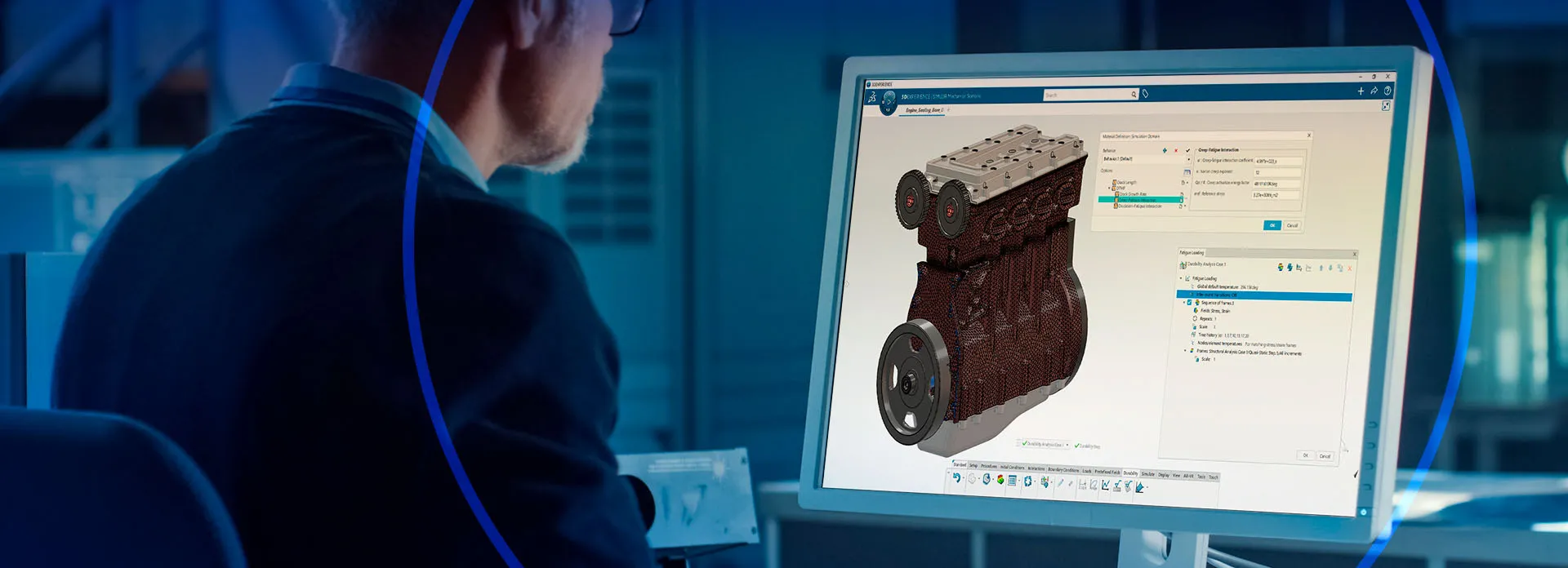

Durability Analysis Software for Finite Element Models

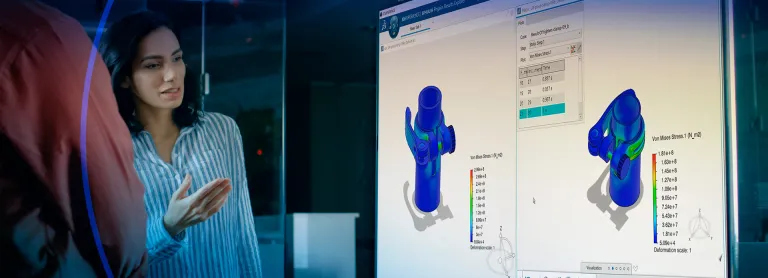

Elevate Your Designs with fe-safe's Multiaxial Fatigue Analysis

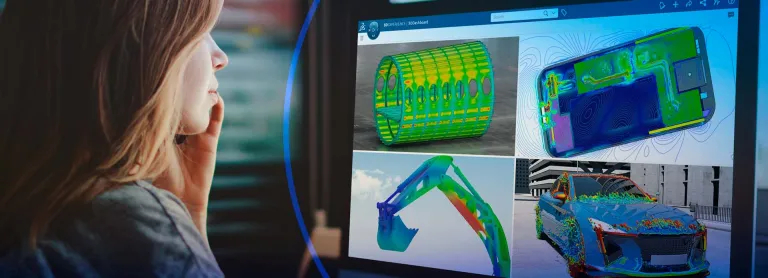

Material usage optimization has become the cornerstone of the transformation that the industry is experiencing currently. Manufacturers are relentlessly pursuing lightweight and robust components to deliver cost-efficient production with lower warranties, minimal recall costs, and accelerated timelines. Advanced finite element analysis (FEA) is a staple in design stress calculations. Whereas many companies still rely on manual stress point selection for spreadsheet analysis to conduct fatigue analysis. This approach is time-consuming and unreliable because it increases the risk of overlooking critical failure locations.

fe-safe is the technical leader in fatigue analysis software for finite element models. fe-safe continues to set the benchmark for fatigue analysis software since the early 1990s in close collaboration with the industry. The fe-safe suite of software is a world-leading technology for durability analysis from FEA. It directly interfaces with all major FEA suites (Abaqus, ANSYS, Nastran), and is capable to meet the most demanding industry applications. fe-safe was the first commercially available fatigue analysis software to focus on modern multiaxial strain-based fatigue methods and it continues to set the benchmark for fatigue analysis software. Extended Packaging includes fe-safe, allowing unified access to all solution technologies within the portfolio through a single token pool. fe-safe is popular for its accuracy, speed, comprehensive capabilities and ease of use. Regardless of the complexity of your fatigue analysis, fe-safe fits smoothly into your design process, enabling you to develop durable products.

The fe-safe suite provides:

- fe-safe: Accurate, reliable multiaxial fatigue analysis, regardless of the complexity of your loadings and model

- fe-safe/Rubber: Unique, leading-edge technology for the fatigue analysis of elastomers

- Verity Module in fe-safe: The original, patented Verity™ Structural Stress Method for seam, structural and spot-welded joints

- Smooth workflow between the SIMULIA portfolio of products: Abaqus, Isight and Tosca

fe-safe At a Glance

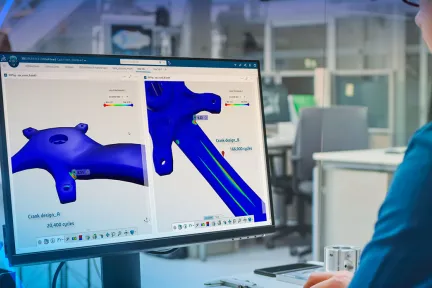

- Calculates fatigue lives at every point on a model, producing contour plots to reveal fatigue lives and crack sites without missing critical locations.

- Determines the intensity of stress change required to achieve a target design life. It highlights clearly where the component is under strength and opportunities to save material and weight.

- Estimates warranty claim curves based on probabilities of failure.

- Identifies which parts of a duty cycle are most damaging. In prototype testing this could mean shorter tests with fewer actuators.

- Accounts for manufacturing effects such as residual stresses from a stamped or formed part, or the material variation effects in castings and forgings.

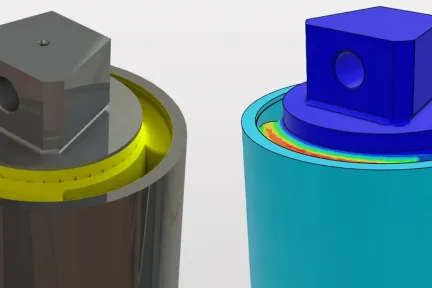

- Automatically detects contact, with contact fatigue algorithms.

- Requires no special meshing. fe-safe works from a standard free test mesh. You can combine solid and shell elements on the same model.

- Offers a unique, new method for the fatigue analysis of PSDs of loads, combining a unique method of superimposing multiaxial PSDs with critical plane analysis.

- Verity in fe-safe includes a unique calculation of the fatigue life of welded joints using the original, patented Verity Structural Stress Method.

- fe-safe/Rubber includes a unique technology for fatigue of elastomers using patented elastomer-specific algorithms.

- safe4fatigue is a powerful signal processing software included in fe-safe standard.

fe-safe Key Benefits

With the fe-safe product suite as an integrated part of your design process, you can:

- Increase the fatigue life of safety critical components.

- Optimize designs to reduce material usage.

- Reduce product recalls and warranty costs.

- Optimize and validate design and test programs.

- Improve correlation between test and analysis within a single user interface.

- Reduce prototype test times.

- Speed up analysis times, thereby reducing man-time hours.

- Increase confidence that product designs pass physical test schedules as "right-first time".

- Reduce reliance on physical testing.

Fast

- Analyze assemblies of different parts, surface finishes and materials can be in a single run - fe-safe automatically changes the method of analysis as it moves from one material to another. Avail contour plots showing the fatigue life at each node, the factor of strength, and probabilities of survival to calculate in the same run.

- Highly efficient coding, native 64-bit code, parallel and distributed processing allow fe-safe to analyze large finite element models and report results quickly. It includes parallel processing over up to eight cores as standard. Distributed processing sees near linear speed increases.

Accurate

- Advanced multiaxial algorithms are the core of fe-safe.

- Unique nodal elimination methods ensure no trade-off between speed and accuracy.

- Users consistently report excellent correlation with test results. Continuous development ensures fe-safe maintains its position as the technology leader.

User-Friendly

- fe-safe has many default settings.

- fe-safe automatically selects the most appropriate algorithm based on the selected material.

- The option to save Standard analyses, making it ideal for the non-specialist fatigue analyst.

- Equivalent specifications in the materials database allow searching on US, European, Japanese and Chinese standards.

- Highly configurable for the advanced user.

- Drive direct interfaces to leading FEA suites such as Abaqus, ANSYS and Nastran (MSC, NX) from an intuitive, single screen, Windows-based GUI.

fe-safe Technical Highlights

- Automatic hot-spot formation

- Critical distance – determining if cracks can propagate

- Damage per block

- fe-safe Custom Fatigue Algorithm (CFA)

- fe-safe/Rotate.

- Manufacturing effects

- Materials database

- Parallel processing

- Property mapping

- Signal processing

- Structural optimization

- Surface contact

- Surface detection

- Test program validation

- Vector plots

- Virtual strain gauges

- Vibration Fatigue

- Warranty curve

- Weld Fatigue

Discover the Modules

Start Your Journey NEW

Explore the technological advancements, innovative methodologies, and evolving industry demands that are reshaping the world of Durability Analysis and Finite Element Analysis. Stay a step ahead with SIMULIA. Discover fe-safe now.

Also Discover

Learn What SIMULIA Can Do for You

Speak with a SIMULIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right SIMULIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering